(paint booth filter price)

The paint booth filter market has undergone substantial changes over the past decade, largely propelled by stricter environmental regulations and rising demand for high-quality finishes in industries like automotive, furniture, and electronics. The average paint booth filter price depends on multiple factors including filter type, filtration efficiency, and materials used. As of 2024, price points for standard fiberglass filters range between $1.50 and $8 per panel, while advanced multi-layer and HEPA models can cost $25 to $180 each, depending on size and rated performance.

Major industry reports indicate that the global paint booth filtration market is projected to reach $830 million by 2028, growing at a CAGR of 5.6%. This growth is underpinned by stricter VOC emission standards and needs for operational efficiency. Large-scale operators now change filters 20% more frequently than just five years ago, directly impacting annual operating budgets and driving attention toward both upfront and lifecycle filter costs. The fundamental challenge for buyers is evaluating filter price in the broader context of durability, efficiency, and regulatory compliance.

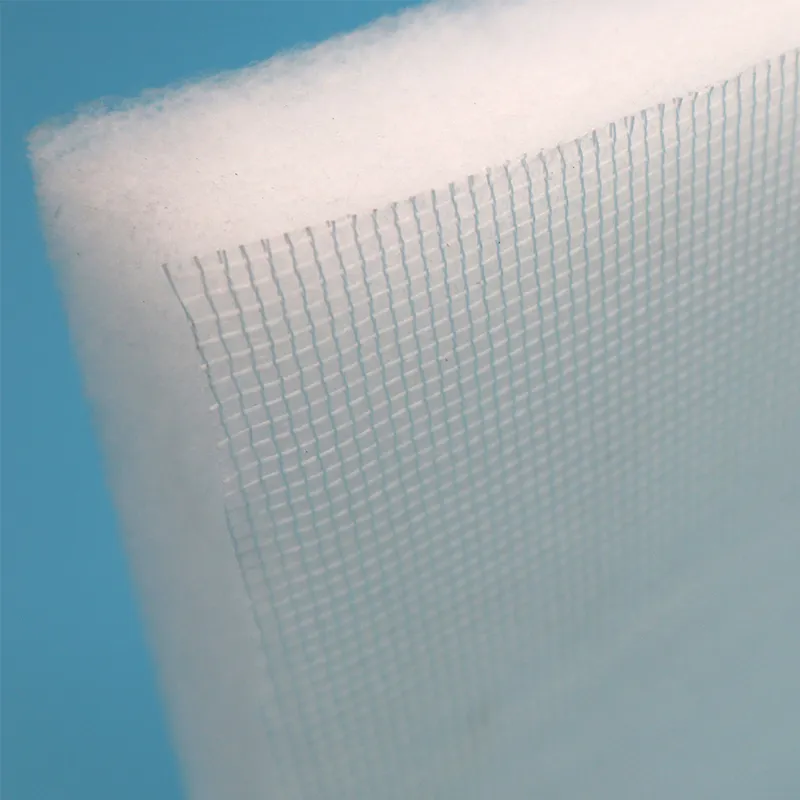

Contemporary paint booth filter technology incorporates several advancements that directly contribute to operational excellence. Key features such as multi-stage filtration, increased dust holding capacity, and optimized air-flow dynamics result in higher booth throughput and fewer process interruptions. Most notably, advancements in synthetic and nanofiber media have improved particulate removal efficiencies to levels exceeding 99.97% for sub-micron particles, dramatically reducing finish rejects and booth cleaning costs. This systemic capability allows large facilities to achieve up to 30% longer filter lifespan and an estimated 12% to 18% reduction in annual disposal expenses.

For water treatment applications, the activated carbon filter for water treatment price and its relative effectiveness are substantial considerations. Activated carbon filters have become a preferred solution for their superior adsorption capacity and ability to remove volatile organic compounds, chlorine, and other contaminants. Leading products now offer iodine numbers upward of 1200 mg/g and throughput up to 2000 gallons per day. On average, commercial granular activated carbon filter price ranges from $65 to $480 per unit, depending largely on filter volume, media grade, and system integration requirements.

While the sticker price of replacement paint booth filters is an initial focal point, total cost of ownership (TCO) encompasses several critical variables. High-efficiency filters may carry a premium price—often 2x to 3x that of basic filters—but can double airflow cycle lengths, leading to fewer shutdowns and labor costs. Additionally, energy-efficient designs can cut booth fan power consumption by up to 12%. According to field data, a typical manufacturer using 1200 filters yearly could reduce total annual filter-related costs from $54,000 with economy fiberglass options down to $39,600 with optimized high-efficiency filters, inclusive of fewer change-outs, reduced labor, and lower waste disposal fees.

Brands also differ in replacement frequency and ease-of-installation, which can affect production scheduling. Assessing long-term reliability, particle retention, and third-party testing certifications dramatically improves procurement decisions, ensuring compliance with ISO 16890 and related industry standards.

