(bulk activated charcoal filter material)

The increasing complexity of water purification and air filtration systems has accentuated the necessity for advanced and reliable filtering agents. Among these, bulk activated charcoal filter material has garnered significant recognition due to its proven efficiency and scalability in diverse industrial and residential settings. The worldwide activated carbon market was valued at USD 5.7 billion in 2022 and is anticipated to grow at a CAGR of 8.2% through 2030, largely driven by rising demand for water treatment and environmental controls (Grand View Research). As large-scale filtration demands rise, industries now seek not only high efficacy but also cost-effective, easily sourced, and customizable bulk solutions. This article delves into the core technical aspects, supplier comparisons, and real-world applications of bulk activated charcoal, equipping professionals and organizations with actionable insights for making an informed choice.

Activated charcoal is made by subjecting organic materials—usually wood, coconut shells, or coal—to controlled high-temperature processes that yield a highly porous form of carbon. The resulting structure greatly enhances adsorptive surface area, often up to 3,000 m² per gram, enabling it to effectively trap contaminants through physical adsorption and chemical interaction. In water filtration, bulk activated charcoal filter material removes organic compounds, chlorine, offsets taste and odor, and captures micropollutants, including pesticides and pharmaceuticals. Air purification applications further benefit from its ability to adsorb volatile organic compounds (VOCs) and sulfur compounds.

The role of macropores, mesopores, and micropores is vital—micropores deliver high adsorption for low molecular weight pollutants, while larger pores permit rapid transit of water or air and reduce flow resistance. The capacity and speed of filtration depend not only on the base material but also on the activation method (physical or chemical) and the quality control standards maintained during production.

Data from peer-reviewed studies show that a single gram of high-quality activated charcoal can remove up to 90% of typical household pesticides from one liter of water in under 10 minutes. This remarkable efficiency, along with regeneration/reusability (through thermal or chemical methods), makes bulk charcoal filter material a mainstay in progressive filtration system design.

When evaluating filtration agents for large-scale or continuous-operation systems, bulk charcoal filter materials present several distinct advantages over granular activated carbon (GAC) and synthetic polymer media:

Technical enhancements, including impregnated carbon (with silver or potassium permanganate), deliver targeted removal of bacteria or specific industrial gases, expanding the material’s functionality across diverse sectors.

Selecting a supplier of bulk activated charcoal for water filters or air purification is crucial, as consistent performance hinges on manufacturing standards, raw material selection, and product certification. Below is a comparative table featuring data from three major global providers, illustrating differences in technical parameters, certifications, and pricing.

| Manufacturer | Base Material | Adsorptive Area (m²/g) | Certification | Price (USD/kg) | Max. Particle Size (mm) | Regeneration Cycles | Lead Time |

|---|---|---|---|---|---|---|---|

| CarbonPure Solutions (USA) | Coconut Shell | 2,800-3,100 | NSF, ISO 9001 | 2.50 | 0.45 | 8 | 3 weeks |

| GreenFil Tech (EU) | Bituminous Coal | 2,700-2,900 | REACH, WQA | 2.10 | 0.53 | 7 | 5 weeks |

| AsiaChar Labs (China) | Wood | 2,300-2,500 | ISO 14001 | 1.90 | 0.60 | 6 | 2 weeks |

For potable water systems, coconut-based materials (with higher adsorptive area and NSF certification) are preferred. However, industrial buyers sometimes prioritize cost efficiency and rapid lead times, benefiting from wood-based products, despite the slightly lower adsorption rating.

Not every filtration challenge can be met with standard bulk activated charcoal for water filters. Industries such as semiconductor, pharmaceutical, food and beverage, and high-purity chemical manufacturing require custom solutions—either by modifying the pore-size distribution, infusing surface chemistry, or designing blends for simultaneous removal of multiple contaminants.

These customizable options empower operators to achieve target removal rates with documented consistency. For instance, a beverage bottling client realized a 98% reduction in chloramine and taste-odor compounds after deploying a tailored charcoal and KDF media blend.

The versatility of bulk activated charcoal filter material makes it indispensable to a wide spectrum of industries. Real-world applications show consistent improvements in safety, compliance, and operational efficiency.

These case studies underscore the material’s adaptability, as well as the cost and compliance benefits realized across sectors.

As environmental regulations tighten and process demands escalate, the role of bulk activated charcoal filter material has become pivotal. When procured from reputable, quality-certified sources, and appropriately customized, this filtration medium achieves cost savings, protects critical processes, and delivers sustainable environmental benefits over repeated cycles. The data and comparative insights presented affirm that, while several materials can be deployed for filtration, few offer the proven performance, adaptability, and economic value encapsulated in bulk activated charcoal for water filters and air purification systems. Assessing your facility or application’s precise requirements against the technical and logistical profiles of available options ensures safe, compliant, and efficient operation for years to come.

(bulk activated charcoal filter material)

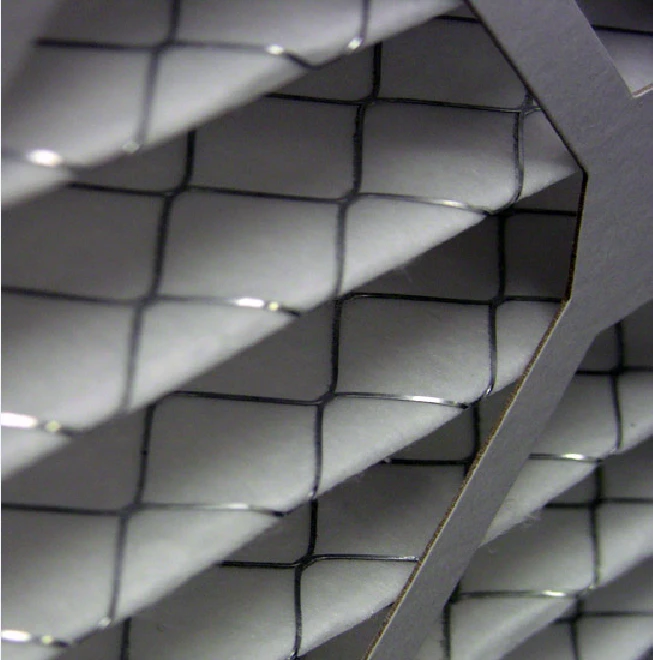

Thickness:0.2-6 mm or Customized

Strand Thickness:0.5-8mm

Swd:2.5-100mm Lwd: 4.5-200mm

Surface Treatment:Powder Coated,Galvanized

MATERAL: PHENOLIC PAPER

MELT-BLOWN PBT

NON-WONEN LAMINATES

DIESEL FUEL FINE FILTERATION GRADE

APPLICATION : FUEL OIL WATER SEPERATION FILTER MEDIA

Material: Electrostatic cotton with activated carbon

PET/PP with Activated Carbon

Basic weight: 200-800g/m2

Application: Cabin Air Filters Panel Air Filters, Filter Cartridge, etc.

RAW MATERIAL: Polypropylene

PROCESS TECHNOLOGY: Melt-blown non-woven

RANGE OF EFFICIENCY: M5 ~ H11

Email to this supplier