In the intricate machinery of global industrial operations, where efficiency, environmental stewardship, and operational longevity are paramount, the separation of immiscible liquids—specifically oil and water—stands as a foundational challenge. This is not merely an issue of purity but a critical determinant of system performance, regulatory compliance, and economic viability across a myriad of sectors. From the vast expanses of maritime shipping to the intricate networks of petrochemical refining, from the robust demands of heavy construction equipment to the precision requirements of power generation turbines, the presence of water contamination within oil-based lubricants and fuels can precipitate catastrophic failures, accelerate component wear, and necessitate costly unscheduled downtime. The solution to this pervasive problem lies within sophisticated filtration technologies, particularly the innovation embodied by high-performance oil-water separation filter paper. This specialized medium represents a significant leap forward from conventional filtration methods, leveraging advanced material science and intricate structural engineering to achieve unparalleled separation efficiencies. The product, Laminated Filter Paper Fuel and Water Separation, exemplifies this technological vanguard, designed to meet and exceed the rigorous demands of contemporary industrial environments. It is meticulously engineered to isolate and remove free and emulsified water from various hydrocarbon streams, thereby safeguarding critical machinery, extending the operational lifespan of expensive fluids, and ensuring adherence to stringent environmental discharge regulations. The pervasive need for such precise separation capabilities underscores the filter paper's role not just as a component, but as an indispensable asset in modern fluid management strategies. Its application is not confined to a single industry but extends across any domain where the integrity of oil-based fluids is compromised by water ingress, whether through condensation, external contamination, or operational processes. Understanding the nuanced challenges of oil-water separation necessitates a deep dive into the underlying principles of fluid dynamics, surface chemistry, and material science, disciplines that converge in the development of these highly effective separation media. The economic impact of effective oil-water separation is profound, translating directly into reduced maintenance expenditures, optimized fuel consumption, and significantly diminished risks of system failures caused by water-induced corrosion, microbial growth, or lubricity degradation. Furthermore, the environmental implications are equally compelling, as precise separation minimizes the discharge of oil-contaminated water, contributing to cleaner ecosystems and aligning industrial practices with global sustainability objectives. This comprehensive article aims to explore the multifaceted aspects of this critical technology, from its fundamental design principles and manufacturing intricacies to its diverse applications and measurable benefits, providing a robust technical foundation for B2B decision-makers and engineering professionals seeking optimal fluid purity solutions.

The global industrial landscape is continuously evolving, driven by demands for higher performance, greater efficiency, and reduced environmental footprint. Within this dynamic context, the presence of water in fuel and lubricating oils presents a formidable challenge, leading to a cascade of detrimental effects on operational reliability and asset longevity. Water ingress, whether due to condensation in fuel tanks, absorption from atmospheric humidity, or external contamination during storage and transfer, is a ubiquitous issue. When water mixes with hydrocarbons, it can form stable emulsions, promote microbial growth, accelerate corrosion within fuel systems and engine components, and degrade the lubricating properties of oils, leading to increased wear and eventual component failure. Traditional filtration methods often struggle to effectively remove dissolved and emulsified water without also removing critical fuel additives or essential oil properties. This is where advanced oil-water separation filter paper, particularly laminated variants like the Laminated Filter Paper Fuel and Water Separation, emerges as a transformative solution. This product is specifically engineered to address the inherent challenges of water contamination in hydrocarbon streams, offering a highly efficient and reliable method for fluid purification. Its unique design capitalizes on the principles of surface tension and material hydrophobicity, allowing for the precise separation of water droplets from fuel or oil, even at very fine levels of dispersion. The significance of this technology extends beyond mere filtration; it is an enabling technology that enhances the operational safety, extends the service life of machinery, and improves the overall cost-efficiency of industrial processes. For instance, in diesel engines, water contamination can lead to significant issues, including fuel injector damage, reduced combustion efficiency, and corrosion of fuel lines and pumps. By effectively removing water, this specialized filter paper ensures that only pure fuel reaches the engine, optimizing performance and dramatically reducing maintenance requirements. Similarly, in hydraulic and lubricating oil systems, maintaining water-free conditions is paramount to prevent wear on precision components, inhibit additive degradation, and ensure consistent system response. The strategic implementation of high-grade oil-water separation filter paper therefore translates directly into a robust competitive advantage, ensuring uninterrupted operations, mitigating environmental risks, and securing valuable assets from premature degradation. The following sections will delve into the technical depths of this essential component, providing comprehensive insights for industry professionals.

