The global industrial sector is experiencing an unprecedented demand for sophisticated purification and separation technologies, driven by ever-tightening environmental regulations, increasing awareness of public health, and the continuous push for operational efficiency. From safeguarding drinking water quality to ensuring product purity in intricate chemical processes, effective filtration remains a cornerstone of modern industrial operations. Activated carbon filters, celebrated for their exceptional adsorption capabilities, are at the forefront of this demand, proving indispensable in removing a wide array of organic compounds, persistent pollutants, odors, colors, and residual chlorine from both liquid and gas streams. The market trajectory for these critical components points towards robust growth, fueled by global industrial expansion, particularly in emerging economies, and the stringent compliance requirements imposed by international bodies. Industries are proactively seeking next-generation filtration solutions that not only meet current performance benchmarks but also offer superior longevity, reduced maintenance, and a lower environmental footprint. This evolving landscape underscores the importance of innovations such as Activated Carbon Composite Filter Media, designed to address multifaceted challenges with enhanced efficacy and reliability, thereby providing a crucial advantage for B2B decision-makers focused on optimizing their environmental and economic performance.

The ongoing evolution within filtration technologies, especially concerning activated carbon filter for sale, is critical for tackling novel and complex contaminants, including micro-pollutants like pharmaceuticals, endocrine disruptors, and emerging per- and polyfluoroalkyl substances (PFAS). These contemporary challenges necessitate solutions that are not only highly effective at contaminant removal but also sustainable in their lifecycle, promoting options for regeneration and responsible disposal. A significant trend is the development of composite filter media, which integrate the high adsorption capacity of activated carbon with the structural stability and enhanced mechanical properties of other materials. This synergistic approach results in filters offering numerous advantages: superior filtration efficiency, extended operational life, reduced pressure drop, and improved resistance to fouling and bio-growth. Such innovations directly contribute to lower overall operational costs by minimizing energy consumption associated with pumping and decreasing the frequency of media replacement. For high-stakes industries such as food and beverage processing, pharmaceuticals, and specialized chemical manufacturing, where product integrity and public safety are paramount, these advancements in activated carbon technology are transformative, directly impacting regulatory compliance and brand credibility.

Our Activated Carbon Composite Filter Media represents a significant leap forward in adsorbent technology, meticulously engineered to transcend the limitations often associated with conventional granular activated carbon (GAC). This advanced product is designed to minimize issues such as channeling, fines generation, and excessive pressure drop, while simultaneously amplifying contaminant removal efficiency across diverse applications. The core of this innovation lies in its unique composite structure, which seamlessly integrates high-quality activated carbon particles within a resilient, porous matrix. This sophisticated design ensures optimal fluid distribution throughout the media bed and maximizes the contact time between the contaminants and the adsorbent surfaces, leading to superior adsorption kinetics and an expanded capacity for a broader spectrum of pollutants. Raw materials are carefully selected, predominantly high-grade coconut shell or coal-based activated carbon, chosen for their superior microporous structure and high iodine numbers, combined with advanced proprietary binding agents and structural components. These elements collectively impart exceptional mechanical strength and chemical stability to the media, allowing this activated carbon filter for sale to perform reliably even in aggressive chemical environments, thereby substantially reducing maintenance cycles and operational downtime for industrial facilities.

The synergistic design principles underpinning our Activated Carbon Composite Filter Media contribute profoundly to its remarkable performance attributes. The composite nature provides precise control over critical parameters such as pore size distribution and surface chemistry, enabling the media to be specifically tailored for the adsorption of targeted contaminants. This includes the effective removal of volatile organic compounds (VOCs) in industrial air streams, taste and odor compounds in potable water, or complex organic molecules from challenging industrial wastewater streams. This unparalleled adaptability positions it as an ideal solution for a multitude of applications where traditional activated carbon alone might prove insufficient or inefficient. Moreover, the robust composite structure significantly mitigates the issue of carbon fines generation, a common concern with granular media that can lead to downstream system fouling and reduced overall efficiency. The inherent durability of this activated carbon filter for sale translates into a substantially longer service life, often outperforming conventional media by a considerable margin, which directly contributes to a lower total cost of ownership (TCO) for our industrial clients, making it the preferred choice for critical applications demanding consistent and high-level purification performance.

