In the intricate landscape of industrial and commercial air purification, the choice of filtration media is paramount, directly influencing air quality, system efficiency, and operational costs. Traditional filtration solutions, while serving their purpose, often fall short in meeting the stringent demands of contemporary environments. This exigency has propelled the industry towards advanced materials, with synthetic filter media emerging as a cornerstone of high-performance air filtration. These engineered non-woven fabrics offer a confluence of superior efficiency, extended service life, and robust resistance to environmental stressors. Unlike their natural counterparts, synthetic media are meticulously designed at a microscopic level to optimize particle capture, minimize pressure drop, and provide consistent performance even under challenging conditions. This technological leap addresses critical industry challenges, from reducing energy consumption in HVAC systems to safeguarding sensitive manufacturing processes from particulate contamination. The inherent versatility of synthetic compositions, primarily polypropylene and polyester, allows for tailored solutions across a spectrum of applications, enhancing air quality and operational reliability across diverse sectors. Understanding the fundamental attributes and benefits of these advanced materials is crucial for procurement specialists, engineers, and facility managers striving for optimal air filtration outcomes.

The evolution of synthetic air filter media represents a significant paradigm shift, moving beyond the limitations of cellulose or glass fiber. These materials are engineered to deliver precise filtration efficiencies, ranging from coarse dust removal to capturing sub-micron particulate matter (ePM1). Their hydrophobic nature resists moisture absorption, preventing microbial growth and maintaining structural integrity in humid environments. Furthermore, the inherent strength and durability of synthetic fibers contribute to a longer operational lifespan, reducing the frequency of filter changes and associated labor costs. This longevity, coupled with lower initial resistance, translates into tangible energy savings, a critical factor for large-scale industrial and commercial operations aiming for sustainability and cost-effectiveness. The adoption of synthetic filter media is not merely an upgrade; it is an investment in a more reliable, efficient, and environmentally responsible filtration infrastructure, setting new benchmarks for air purity and operational excellence across various industries.

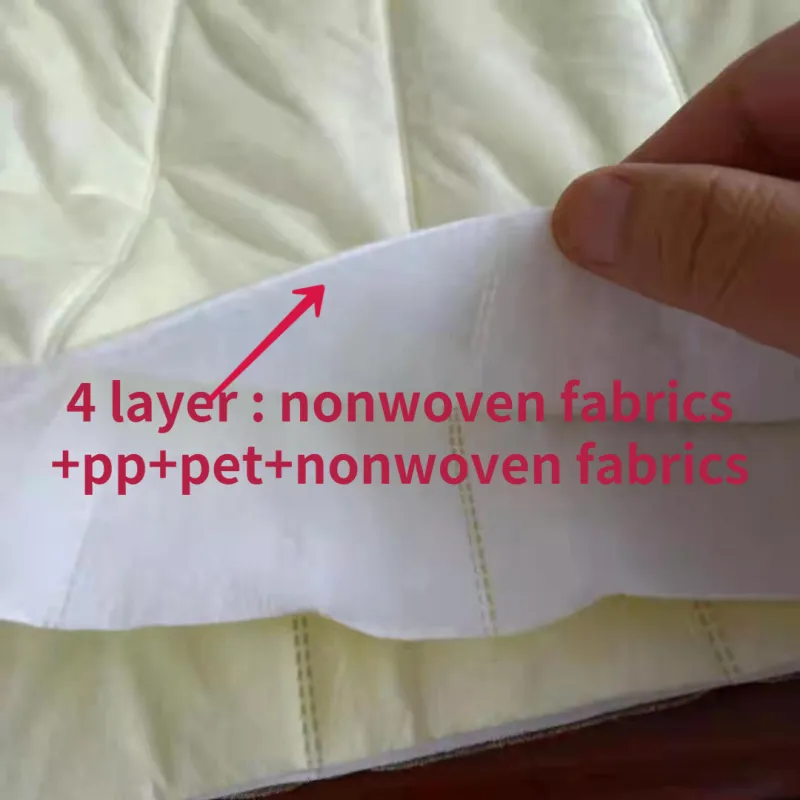

The production of high-grade synthetic filter media is a sophisticated engineering feat, involving precise control over material science and manufacturing processes to achieve desired filtration characteristics. Unlike traditional methods, the fabrication of synthetic media primarily leverages non-woven technologies, ensuring uniform fiber distribution and consistent pore size. The primary materials used are typically high-quality polypropylene (PP) and polyester (PET) fibers, selected for their inherent strength, chemical resistance, and hydrophobic properties. The core manufacturing processes include melt-blown technology, spun-bonding, and composite layering. Melt-blown is crucial for creating fine fibers (often less than 1 micrometer in diameter) with high surface area, essential for high-efficiency particulate air (HEPA) and ultra-low penetration air (ULPA) applications. This process involves extruding molten polymer through a die, then attenuating the fibers with high-velocity hot air before collecting them on a screen, forming a highly efficient filter layer.

