In an era defined by stringent environmental regulations and an escalating demand for purity, the efficacy of filtration technologies is paramount across numerous industrial and municipal sectors. Among the most versatile and indispensable solutions available, activated carbon filter for sale stands out for its exceptional adsorption capabilities. This sophisticated filter medium is engineered to remove a wide spectrum of contaminants, including volatile organic compounds (VOCs), chlorine, odors, and particulate matter, from both liquid and gas streams. Its application spans critical areas such as water purification, air quality control, and process fluid refinement, ensuring compliance with health and safety standards while optimizing operational efficiency. Understanding the nuanced attributes of different activated carbon filter media is crucial for specifying the optimal solution for specific industrial challenges, thereby achieving superior performance and longevity in demanding environments.

The demand for high-performance activated carbon water filter media continues to rise, driven by increasing global concerns over water scarcity and pollution. Industries are actively seeking reliable activated carbon filter suppliers that can provide advanced materials capable of meeting diverse and evolving filtration needs. From the initial sourcing of raw materials to the final product's rigorous quality assurance, the manufacturing process for these essential filter media is a testament to precision engineering and material science. This comprehensive guide delves into the technical specifics, applications, and competitive advantages of cutting-edge Activated Carbon Composite Filter Media, offering insights vital for B2B decision-makers and technical professionals.

The production of high-quality activated carbon filter for sale involves a meticulous, multi-stage manufacturing process designed to maximize porosity and surface area, critical attributes for effective adsorption. It begins with the selection of premium raw materials, typically high-carbon organic substances such as coconut shells, wood, or coal. These materials are chosen for their intrinsic pore structure and low ash content. The initial step is carbonization, where the raw material is heated in an inert atmosphere at temperatures ranging from 600°C to 900°C. This pyrolysis process removes volatile compounds, leaving behind a carbon char. Unlike traditional casting or forging, the process is primarily thermal and chemical, leading to a highly refined product.

Following carbonization, the char undergoes activation. This critical stage, often performed through steam or chemical activation, involves exposing the carbonized material to oxidizing gases (like steam or CO2) at elevated temperatures (700°C to 1100°C) or impregnating it with chemical agents (e.g., phosphoric acid or zinc chloride) followed by heating. This creates an intricate network of micropores and mesopores, significantly increasing the internal surface area—up to 1500 square meters per gram. This expanded surface area is what gives carbon filter media its remarkable capacity to capture molecular contaminants through van der Waals forces. Each batch undergoes rigorous testing against international standards such as ISO 9001 for quality management and ANSI standards for performance, ensuring product consistency and reliability for a long service life.

The effectiveness of an activated carbon filter for sale is quantifiable through several key technical parameters. These metrics allow engineers and procurement specialists to precisely match the filter media to specific application requirements, ensuring optimal performance and cost-efficiency. Key parameters include iodine number, which indicates the micropore volume and effectiveness for small molecule adsorption; surface area (BET method), a measure of total accessible area for adsorption; and apparent density, crucial for calculating bed volume and predicting pressure drop. These parameters are rigorously tested and validated in compliance with industry standards, providing transparency and reliability.

| Parameter | Unit | Typical Value (Coconut Shell Based) | Significance |

|---|---|---|---|

| Iodine Number | mg/g | 900 - 1100 | Indicates micro-pore activity and capacity for small molecules like iodine. Higher is better. |

| Surface Area (BET) | m²/g | 1000 - 1400 | Total accessible pore surface area. Direct correlation with adsorption capacity. |

| Apparent Density | g/cm³ | 0.45 - 0.55 | Indicates mass per unit volume; affects bed weight and pressure drop. |

| Ash Content | % | < 3 | Inorganic impurities. Lower is better for purity-sensitive applications. |

| Moisture Content | % | < 5 | Residual water in the pores. Affects actual activated carbon content. |

| Hardness (Abrasion) | % | > 95 | Resistance to mechanical wear during backwash or handling. Important for filter bed integrity. |

These specifications confirm the filter media's capability for superior performance in various conditions. For instance, an activated carbon filter for sale with a high iodine number is excellent for removing small organic molecules from drinking water, while a high surface area ensures broad-spectrum contaminant removal. Our Activated Carbon Composite Filter Media is specifically engineered to achieve optimal values across these critical parameters, providing a robust and efficient solution for complex filtration challenges in industries like petrochemical, metallurgy, and municipal water treatment, where issues like corrosion and energy consumption are critical considerations.

