This type filter paper characterized by high efficiency, low resistance and strong power, it is the first choice for National VI vehicles, and can provide the best engine protection with high precision, while meeting the demand for optimal fuel economy. The high-efficiency and long-life nanopaper for automotive applications can provide customers with better differentiated advantages and meet the air filtration requirements for engines with ultra-long service life.

Laminated Filter Paper Fuel and Water Separation

MATERAL: PHENOLIC PAPER

MELT-BLOWN PBT

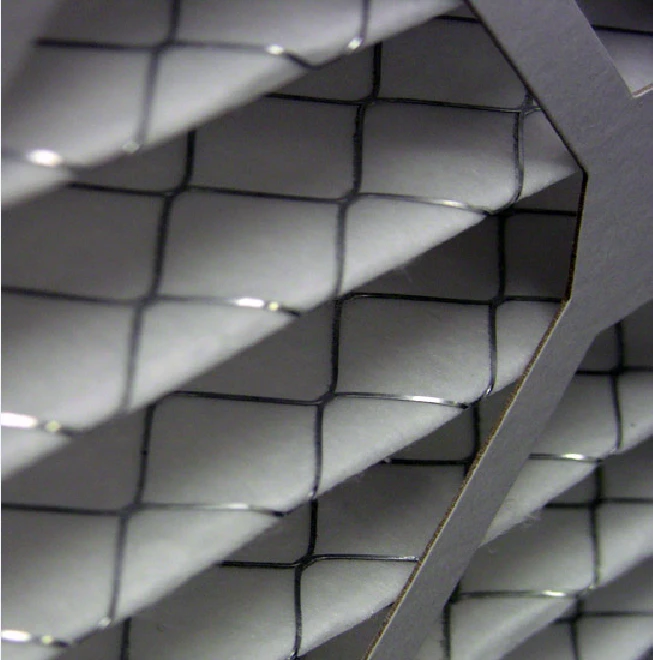

NON-WONEN LAMINATES

DIESEL FUEL FINE FILTERATION GRADE

APPLICATION : FUEL OIL WATER SEPERATION FILTER MEDIA

PET spunbond nonwovens,PBT meltblown nonwoven fabric and filter paper are molded by ultrasonic spot welding process,spunbond layer is for protection,meltblown layer is for oil-water separation and improving dusting holding capacity and filtration performance;Wood pulp paper meet the whole requirements of synthetic filter media on physical indicators and pleating,determine the final filtration performance.

|

Properties

|

Unit

|

Specification

|

|

Grammage

|

g/sqm

|

250±20

|

|

Thickness

|

mm

|

≥0.65

|

|

Burst Strength

|

kpa

|

≥400

|

|

Air permeability

p=200pa

|

L/sqm.s

|

130±30

|

|

Max Pore Size

|

μm

|

55±10

|