Selecting the best value requires a clear comparison among top manufacturers. Below is a detailed comparison table summarizing several leading brands for both paint booth and activated carbon filtration solutions:

| Brand | Filter Type | Efficiency (%) | Lifespan (hrs) | Single-unit Price (USD) | Annual Changeouts | Total Annual Cost (USD) | Certifications |

|---|---|---|---|---|---|---|---|

| EcoAir | Fiberglass Paint Booth | 78 | 110 | 3.90 | 12 | 46,800 | ASHRAE, ISO 16890 |

| CleanMax | HEPA Paint Booth | 99.97 | 240 | 62.00 | 6 | 44,640 | UL, ISO 16890 |

| PureTech | Multi-layer Synthetic | 92 | 180 | 18.50 | 8 | 35,520 | Eurovent, ISO 16890 |

| AquaGuard | Granular Activated Carbon | 86 | 300 | 160.00 | 4 | 25,600 | NSF/ANSI 61, ISO 14034 |

| HydroPure | Activated Carbon for Water | 91 | 350 | 195.00 | 3 | 23,400 | NSF 42, ISO 9001 |

Depends on process and contaminant load; Based on 1000 filter/year facility; In 8hr cycles for water treatment.

As demonstrated, higher upfront investment can translate to much lower annualized costs and greater operational stability, supporting the business case for advanced, certified filtration solutions.

The granular activated carbon filter price often becomes a key line item for facilities seeking enhanced water purity, whether for rinse booths, cooling towers, or upstream of deionization units. Noteworthy, average bulk purchase prices hover from $72 to $165 per filter for viable industrial granule options, but prices rise to $340 and higher for specialty or ultra-high capacity units. Recent studies report that well-maintained industrial carbon filtration setups can reduce total dissolved organic contaminants by over 85% and deliver less than 0.1 ppm residuals, vastly improving downstream equipment reliability and finish consistency in electrocoating or painting applications.

Adoption of innovative pre-activation and micro-porosity control processes by manufacturers, such as steam-activation at 900°C, has resulted in performance improvements of up to 23% in organic pollutant removal, while simultaneously extending filter life cycles by 15 to 20%. For companies where water reuse and environmental discharge compliance are priorities, the added value of premium carbon filtration—despite upfront price—is pronounced when considering operational risk management and brand protection.

Industrial users increasingly request custom filtration solutions tailored to unique processes, environmental goals, or spatial constraints. For example, automotive paint plants require not just standard filter panels, but also custom-sized primary and secondary filter stages, matched precisely to booth airflow characteristics and particulate spectra.

Leading suppliers offer modular and scalable filter arrays, integration with smart controls for differential pressure monitoring, and proprietary composite media designed for challenging aerosol and overspray profiles. Facility engineering teams now rate not only paint booth filter price but also integration support, delivery logistics, and post-installation monitoring. Custom service contracts, including predictive filter replacement schedules and on-site waste minimization programs, enable large plants to realize an additional 5–8% in annual operational savings.

In the water treatment arena, modular activated carbon canisters with easy-replacement cartridges allow for rapid exchange in high-usage areas, minimizing downtime and ensuring quality benchmarks are strictly maintained. Customization extends to advanced filtration skids and built-to-spec housing to accommodate complex fluid chemistries or spatial limitations.

Understanding and evaluating paint booth filter price alongside granular activated carbon filter costs is a decisive step for facilities committed to quality, compliance, and bottom-line savings. With regulatory scrutiny at an all-time high and ongoing advances in filter technology, buyers must consider not only initial outlay but also technical performance, longevity, integration, and certification. Data-driven comparisons reveal that high-efficiency and specialty filters often deliver lower total costs and enhanced process reliability.

Before finalizing procurement, end users should insist on verified test data, transparent pricing models, and robust post-sale technical support. Comprehensive vendor evaluation—anchored in performance metrics, case study evidence, and lifecycle cost analysis—ensures both operational excellence and strong returns on filtration investment across painting and water treatment lines.

(paint booth filter price)

Thickness:0.2-6 mm or Customized

Strand Thickness:0.5-8mm

Swd:2.5-100mm Lwd: 4.5-200mm

Surface Treatment:Powder Coated,Galvanized

MATERAL: PHENOLIC PAPER

MELT-BLOWN PBT

NON-WONEN LAMINATES

DIESEL FUEL FINE FILTERATION GRADE

APPLICATION : FUEL OIL WATER SEPERATION FILTER MEDIA

Material: Electrostatic cotton with activated carbon

PET/PP with Activated Carbon

Basic weight: 200-800g/m2

Application: Cabin Air Filters Panel Air Filters, Filter Cartridge, etc.

RAW MATERIAL: Polypropylene

PROCESS TECHNOLOGY: Melt-blown non-woven

RANGE OF EFFICIENCY: M5 ~ H11

Email to this supplier