The adaptability of activated carbon filter for sale makes it an indispensable component across a multitude of industrial and commercial applications. In municipal water treatment, it effectively removes chlorine, chloramines, and disinfection byproducts, improving taste and odor. For industrial wastewater treatment, it targets complex organic pollutants, ensuring discharge compliance. The petrochemical industry leverages it for refining processes, removing impurities from process streams and preventing corrosion in sensitive equipment. In the metallurgy sector, activated carbon filter media plays a vital role in recovery processes and environmental control, ensuring both product purity and regulatory adherence.

Beyond traditional uses, modern composite activated carbon media offers enhanced technical advantages. Its high adsorption kinetics allow for faster processing times and smaller equipment footprints, leading to significant energy savings. The superior chemical resistance of certain formulations helps in anti-corrosion applications, extending the lifespan of filtration systems and reducing maintenance costs. Furthermore, the regenerative capabilities of some advanced carbon filter media types enable longer service intervals, minimizing waste and promoting sustainability. These attributes underscore why choosing the right activated carbon filter suppliers is a strategic decision for any operation aiming for efficiency and environmental responsibility.

When evaluating activated carbon filter suppliers, it is imperative for B2B stakeholders to consider not only product specifications but also manufacturing capabilities, quality control protocols, and comprehensive customer support. Leading suppliers differentiate themselves through adherence to global standards like ISO 14001 for environmental management and FDA compliance for food-grade applications, where applicable. A key differentiator is the ability to provide customized solutions. While many offer standard activated carbon filter for sale options, truly expert suppliers engage in a collaborative process to develop bespoke filter media tailored to unique industrial challenges.

This customization might involve developing activated carbon with specific pore size distributions for selective adsorption, impregnating the media with catalysts for enhanced chemical reactions, or formulating composite materials for multi-contaminant removal. Our company, with over 15 years of experience in the filtration material sector, prides itself on its robust R&D capabilities and a track record of successful partnerships with major industrial clients worldwide. Our commitment to continuous innovation ensures that our Activated Carbon Composite Filter Media consistently meets the evolving demands of our clients, providing not just a product, but a strategic advantage in their operations. This dedication to custom engineering sets us apart in the competitive landscape of activated carbon filter media provision.

The real-world efficacy of activated carbon filter for sale is best illustrated through successful application examples. Consider a recent project for a large-scale municipal water treatment plant facing challenges with persistent taste and odor compounds in their source water. By implementing our Activated Carbon Composite Filter Media, the plant achieved a 98% reduction in these compounds, significantly enhancing water palatability and meeting stringent consumer quality standards. This solution also demonstrated an extended service life of 2.5 years before media replacement, exceeding the client's initial projections by 30%, which translated into substantial operational cost savings and reduced downtime.

Another notable application involved an industrial air purification system in a chemical manufacturing facility struggling with VOC emissions. The installation of a specialized carbon filter media system led to a dramatic reduction in emissions, bringing the facility into full compliance with national air quality regulations and improving worker safety. The client reported a 40% reduction in energy consumption compared to their previous system, largely due to the optimized pressure drop characteristics of our media. These tangible results underscore our expertise and experience in delivering high-impact filtration solutions. Test data and analytical reports from these projects are available upon request, providing transparent validation of our product's performance.

A: The lifespan varies depending on the specific application, influent contaminant load, and flow rate. However, our media is engineered for extended durability, often lasting 18-36 months in typical industrial water treatment scenarios. Regular monitoring and expert consultation ensure optimal replacement cycles.

A: Selection depends on factors like target contaminants, flow rate, temperature, and required purity levels. Our technical sales team provides comprehensive consultation, including adsorption isotherm testing, to recommend the ideal activated carbon filter for sale that meets your exact specifications.

A: We maintain robust inventory levels and efficient logistics to ensure prompt delivery worldwide. Standard lead times typically range from 7-14 business days for common orders, with expedited options available for urgent requirements. Large or custom orders will have specific lead times communicated at the quotation stage.