The production of our Activated Carbon Composite Filter Media involves a highly sophisticated, multi-stage manufacturing process, meticulously engineered to ensure unparalleled consistency in quality and superior performance. The journey begins with the stringent selection of premium-grade raw materials, primarily top-tier activated carbon sourced from globally recognized suppliers committed to sustainable and ethical practices. This activated carbon undergoes precise processing, including controlled grinding and sieving, to achieve the exact particle size distribution necessary for optimal composite formation. Subsequently, these finely prepared activated carbon particles are homogeneously blended with specialized binders and structural enhancers. This mixture then advances to state-of-the-art forming techniques, which may encompass precision extrusion, advanced compression molding, or granulation, depending on the specific physical form factor and intended application of the final product. This forming stage is critically important for creating the uniform, highly stable composite structure that defines the exceptional characteristics of our media. For example, processes akin to precision engineering are employed to ensure a highly homogeneous mixture and robust mechanical integrity, effectively preventing media breakdown even under the most challenging operational conditions within diverse industrial filtration systems. Each phase of this manufacturing flow is subject to continuous, rigorous quality control inspections.

Following the formation stage, the composite media undergoes a carefully controlled curing or sintering process. This crucial step solidifies its internal structure and precisely tunes its physical and chemical properties, including its porosity, specific surface area, and mechanical resilience, which are all determinants of the filter's overall efficiency and operational lifespan. The finished product is then subjected to an exhaustive battery of performance and quality tests, strictly adhering to global standards such as ISO (e.g., ISO 9001 for Quality Management Systems) and ANSI (e.g., ANSI/NSF standards for potable water treatment chemicals). These comprehensive tests include precise measurements of the iodine number, a critical indicator of adsorption capacity, BET surface area for total active surface, comprehensive pore volume distribution, precise particle size uniformity, density, and resistance to abrasion. Furthermore, real-world performance evaluations, such as pressure drop across the media bed and precise contaminant removal efficiency for target substances, are systematically conducted on a routine basis. This meticulous quality assurance protocol ensures that every batch of our activated carbon filter for sale not only consistently meets but frequently surpasses established industry benchmarks, guaranteeing reliable, consistent, and high-performance filtration for applications demanding the most stringent purity standards. Our unwavering commitment to these rigorous protocols ensures an extended service life, typically ranging from 3 to 5 years or more depending on specific application conditions and influent quality, providing exceptional value and reliable operation for our industrial clientele.

For engineers, system designers, and procurement specialists, a thorough understanding of the precise technical parameters of Activated Carbon Composite Filter Media is indispensable for optimizing system design, predicting performance, and ensuring long-term operational efficiency. The adsorption capacity of activated carbon is typically quantified by its iodine number, which indicates its effectiveness in adsorbing small molecular weight compounds; a higher iodine number generally signifies greater microporosity and, consequently, superior capacity for removing organic contaminants. The BET (Brunauer-Emmett-Teller) surface area measurement provides a comprehensive insight into the total specific surface area available for adsorption, directly correlating with the filter's overall efficiency and contaminant loading capacity. Pore volume and pore size distribution are equally critical, as they dictate the types of molecules that can be effectively adsorbed: micropores are ideal for smaller molecules, mesopores for larger ones, and macropores facilitate bulk transport. Particle size and uniformity profoundly influence hydraulic performance, specifically the pressure drop across the filter bed; an optimally engineered particle size distribution minimizes pressure loss while maximizing the critical contact time between the fluid and the adsorbent. Density, both bulk and apparent, is essential for accurate calculation of the required media volume and understanding handling characteristics during installation and replacement. These precise specifications enable tailored applications and predictable, robust performance outcomes for any industrial setup utilizing this advanced activated carbon filter for sale.