Spun-bonding, on the other hand, produces coarser, stronger fibers, often used as support layers or for pre-filtration stages due to their excellent tensile strength and air permeability. Here, molten polymer is directly extruded into continuous filaments, which are then laid randomly on a conveyor belt and thermally bonded to form a robust non-woven fabric. Many advanced synthetic air filter media combine these techniques, forming multi-layered composites where a spun-bonded layer provides structural integrity, and a melt-blown layer ensures high filtration efficiency. This layering allows for graded density, optimizing dust loading capacity and maintaining low-pressure drop over the filter's lifespan. Post-processing can involve calendering to achieve specific thicknesses or thermal bonding to enhance fiber cohesion and durability, further tailoring the media for specific performance requirements.

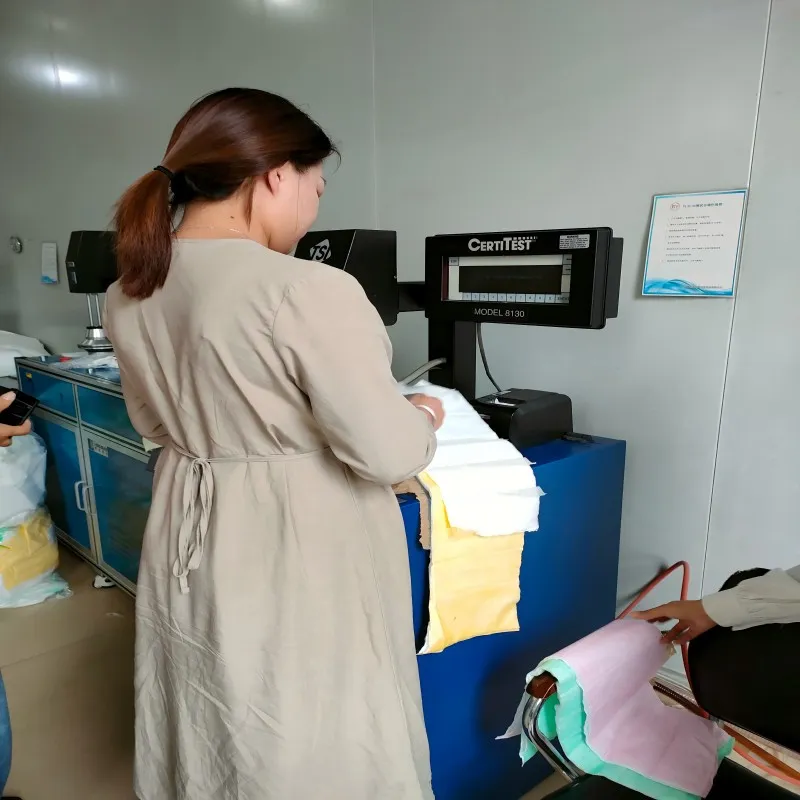

Quality control is integrated throughout the manufacturing process, adhering strictly to international standards such as ISO 16890, ASHRAE 52.2, and EN 779. These standards dictate precise testing methodologies for efficiency, pressure drop, and dust holding capacity, ensuring that each batch of synthetic filter media meets or exceeds performance specifications. Specialized equipment measures fiber diameter distribution, basis weight, air permeability, and mechanical strength. Furthermore, life cycle testing under simulated operational conditions helps ascertain the typical service life of the media, which can range from 6 months to over 2 years depending on the specific application and environmental conditions. The applicable industries where these rigorous standards are crucial include petrochemical processing, metallurgy, pharmaceutical manufacturing, food and beverage production, and sensitive electronics assembly, where air purity directly impacts product quality and operational safety. In these critical applications, the consistent quality and predictable performance of synthetic filter media are indispensable, significantly contributing to energy savings by maintaining optimal airflow with minimal pressure drop, and offering superior corrosion resistance due to the inert nature of the synthetic polymers.