Our commitment to customer satisfaction extends beyond product delivery. We offer extensive post-sales support, including technical assistance, troubleshooting, and performance optimization guidance. Every batch of activated carbon filter media is accompanied by a comprehensive quality assurance certificate. We stand by the quality of our products with a robust warranty policy, typically covering material and manufacturing defects for a period of 12-24 months from installation, ensuring long-term peace of mind for our industrial partners. Our dedicated support team is available to assist with any queries or challenges, reinforcing our position as a trusted activated carbon filter suppliers.

The selection of an appropriate activated carbon filter for sale is a critical decision that directly impacts operational efficiency, environmental compliance, and product quality across a myriad of industrial processes. By focusing on advanced manufacturing techniques, stringent quality control, and a deep understanding of application-specific requirements, the Activated Carbon Composite Filter Media represents a pinnacle of filtration technology. Its superior adsorption capacity, extended lifespan, and versatility make it an optimal choice for demanding applications in water treatment, air purification, and chemical processing. Partnering with a reputable supplier that offers customized solutions and unwavering technical support is paramount to unlocking the full potential of these indispensable filtration assets.

We invite B2B decision-makers and technical specialists to explore how our high-performance carbon filter media can address their unique filtration challenges and contribute to their operational excellence.

Thickness:0.2-6 mm or Customized

Strand Thickness:0.5-8mm

Swd:2.5-100mm Lwd: 4.5-200mm

Surface Treatment:Powder Coated,Galvanized

MATERAL: PHENOLIC PAPER

MELT-BLOWN PBT

NON-WONEN LAMINATES

DIESEL FUEL FINE FILTERATION GRADE

APPLICATION : FUEL OIL WATER SEPERATION FILTER MEDIA

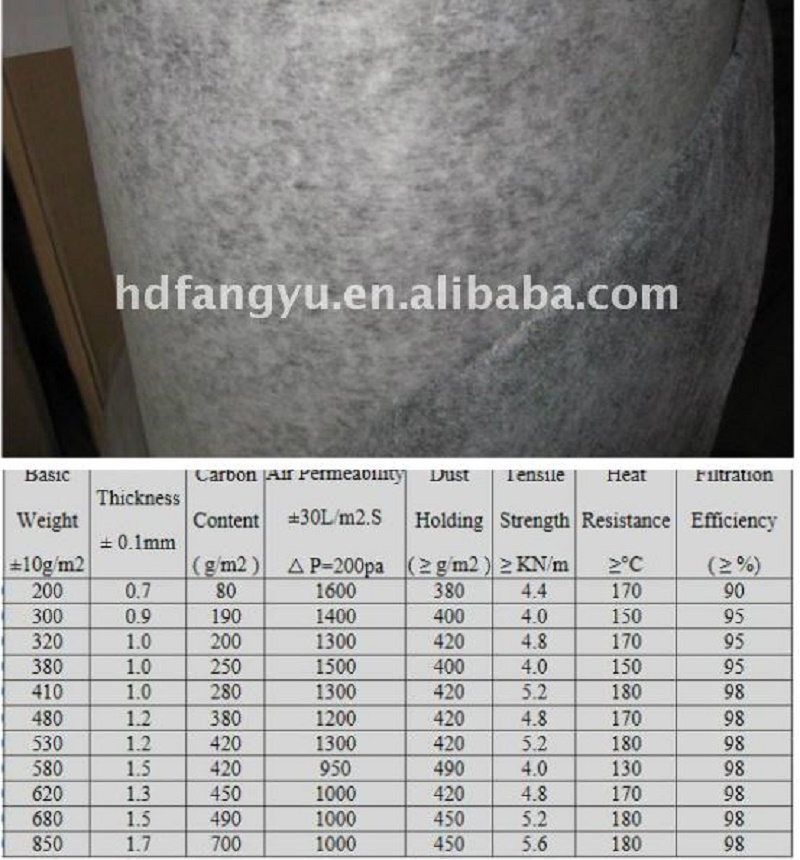

Material: Electrostatic cotton with activated carbon

PET/PP with Activated Carbon

Basic weight: 200-800g/m2

Application: Cabin Air Filters Panel Air Filters, Filter Cartridge, etc.

RAW MATERIAL: Polypropylene

PROCESS TECHNOLOGY: Melt-blown non-woven

RANGE OF EFFICIENCY: M5 ~ H11

Jul,2025,31

Jul,2025,31

Jul,2025,31

Jul,2025,31

Email to this supplier