In an increasingly air-quality conscious world, the demand for high-performance filtration solutions is skyrocketing. At the heart of many advanced filtration systems lies melt blown filter media, a critical component renowned for its exceptional efficiency and versatility. This innovative material, often produced from polypropylene or other thermoplastic polymers, achieves superior particle capture through a unique manufacturing process that creates a dense web of microfibers. Its inherent structure allows for high filtration efficiency with relatively low pressure drop, making it indispensable across a myriad of applications from medical face masks and HVAC systems to industrial air purification and liquid filtration. Our focus today is on the advancements and specific advantages of Meltblown And Synthetic Composite Filter Media, a product engineered to push the boundaries of filtration performance, offering enhanced durability, structural integrity, and customizability for the most demanding environments.

The evolution of meltblown filter material has been driven by the need for more efficient and robust filtration solutions that can withstand challenging operational conditions while maintaining optimal performance over extended periods. Industry trends indicate a consistent shift towards materials that offer better energy efficiency, reduced waste, and longer service life, all of which are hallmarks of high-quality meltblown media. As a leading provider among melt blown filter manufacturers, we leverage cutting-edge technology and rigorous quality control to produce composite media that not only meets but exceeds global filtration standards. This proactive approach ensures that our clients receive a product that is not just effective but also provides long-term value and reliability.

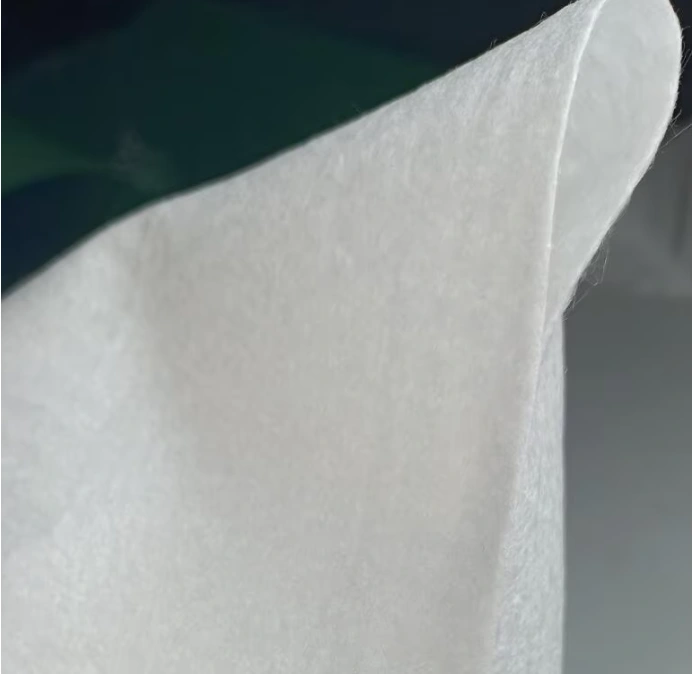

The production of high-quality melt blown filter media is a sophisticated process that begins with the precise selection of raw materials, primarily high-melt-flow polypropylene granules. Unlike traditional textile or paper-based filters, meltblown technology creates a non-woven fabric directly from molten polymer. The process involves extruding molten polymer through a die containing thousands of small orifices. Immediately upon exiting the die, the fine polymer streams are attenuated (drawn and elongated) by high-velocity hot air or gas. This high-speed attenuation stretches the fibers to micron or sub-micron diameters, significantly increasing their surface area and creating an intricate, randomly oriented fibrous web.

Following the fiber formation, these ultrafine fibers are collected on a rotating screen or conveyor belt, forming a self-bonded non-woven web. The unique aspect of our Meltblown And Synthetic Composite Filter Media lies in the subsequent lamination or integration with other synthetic layers, such as spunbond nonwovens. This composite structure imbues the final product with superior mechanical strength, better pleatability, and enhanced filtration characteristics. For instance, the synthetic backing layer provides structural rigidity, preventing deformation under high airflow, while the meltblown layer offers the high filtration efficiency. Strict adherence to international quality standards such as ISO 9001 and internal rigorous testing ensures consistency in basis weight, thickness, air permeability, and most critically, filtration efficiency and pressure drop. The composite structure also contributes to a significantly extended service life compared to single-layer media, offering excellent resistance to moisture and chemicals, thereby reducing maintenance and replacement costs in various industrial applications.