| Parameter | Unit | Typical Value Range | Significance for Application |

|---|---|---|---|

| Iodine Number | mg/g | 900 - 1200+ | Indicator of microporosity and adsorption capacity for small organic molecules. Higher value ensures superior adsorption. |

| BET Surface Area | m²/g | 1000 - 1400+ | Total active surface available for adsorption; directly correlates with overall filter performance and efficiency. |

| Apparent Density | g/cc | 0.45 - 0.60 | Mass per unit volume; influences critical factors such as bed depth, backwash rates, and system pressure drop. |

| Hardness (Ball Pan) | % (min) | 95 | Resistance to attrition, abrasion, and mechanical degradation, ensuring exceptionally long media life. |

| Moisture Content | % (max) | 5 | Low moisture content indicates higher proportion of active material and prevents premature degradation. |

| Ash Content | % (max) | 5 | Indicates purity of the activated carbon; lower ash content generally correlates with higher performance and fewer leachable impurities. |

| Particle Size Distribution | Mesh/mm | Varies (e.g., 8x30, 12x40) | Crucial for determining optimal flow rate, minimizing pressure drop, and ensuring maximum contact efficiency. |

Beyond these foundational physical and chemical parameters, the operational performance of activated carbon filter media is further quantified by its specific adsorption efficiency for target pollutants, typically measured as breakthrough capacity, and the resulting pressure drop across the filter bed. A lower pressure drop at a given flow rate directly translates to reduced pumping energy requirements, thereby significantly contributing to overall energy savings and lower operational costs throughout the system's lifetime. The innovative composite nature of our activated carbon filter for sale is meticulously designed to optimize these crucial aspects, achieving a perfect balance between exceptional adsorption capacity and highly efficient hydraulic performance. We provide detailed performance curves and comprehensive design guidelines, based on various influent water or air qualities, which empower our clients to precisely size their systems and confidently predict contaminant removal over the filter's extended service life. Furthermore, understanding the re-activation or ultimate disposal requirements is a vital component for a complete lifecycle analysis, with our media engineered to ensure minimal environmental impact.

The remarkable adaptability and superior performance characteristics of Activated Carbon Composite Filter Media position it as an indispensable asset across an extensive array of industrial applications, effectively addressing critical purification and separation demands. In the dynamic Petrochemical Industry, these advanced filters are paramount for meticulous impurity removal from various process streams, including the vital desulfurization of natural gas, the precision purification of industrial gases, and the essential decolorization of diverse chemical products. They play a pivotal role in guaranteeing stringent product quality specifications and, crucially, in preventing the premature poisoning of catalysts, which otherwise could lead to substantial operational disruptions and costly downtime. For the Metallurgy Sector, activated carbon finds robust application in critical processes such as gold recovery (e.g., carbon-in-pulp/leach methods), the precise removal of impurities from electrolytic solutions, and the crucial mitigation of hazardous emissions originating from smelting operations. Its unparalleled ability to effectively adsorb heavy metals and complex organic compounds is particularly beneficial and widely utilized in these demanding environments. Within Water and Wastewater Treatment, arguably one of its most expansive and vital application domains, our media excels in comprehensively removing residual chlorine, disinfection by-products (DBPs) like trihalomethanes (THMs), persistent pesticides, industrial solvents, and pharmaceutical residues, thereby ensuring that treated water consistently meets the most rigorous regulatory standards for safe discharge or beneficial reuse. This comprehensive purification capability is absolutely essential for upholding public health and ensuring robust environmental protection.

Beyond these foundational industrial sectors, the expansive utility of this advanced activated carbon filter for sale extends into numerous other equally critical and specialized applications. In sophisticated Air Purification Systems, it serves as a highly effective barrier, capturing and meticulously removing volatile organic compounds (VOCs), pervasive odors, and a wide range of hazardous air pollutants from both industrial emission stacks and critical indoor air quality management systems, thereby ensuring stringent compliance with worker safety regulations and environmental protection mandates. The Food and Beverage Industry extensively relies on activated carbon for essential processes such as decolorization, and the precise removal of undesirable tastes and odors from diverse products including sugar syrups, edible oils, and alcoholic beverages, directly influencing consumer acceptance and upholding paramount product quality standards. In the highly regulated Pharmaceuticals Sector, it is an indispensable component for purifying active pharmaceutical ingredients (APIs), meticulously removing process impurities, and guaranteeing the highest possible standards of product purity and safety. A key and profound advantage of deploying our composite media in these demanding scenarios is its direct contribution to significant energy savings. This is achieved by consistently maintaining lower pressure drops across the filter bed and requiring substantially less frequent media changes, consequently reducing the energy consumption associated with pumping operations. Furthermore, the media's inherent and robust corrosion resistance guarantees exceptional longevity and consistent performance, even when subjected to highly aggressive chemical environments, collectively providing a truly robust, reliable, and economically advantageous filtration solution across the most demanding industrial operations.