The efficacy of synthetic filter media is quantified by a series of critical technical parameters, allowing engineers and procurement specialists to select the most appropriate media for specific application requirements. These parameters are rigorously tested according to international standards such as ISO 16890, which categorizes filters based on their efficiency against different particulate matter sizes (ePM1, ePM2.5, ePM10), and ASHRAE 52.2, which assigns a Minimum Efficiency Reporting Value (MERV) rating. Key performance indicators include initial pressure drop, average efficiency, dust holding capacity (DHC), and service life. Initial pressure drop refers to the resistance to airflow immediately after installation; lower values indicate less energy consumption. Average efficiency measures the percentage of particles captured over the filter's lifespan against a specific particle size range. DHC is the total mass of dust a filter can hold before reaching its terminal pressure drop, directly correlating to its service life.

| Parameter | Description | Typical Range (Synthetic Media) | Relevant Standard |

|---|---|---|---|

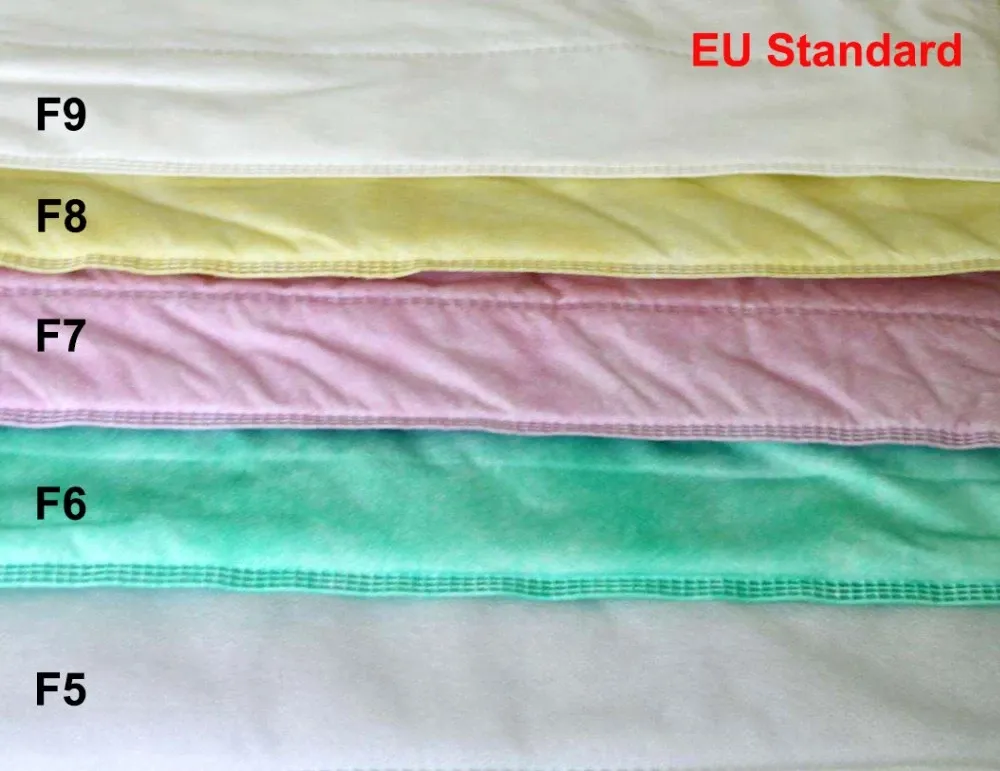

| Efficiency Rating (ISO 16890) | Measures filter performance against specific particle sizes (PM1, PM2.5, PM10). | ISO Coarse 60% to ePM1 90% (F5 to F9 / MERV 9-16 equivalent) | ISO 16890 |

| Initial Pressure Drop | Resistance to airflow when clean, indicating energy efficiency. | 10 - 70 Pa (Pascal) at nominal airflow | ISO 16890, ASHRAE 52.2 |

| Dust Holding Capacity (DHC) | Total mass of test dust captured before reaching terminal pressure drop. | 100 - 600 g/m² (grams per square meter) | ISO 16890, ASHRAE 52.2 |

| Basis Weight | Mass per unit area of the filter media. | 50 - 250 gsm (grams per square meter) | Internal QA |

| Thickness | Overall thickness of the non-woven media. | 0.5 - 5.0 mm (millimeter) | Internal QA |

| Operating Temperature | Maximum continuous operating temperature. | -40°C to 80°C (Polypropylene) | Material Data Sheets |

| Humidity Resistance | Ability to maintain performance in high humidity. | Up to 100% RH, non-hygroscopic | Material Data Sheets |