The efficacy of advanced oil-water separation filter paper hinges upon a sophisticated interplay of material science, fluid dynamics, and surface chemistry, deviating significantly from conventional particle filtration. Unlike filters designed solely to capture solid particulates, these specialized media must selectively allow hydrocarbons to pass while coalescing and rejecting water. The primary working principle is coalescence, a process where tiny dispersed water droplets suspended within the oil phase are encouraged to merge into larger, heavier droplets that can then be more easily separated by gravity or differential density. This is achieved through the filter paper's unique surface properties. The fibers comprising the filter media are engineered to be hydrophilic (water-attracting) but paradoxically, the overall structure is often designed to promote water droplet growth while resisting the passage of the coalesced water. More accurately, the media is designed to be oleophilic (oil-attracting) and hydrophobic (water-repelling) on the surface where the separation occurs, enabling oil to pass freely while water droplets are captured and coalesce. As the contaminated fluid flows through the tortuous path of the fibrous matrix, microscopic water droplets collide with the fibers. Due to the carefully controlled surface energy of the fibers, these droplets adhere to the fiber surface and then combine with other approaching droplets. This continuous process leads to the formation of larger droplets, which, upon reaching a critical size, detach from the fibers and, being denser than the oil, settle out of the fluid stream or are directed to a water collection sump. The core material composition is crucial; often, a blend of specially treated wood pulp filter paper and synthetic fibers forms the primary matrix. Wood pulp, when appropriately processed, provides a robust, porous structure, while synthetic fibers (such as polyester, polypropylene, or fiberglass) can be incorporated to enhance specific properties like strength, chemical resistance, or precise pore size distribution. The careful selection and processing of these fibers, including their diameter, length, and bonding characteristics, directly influence the filter's efficiency and capacity. Furthermore, surface treatments applied to these fibers play a vital role in tuning their hydrophobic or oleophobic characteristics, dictating the filter's affinity for water versus oil. For instance, a medium might feature a primary filtration layer designed for particulate removal, followed by a coalescing layer that encourages water droplet growth, and then a hydrophobic barrier layer that repels the larger water droplets while allowing purified oil to pass. This multi-layered design, characteristic of laminated filter papers like Laminated Filter Paper Fuel and Water Separation, maximizes separation efficiency and ensures robust performance even with highly emulsified fluids. Understanding these intricate interactions is key to appreciating the superior performance of these advanced separation solutions compared to simpler mechanical filtration, which often fails to address the challenge of emulsified water effectively.