When assessing industrial filtration solutions, the selection of the right `activated carbon filter supplier` is a critically strategic decision. Our Activated Carbon Composite Filter Media offers profound and distinct advantages when compared to conventional `activated carbon filter media` and the offerings of many competitors in the market. The fundamental differentiator lies in its uniquely engineered structure, which delivers vastly superior adsorption capacity synergistically combined with enhanced physical stability. While traditional granular activated carbon (GAC) is often susceptible to issues like fines generation, inefficient channeling, and higher pressure drops, our advanced composite media meticulously minimizes these inherent drawbacks due to its precisely engineered structure. This results in significantly more efficient bed utilization and extended operational cycles, directly translating to substantial reductions in operational expenditures (OpEx) for our esteemed clients. These savings encompass lower energy consumption for pumps, decreased labor costs associated with media replacement, and reduced waste disposal fees, providing a clear economic advantage. Our deep expertise, meticulously honed over more than two decades in the demanding filtration industry, enables us to provide not merely a product, but a holistic, comprehensive solution. We actively guide clients through every stage: from initial selection and precise system implementation to ongoing optimization, ensuring the long-term value and unwavering reliability embedded in every batch of our advanced activated carbon filter for sale.

Furthermore, our unwavering commitment to fulfilling the highly diverse and intricate demands of various industrial sectors extends to providing truly bespoke and highly customized solutions. We inherently recognize that each industrial application possesses its own unique set of requirements and challenges, which is why we offer meticulously tailored Activated Carbon Composite Filter Media formulations. These specialized formulations are precisely designed to target specific contaminants, optimize complex flow dynamics, or perfectly fit particular filtration system geometries. This extensive customization capability can involve fine-tuning the particle size distribution for optimal hydraulic performance, varying the precise ratio of activated carbon to the composite matrix for enhanced contaminant selectivity, or even incorporating specific chemical enhancements to boost removal efficiencies for notoriously challenging pollutants. For instance, in an industrial wastewater stream characterized by high acidity, we possess the engineering prowess to develop media with significantly enhanced pH resistance, ensuring longevity. Similarly, for a unique gas stream, we can provide media with a pore structure rigorously optimized for the capture of specific volatile organic compounds (VOCs). This highly personalized, bespoke approach guarantees maximum efficiency and cost-effectiveness, distinctly setting us apart from generic `carbon filter media` providers. Our dedicated engineering team collaborates extensively and closely with clients, leveraging a vast repository of technical knowledge and advanced simulation tools to develop filtration solutions that seamlessly integrate with existing infrastructure and consistently deliver verifiable performance improvements, thereby solidifying our authoritative position as a preferred and reliable `activated carbon filter supplier` in the global market.

Our success is fundamentally quantified and best illustrated by the measurable improvements and tangible operational efficiencies that our esteemed clients consistently achieve. A prominent case involved a large municipal wastewater treatment plant that was contending with persistently elevated levels of disinfection by-products (DBPs) and recurring taste and odor issues in their final effluent, despite deploying conventional granular activated carbon (GAC). Following the strategic transition to our advanced Activated Carbon Composite Filter Media, the plant reported a consistent and remarkable 95% reduction in Trihalomethane (THM) levels, significantly exceeding regulatory compliance mandates, and achieving a complete elimination of customer complaints regarding water quality. Furthermore, the media's extended service life, which demonstrably increased by 40% compared to their previously utilized media, translated into substantial annual savings on media replacement costs and associated labor expenditures. Another compelling illustration of our impact comes from a major chemical manufacturing facility that was grappling with challenging volatile organic compound (VOC) emissions from their ventilation system. Our customized composite media solution was seamlessly installed, leading to a rigorously measured 98% reduction in specific hazardous air pollutants. This pivotal achievement not only enabled the facility to achieve full compliance with stringent local environmental regulations but also allowed them to proactively avoid substantial regulatory fines and penalties. These real-world examples profoundly underscore the practical impact and unwavering reliability of our activated carbon filter for sale solutions, providing clear, demonstrable returns on investment through enhanced operational performance and robust regulatory adherence.