Beyond these quantifiable metrics, other significant properties include flame retardancy, which is crucial for safety in many industrial settings, and chemical resistance, ensuring the media's integrity when exposed to various airborne contaminants or cleaning agents. The choice between polypropylene and polyester synthetic filter media often depends on the specific temperature and chemical exposure conditions of the application. Polyester typically offers higher heat resistance compared to polypropylene, while polypropylene excels in moisture resistance and lower initial pressure drop for certain applications. These detailed parameters provide a transparent basis for comparison and selection, empowering B2B clients to make informed decisions that align with their operational goals and regulatory compliance requirements.

The robust and adaptable nature of synthetic filter media makes it an indispensable component across a vast array of industries, each with unique air quality and environmental control requirements. From maintaining sterile conditions in healthcare to protecting delicate machinery in heavy industry, synthetic media provide tailored solutions that ensure operational continuity and worker safety. A primary application area is Heating, Ventilation, and Air Conditioning (HVAC) systems in commercial buildings, hospitals, schools, and data centers. Here, synthetic air filter media, often configured as synthetic filter roll or pocket filters, are crucial for removing airborne particulates, allergens, and pollutants, thereby improving indoor air quality and extending the lifespan of HVAC equipment. Their low initial pressure drop contributes significantly to energy savings, a paramount concern for facility managers facing rising utility costs. The hydrophobic properties of synthetic media also make them ideal for HVAC systems in humid climates, preventing moisture-induced degradation and microbial growth, which is a common issue with traditional media.

In industrial settings, synthetic filter media provides critical protection against airborne contaminants that can compromise product quality or damage machinery. In the petrochemical industry, for example, they are used to purify air streams to prevent catalyst poisoning or equipment corrosion. In metallurgy and mining, synthetic media are integral to dust collection systems, capturing fine metallic particles and silica dust, thereby safeguarding workers' respiratory health and preventing equipment wear. The food and beverage industry relies on high-efficiency synthetic filter media to ensure hygienic air environments, preventing contamination during processing and packaging. Similarly, in pharmaceutical manufacturing and cleanrooms, ultra-efficient synthetic media are essential for maintaining ISO-classified environments, where even microscopic particles can jeopardize product sterility and efficacy.

The versatility of synthetic air filter media rolls extends to niche applications such as gas turbine air intake systems, where robust, high-efficiency media are needed to protect sensitive turbine blades from particulate erosion, improving efficiency and extending turbine lifespan. In automotive paint booths, they ensure a particle-free environment for flawless finishes. The inherent resistance of synthetic materials to moisture, chemicals, and microbial growth ensures long-term performance and reliability, even in demanding operating conditions. This corrosion resistance is particularly beneficial in environments with high humidity or chemical fumes, where traditional media might degrade rapidly. By offering sustained high performance, energy efficiency, and extended service intervals, synthetic filter media provides a cost-effective and environmentally sound solution for a broad spectrum of air filtration challenges, affirming its role as a superior choice for modern industrial and commercial applications.

While synthetic filter media offers general advantages, its application in pocket filter configurations, specifically the Synthetic Pocket Filter Media, unlocks a unique set of benefits tailored for high-volume air filtration scenarios. Pocket filters are designed with multiple, self-supporting filter pockets that inflate with airflow, creating a large surface area for dust collection while maintaining a low-pressure drop. The synthetic composition of these pockets is crucial for their superior performance. Unlike traditional fiberglass pocket filters, synthetic versions are completely shed-proof, eliminating the risk of fiber release into the clean air stream, which is a critical concern in sensitive environments like hospitals, pharmaceutical facilities, and food processing plants. This inherent structural integrity also makes them safer and easier to handle during installation and disposal, minimizing health risks for maintenance personnel.

The unique design of synthetic pocket filters, combined with the characteristics of the media, allows for a progressive density construction. This means the filter media becomes denser through its depth, capturing larger particles first and finer particles deeper within the media. This multi-stage filtration capability significantly enhances dust holding capacity, extending the filter's operational life and reducing the frequency of replacements. For instance, an F7 or F8 graded synthetic pocket filter media can handle substantial dust loads while maintaining high efficiency against PM2.5 and PM10 particles. Furthermore, the hydrophobic nature of synthetic fibers prevents moisture absorption, ensuring that the filter maintains its efficiency even in high humidity conditions and inhibiting microbial growth. This is a crucial advantage in preventing secondary air contamination and maintaining hygienic indoor air quality, which fiberglass media often struggles with in moist environments.