Illustration of the precise fiber formation in meltblown technology, forming dense, highly efficient media.

Understanding the technical specifications of melt blown filter media is crucial for selecting the optimal product for specific filtration challenges. Our Meltblown And Synthetic Composite Filter Media is meticulously engineered to meet demanding performance criteria. Key parameters include filtration efficiency, which quantifies the percentage of particles captured at a specific size (e.g., 99.97% at 0.3 microns for HEPA grade), and pressure drop (or air resistance), which measures the resistance to airflow through the media – a lower pressure drop indicates better energy efficiency. Basis weight (gsm), thickness, and tensile strength are also vital indicators of media quality and durability.

Here’s a table outlining typical specifications for our high-performance meltblown filter material, showcasing the range and precision involved in its production. These values are derived from extensive testing following industry standards such as ISO 16890 for general ventilation air filters and EN 1822 for HEPA/ULPA filters, ensuring authoritative and reliable data for our clients seeking top-tier meltblown media.

| Parameter | Measurement Unit | Typical Range | Description / Standard |

|---|---|---|---|

| Filtration Efficiency (ePM1) | % | 60% - 95%+ | Efficiency against fine particulate matter ( |

| Minimum Efficiency Reporting Value (MERV) | Rating | 8 - 16 | ASHRAE 52.2 standard, higher is better. |

| Pressure Drop @ 0.32 m/s | Pa (Pascals) | 15 - 80 | Resistance to airflow at a standard face velocity. Lower is more energy efficient. |

| Basis Weight | g/m² (gsm) | 20 - 200 | Weight per square meter, indicating material density. |

| Thickness | mm | 0.2 - 2.0 | Overall media thickness. |

| Tensile Strength (MD/CD) | N/5cm | > 50 / > 30 | Strength in machine direction (MD) and cross direction (CD), crucial for durability. |

These parameters collectively define the filtration performance and mechanical robustness of the media. For instance, a higher basis weight might indicate more material for filtration, but it must be balanced with pressure drop to ensure energy efficiency. The composite nature of our meltblown filter material ensures an optimized balance, offering high efficiency and low pressure drop, leading to significant energy savings and extended filter life for end-users.

The adaptability and superior performance of melt blown filter media position it as a preferred choice across numerous critical industries. In the HVAC sector, it forms the core of high-efficiency air filters (e.g., MERV 13+ or ePM1 60-95%), vital for maintaining indoor air quality in commercial buildings, hospitals, and residential spaces. Its ability to capture fine particulate matter, allergens, and airborne microorganisms directly translates into improved public health and reduced energy consumption due to lower fan load.

Beyond HVAC, our Meltblown And Synthetic Composite Filter Media excels in automotive cabin air filters, protecting passengers from pollutants and exhaust fumes. In medical and healthcare applications, especially for N95 and surgical masks, the electrostatically charged meltblown media ensures effective filtration of viruses and bacteria, meeting stringent FDA and NIOSH standards. Industrially, it is integral to liquid filtration systems (e.g., water purification, chemical processing) due to its fine pore structure and chemical resistance, and in industrial dust collection, where its robust structure and high dirt-holding capacity reduce equipment wear and ensure compliance with environmental regulations.

Diverse applications of meltblown filter media, from HVAC to personal protection.

The technical advantages are manifold:

These advantages collectively contribute to a powerful value proposition: enhanced performance, reduced operational costs, and superior protection, making our composite meltblown filter material a strategic investment for any filtration requirement.