Consistent and positive feedback from client testimonials invariably highlights the long-term intrinsic value and robust performance of our Activated Carbon Composite Filter Media. A project manager from a multinational oil and gas company provided compelling feedback, stating, "The strategic transition to their composite `carbon filter media` substantially alleviated our maintenance burden and significantly improved the quality of our critical recycled process water, directly contributing to our overarching corporate sustainability goals. The observed reduction in pressure drop also meant that our pumps consumed considerably less power, leading to tangible and quantifiable energy savings across our operations." Such invaluable feedback unequivocally reinforces our core commitment to delivering not merely a product, but a comprehensive solution that fundamentally enhances operational efficiency and elevates environmental performance standards. These numerous success stories are firmly built upon a robust foundation of rigorous internal and external testing, unwavering adherence to stringent international standards such as ISO 9001 quality management and relevant environmental certifications, and the dedicated, proactive support provided by our expert technical team that offers continuous, ongoing assistance. Our extensive and long-standing partnerships with leading industrial players across a multitude of diverse sectors serve as irrefutable testament to our authoritative standing in the global market as a reliable and trusted `activated carbon filter supplier`, perpetually committed to pushing the boundaries of cutting-edge filtration technology.

Establishing profound trust and delivering unparalleled, proactive support are fundamental cornerstones of our client relationships. We fully comprehend that investing in advanced filtration solutions constitutes a significant strategic decision for B2B entities, and our unwavering commitment extends far beyond the initial point of sale. All our Activated Carbon Composite Filter Media products are backed by a comprehensive warranty, meticulously covering material integrity and performance for a specified period or throughput volume, thereby providing invaluable peace of mind to our esteemed clients. Our delivery protocols are meticulously designed for maximum efficiency and unwavering reliability, with clear and transparent lead times communicated upfront and robust logistics networks ensuring timely and secure delivery worldwide. For standard orders of `activated carbon filter media`, typical lead times range from a prompt 2 to 4 weeks, while highly custom formulations may require an additional 1 to 2 weeks for specialized production and rigorous quality assurance. We strategically maintain substantial inventory levels of our standard `activated carbon filter media` to facilitate exceptionally rapid deployment for urgent or unexpected requirements. Our transparent communication channels and dedicated project managers ensure that you are consistently kept informed at every critical stage of the process, from initial order placement right through to comprehensive post-delivery support and beyond.

Our highly responsive and dedicated customer support team, comprised of seasoned technical experts and experienced application engineers, is readily available to provide comprehensive assistance across all phases: from initial product selection and intricate application engineering to proactive troubleshooting and critical post-installation optimization. We provide thorough technical documentation, including detailed Safety Data Sheets (SDS) and precise product specifications, ensuring complete transparency and ease of integration. Our steadfast commitment to trustworthiness is profoundly reinforced by our extensive history of successful, long-term collaborations with globally recognized Fortune 500 companies and leading industrial players across diverse sectors, unequivocally demonstrating our proven capability as a reliable, authoritative, and preferred `activated carbon filter supplier` that consistently delivers superior-quality, high-performance filtration solutions. We firmly believe in cultivating and nurturing long-term strategic partnerships that are built on a foundation of mutual trust, shared goals, and an unyielding commitment to achieving excellence in advanced filtration technology, empowering our clients to meet their most demanding purification challenges.