Comparing synthetic filter media in pocket configurations to alternative solutions highlights its superior attributes. Unlike fiberglass, synthetic pocket filters do not promote microbial growth, are resistant to shredding, and offer consistent performance over their lifespan. When juxtaposed with rigid cell filters, synthetic pocket filters often provide a larger filtration area for a given face velocity, leading to lower pressure drops and significant energy savings. Their robust construction allows them to withstand turbulent airflow and vibrations without structural degradation, making them suitable for demanding industrial HVAC systems. The ease of handling and disposal, combined with the long service life, translates into reduced maintenance costs and a lower environmental footprint. This holistic benefit profile makes Synthetic Pocket Filter Media a compelling choice for businesses prioritizing both air quality and operational efficiency.

Recognizing that no two industrial applications are identical, a leading manufacturer of synthetic filter media offers extensive customization and bespoke solutions. This capability ensures that clients receive filter media perfectly optimized for their unique operational parameters, air quality targets, and system designs. Customization options span a wide range of specifications, including media thickness, basis weight, fiber composition (e.g., specific blend of polypropylene and polyester for enhanced chemical resistance or temperature performance), and efficiency ratings (from ISO Coarse to ePM1). For instance, a client operating in a highly corrosive environment might require synthetic air filter media rolls with enhanced chemical inertness, while another in a cleanroom application might prioritize ultra-high efficiency with minimal off-gassing, demonstrating the adaptability of synthetic solutions.

Beyond basic material parameters, customization extends to the form factor of the media. Whether it's large synthetic filter rolls for automated filter lines, pre-cut sheets for specific filter frames, or tailored pocket configurations for specialized HVAC units, manufacturers can provide media in the precise dimensions and formats required. This includes options for various pleat depths, pocket numbers, and sealing methods to integrate seamlessly into existing or new filter housings. Our OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) capabilities mean we can collaborate closely with equipment manufacturers to develop proprietary filter media solutions that enhance the performance and competitiveness of their products. This co-development approach leverages our material science expertise with the client's system design knowledge, resulting in highly integrated and efficient filtration components that deliver superior performance.

The production of dependable synthetic filter media hinges on a steadfast commitment to quality assurance and adherence to global industry standards. Our manufacturing facilities operate under stringent quality management systems, certified to ISO 9001:2015, ensuring consistent product quality from raw material sourcing to final dispatch. This commitment is further demonstrated by our strict compliance with international filter performance standards such as ISO 16890 for general ventilation air filters and ASHRAE 52.2 for testing performance of particulate air filters. Each batch of synthetic air filter media undergoes comprehensive testing in accredited laboratories, both in-house and third-party, to validate critical parameters like initial pressure drop, dust holding capacity, and filtration efficiency across various particle size ranges (e.g., ePM1, ePM2.5, ePM10), guaranteeing superior performance.

Our dedication to authoritative validation extends to material composition, ensuring that the synthetic polymers used are free from harmful substances and meet industry-specific regulations, such as FDA compliance for certain food-grade applications or REACH compliance for chemical safety. We routinely conduct tensile strength tests, burst strength tests, and thermal resistance evaluations to confirm the mechanical and environmental resilience of our synthetic air filter media rolls. Pre-shipment inspections are a standard part of our protocol, where a dedicated quality control team conducts thorough visual and functional checks of the packed media to ensure it conforms to order specifications and packaging integrity. This multi-layered quality control framework minimizes deviations, guarantees product reliability, and provides our clients with unwavering confidence in the performance of every synthetic filter media product they receive. Our long-standing partnerships with leading filtration system integrators and over 15 years of service in the global market further attest to our consistent quality and reliability in delivering high-performance filtration solutions.

Our commitment to delivering superior synthetic filter media is best exemplified through the tangible successes of our diverse clientele. For over a decade, we have partnered with businesses across various sectors, enabling them to achieve optimal air quality, reduce operational costs, and enhance system longevity. One notable case involves a large-scale automotive manufacturing plant that transitioned from traditional glass fiber filters to our custom-engineered synthetic pocket filter media. Facing persistent issues with fiber shedding contaminating paint booths and high energy consumption from excessive pressure drop, the plant implemented our F8 grade synthetic pocket filters. The result was a dramatic improvement in paint finish quality due to the elimination of shed fibers, coupled with an estimated 15% reduction in HVAC energy consumption over 12 months, driven by consistently lower initial and operating pressure drops. This led to a significant return on investment within the first year, validating the long-term benefits of synthetic media.