As experienced melt blown filter manufacturers, we recognize that off-the-shelf solutions rarely fit every unique industrial requirement. Our strength lies in our ability to offer highly customized meltblown filter material and composite media solutions. This involves collaborating closely with clients to understand their specific filtration challenges, operating conditions, and performance targets. Whether it's adjusting basis weight, thickness, fiber diameter, or incorporating specialized treatments (e.g., anti-microbial, activated carbon layers), we tailor our manufacturing process to deliver media perfectly suited to the application.

Our R&D team utilizes advanced simulation and testing methodologies to predict media performance under various conditions, ensuring that customized meltblown media prototypes meet the exact specifications before full-scale production. This commitment to bespoke engineering provides our clients with a competitive edge, optimizing their filtration systems for maximum efficiency and longevity.

Tailored meltblown filter media for specialized industrial applications.

A major electronics manufacturer required an upgrade to their cleanroom HVAC filters to meet new particle count standards. Their existing filters, using standard melt blown filter media, struggled with consistently achieving the desired ePM1 efficiency without excessive pressure drop. We engineered a customized Meltblown And Synthetic Composite Filter Media with a specific fiber distribution and electrostatic charge enhancement. Post-implementation, the client observed a 15% reduction in pressure drop while simultaneously improving ePM1 efficiency from 75% to 90%, leading to significant energy savings and adherence to the stringent cleanroom classification, validating our expertise in tailored filtration solutions.

Trust is paramount in B2B partnerships, particularly for critical components like melt blown filter media. Our company upholds the highest standards of quality assurance and technical support, building a foundation of reliability with every client. We are certified under ISO 9001 for quality management systems, ensuring every batch of meltblown filter material meets precise specifications. Furthermore, our products undergo rigorous third-party testing to comply with international standards such as ASHRAE 52.2 and EN 1822/ISO 29463, providing verifiable performance data. Our laboratory is equipped with state-of-the-art particle counters, air permeability testers, and tensile strength machines, conducting continuous in-process and final product inspections.

Q1: What makes Meltblown And Synthetic Composite Filter Media superior to standard meltblown?

A1: The composite structure combines the high filtration efficiency of meltblown with the enhanced mechanical strength and durability of synthetic support layers. This leads to better pleatability, increased burst strength, and often a longer lifespan, especially in challenging applications.

Q2: What is the typical lead time for custom meltblown filter material orders?

A2: Standard orders typically have a lead time of 2-4 weeks. For highly customized solutions involving new material development or specific treatments, lead times can range from 4-8 weeks, depending on complexity and testing requirements. We maintain transparent communication throughout the entire order process.

Q3: Do you provide samples for testing before bulk purchase?

A3: Yes, we highly recommend and provide samples of our melt blown filter media for client evaluation and testing in their specific applications. This ensures complete satisfaction and validates performance expectations before committing to larger orders.

We stand behind the quality of our melt blown filter media with a comprehensive product warranty against manufacturing defects. Our dedicated technical support team is available to assist with product selection, application guidance, and troubleshooting, ensuring our clients receive ongoing value and optimal performance from our filtration solutions. This steadfast commitment to quality and service solidifies our position as a trusted partner among melt blown filter manufacturers.

Thickness:0.2-6 mm or Customized

Strand Thickness:0.5-8mm

Swd:2.5-100mm Lwd: 4.5-200mm

Surface Treatment:Powder Coated,Galvanized

MATERAL: PHENOLIC PAPER

MELT-BLOWN PBT

NON-WONEN LAMINATES

DIESEL FUEL FINE FILTERATION GRADE

APPLICATION : FUEL OIL WATER SEPERATION FILTER MEDIA

Material: Electrostatic cotton with activated carbon

PET/PP with Activated Carbon

Basic weight: 200-800g/m2

Application: Cabin Air Filters Panel Air Filters, Filter Cartridge, etc.

RAW MATERIAL: Polypropylene

PROCESS TECHNOLOGY: Melt-blown non-woven

RANGE OF EFFICIENCY: M5 ~ H11

Jul,2025,31

Jul,2025,31

Jul,2025,31

Jul,2025,31

Email to this supplier