The escalating complexity of industrial contaminants, coupled with the growing global imperative for environmental stewardship and sustainable operational practices, unequivocally underscores the critical and evolving need for advanced, resilient filtration solutions. Our Activated Carbon Composite Filter Media represents a pivotal and significant leap forward in this crucial domain, offering an unparalleled combination of efficiency, extended longevity, and remarkable versatility across an expansive array of demanding industrial applications. By effectively minimizing operational costs through reduced energy consumption and prolonged media life, significantly enhancing product purity to meet the most stringent standards, and ensuring robust regulatory compliance, this sophisticated activated carbon filter for sale provides a compelling and verifiable value proposition for discerning B2B clients who prioritize both performance and sustainability. Our unwavering commitment to continuous innovation, rigorous and transparent quality control measures, and dedicated, proactive customer support firmly establishes us not merely as a high-quality supplier but as a strategic, long-term partner in achieving your most ambitious operational and environmental objectives. We sincerely invite you to collaboratively explore how our cutting-edge filtration solutions can fundamentally transform your existing purification processes, leading to demonstrably greater efficiency, a reduced environmental footprint, and ultimately, enhanced profitability and sustained competitive advantage in your respective market.

Thickness:0.2-6 mm or Customized

Strand Thickness:0.5-8mm

Swd:2.5-100mm Lwd: 4.5-200mm

Surface Treatment:Powder Coated,Galvanized

MATERAL: PHENOLIC PAPER

MELT-BLOWN PBT

NON-WONEN LAMINATES

DIESEL FUEL FINE FILTERATION GRADE

APPLICATION : FUEL OIL WATER SEPERATION FILTER MEDIA

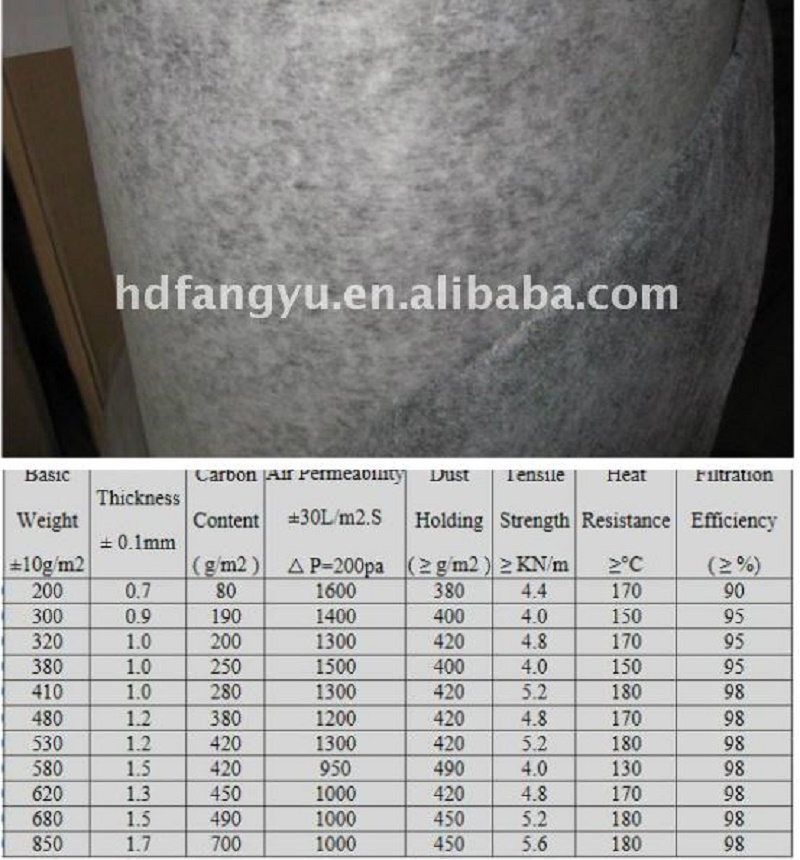

Material: Electrostatic cotton with activated carbon

PET/PP with Activated Carbon

Basic weight: 200-800g/m2

Application: Cabin Air Filters Panel Air Filters, Filter Cartridge, etc.

RAW MATERIAL: Polypropylene

PROCESS TECHNOLOGY: Melt-blown non-woven

RANGE OF EFFICIENCY: M5 ~ H11

Aug,2025,14

Aug,2025,14

Email to this supplier