Another success story comes from a major hospital complex that required an upgrade to its HVAC filtration system to meet more stringent indoor air quality standards and reduce maintenance burdens. By replacing their existing filters with our high-efficiency ePM2.5 rated synthetic air filter media, the hospital observed a marked decrease in airborne pathogen counts, contributing to improved patient and staff well-being. Furthermore, the extended service life of the synthetic filters, averaging 18 months compared to the previous 9 months, significantly reduced filter replacement frequency and associated labor costs. This directly translated into operational efficiencies and allowed maintenance staff to focus on other critical tasks. These real-world applications underscore the profound impact of adopting advanced synthetic filter media solutions, providing not just cleaner air, but measurable economic and operational advantages.

Synthetic filter media is manufactured from high-performance synthetic fibers, primarily polypropylene and polyester, engineered for consistent pore size, high dust holding capacity, and low-pressure drop. Unlike traditional fiberglass or natural fiber media, synthetic media is hydrophobic (resistant to moisture), shed-proof, and offers superior resistance to microbial growth and chemical degradation, leading to longer service life and better air quality.

The service life of synthetic air filter media varies depending on the specific application, dust load, airflow, and filter design (e.g., synthetic pocket filter media vs. rolls). Generally, with proper system design and maintenance, synthetic filters can last from 6 months to over 2 years, significantly outperforming many traditional media types due to their high dust holding capacity and structural integrity.

Yes, in several ways. While primarily derived from petroleum, the extended service life of synthetic filter media means less frequent replacements, reducing waste. Their lower pressure drop contributes to significant energy savings for HVAC systems, reducing carbon emissions. Furthermore, many synthetic filter media are non-toxic and can be safely disposed of in accordance with local regulations; some synthetic materials are also recyclable, contributing to a circular economy.

Absolutely. Manufacturers offer extensive customization options for synthetic filter media, including variations in basis weight, thickness, fiber composition, efficiency rating (e.g., ISO Coarse, ePM1, ePM2.5, ePM10), and physical dimensions for rolls or pre-cut sheets. This allows for precise tailoring to meet the unique performance demands of various industrial and commercial filtration systems, ensuring optimal fit and function.

Understanding the critical nature of timely delivery and reliable after-sales support for B2B operations, we have streamlined our logistics and customer service frameworks for synthetic filter media. Our global supply chain ensures efficient and secure delivery, with a typical delivery cycle ranging from 2 to 4 weeks, depending on order volume, customization requirements, and destination. For urgent requirements, expedited shipping options are available to meet demanding project timelines. We employ robust packaging solutions to protect the integrity of the synthetic air filter media rolls and pre-cut media during transit, ensuring they arrive in pristine condition, ready for immediate deployment at your facility, minimizing any potential delays.

Every batch of our synthetic filter media is backed by a comprehensive warranty, typically covering manufacturing defects and material integrity for a specified period from the date of purchase. This warranty underscores our confidence in the quality and durability of our products, providing you with peace of mind. Our dedicated customer support team comprises technical experts who are readily available to assist with product selection, technical specifications, installation guidance, and troubleshooting. We provide ongoing support to ensure optimal performance of our synthetic pocket filter media throughout its lifespan, fostering long-term partnerships built on trust and mutual success. Our commitment extends beyond sales, offering continuous technical consultation and problem-solving to meet the evolving demands of your air filtration challenges, making us a reliable partner for your filtration needs.

Thickness:0.2-6 mm or Customized

Strand Thickness:0.5-8mm

Swd:2.5-100mm Lwd: 4.5-200mm

Surface Treatment:Powder Coated,Galvanized

MATERAL: PHENOLIC PAPER

MELT-BLOWN PBT

NON-WONEN LAMINATES

DIESEL FUEL FINE FILTERATION GRADE

APPLICATION : FUEL OIL WATER SEPERATION FILTER MEDIA

Material: Electrostatic cotton with activated carbon

PET/PP with Activated Carbon

Basic weight: 200-800g/m2

Application: Cabin Air Filters Panel Air Filters, Filter Cartridge, etc.

RAW MATERIAL: Polypropylene

PROCESS TECHNOLOGY: Melt-blown non-woven

RANGE OF EFFICIENCY: M5 ~ H11

Aug,2025,14

Aug,2025,14

Email to this supplier