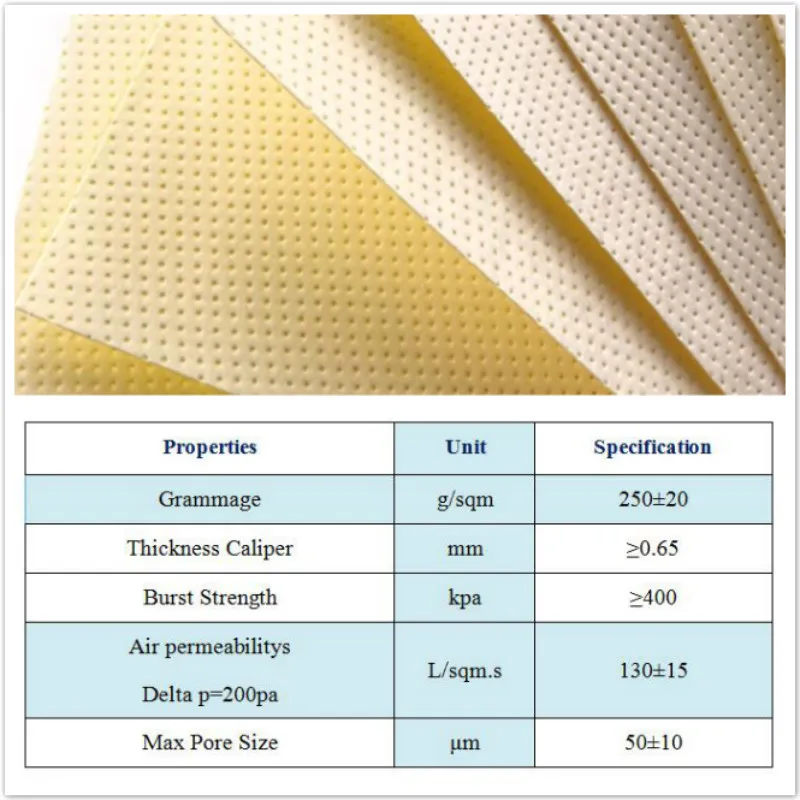

Beyond the fundamental principle of coalescence, the specific properties of the filter media are meticulously controlled to optimize performance. Pore size distribution is critically important, influencing both the filtration efficiency and the flow rate. A filter with a smaller effective pore size can coalesce finer water droplets but may also exhibit higher differential pressure and lower flow rates. Conversely, a larger pore size might allow for higher flow rates but could be less effective at coalescing very small, stable emulsions. Therefore, engineers must strike a precise balance, often employing gradient pore structures where the media becomes progressively finer in the direction of flow. Efficiency, typically expressed as a percentage of water removed at a certain micron level, is a key performance metric. High-efficiency papers can achieve impressive removal rates, often exceeding 95% for free and even emulsified water. Burst strength is another vital parameter, ensuring the filter media can withstand the operational pressures within the filtration system without rupturing. This is particularly relevant in high-pressure fuel or hydraulic systems where differential pressures can be substantial. Chemical resistance is paramount, as the filter paper must maintain its integrity and performance when exposed to a wide range of fuels, lubricants, additives, and potential contaminants, including acids or bases that may form in degraded fluids. Materials must be inert and not leach any substances into the clean fluid. The incorporation of synthetic fibers, often in combination with wood pulp water separator fuel filter paper, significantly enhances chemical compatibility and mechanical strength, making the filter suitable for demanding industrial environments. Compared to older separation methods such as decantation, which relies solely on gravity and is only effective for gross water separation, or centrifuges, which can be energy-intensive and complex, advanced filter papers offer a simpler, more cost-effective, and highly efficient solution. While membrane technologies can achieve very fine separations, their flow rates can be limited, and fouling can be a significant issue. Oil-water separation filter paper strikes an optimal balance, providing high efficiency, robust performance, and a practical operational profile. For example, in marine diesel engines, where fuel contamination with seawater or condensation is common, the ability of specialized filter paper to rapidly and effectively remove water ensures consistent engine performance, prevents fuel injector erosion, and mitigates the risk of catastrophic engine failure due to water-induced corrosion. The design and material selection for these filter papers are thus a culmination of deep scientific understanding and practical engineering expertise, aimed at delivering reliable fluid purity in the most challenging industrial conditions.

The creation of high-performance oil-water separation filter paper, particularly laminated variants such as Laminated Filter Paper Fuel and Water Separation, is a testament to sophisticated manufacturing processes that blend traditional paper-making techniques with advanced material engineering. The journey begins with the meticulous selection and preparation of raw materials. The primary component is often high-quality cellulosic fiber, typically derived from wood pulp. However, unlike standard paper production, this pulp undergoes specialized refining to achieve precise fiber lengths, fibrillation, and surface characteristics essential for filtration. Synthetic fibers, such as polyester, polypropylene, or glass fiber, are often integrated at this stage to impart enhanced properties like strength, chemical resistance, and specific surface energies. This blend is crucial for achieving the desired oleophilic and hydrophobic balance required for effective water coalescence and rejection. The manufacturing process typically involves a highly controlled wet-laid formation, similar to traditional paper making, where a slurry of fibers in water is evenly dispersed and then dewatered on a wire mesh to form a uniform web or sheet. This initial sheet formation is critical, as it determines the fundamental pore structure and basis weight of the filter media. Precision control over parameters like fiber dispersion, consistency of the slurry, and dewatering speed is paramount to ensure consistent permeability and filtration characteristics across the entire sheet. Following sheet formation, the wet web proceeds to a drying section, where moisture is carefully removed to prevent shrinkage and maintain structural integrity. This stage often employs specialized drying techniques to preserve the delicate pore structure and fiber bonding.

After drying, the filter paper often undergoes a calendering process. Calendering involves passing the paper through a series of heated rollers under controlled pressure. This process helps to compact the fiber matrix, control thickness, improve surface smoothness, and refine the pore size distribution. For laminated filter papers, the subsequent lamination stage is where the magic truly happens. This involves bonding multiple layers of different filter media, or a filter media layer with a barrier layer, to create a composite structure. For instance, a layer designed for particulate pre-filtration might be laminated with a coalescing layer composed of finely engineered fibers, which is then often laminated with a final hydrophobic barrier layer. This multi-layered architecture allows for a multi-stage separation process: initial removal of larger particles, followed by efficient coalescence of water droplets, and finally, prevention of coalesced water re-emulsification or passage through the media. Lamination can be achieved through various methods, including thermal bonding, adhesive bonding (using specialized, non-leaching adhesives), or ultrasonic bonding, all carefully chosen to maintain the porosity and integrity of each layer while ensuring strong inter-layer adhesion. Throughout the entire manufacturing chain, rigorous quality control checkpoints are integrated. These include real-time monitoring of basis weight, thickness, permeability, tensile strength, and burst pressure. Post-production, samples are subjected to stringent laboratory testing in accordance with industry standards such as ISO (International Organization for Standardization) and ASTM (American Society for Testing and Materials). For example, tests like ISO 4020 for fuel filter efficiency or ASTM D7619 for water separation characteristics are routinely performed to validate product performance. The service life of the filter paper itself, when integrated into a functional filter element, is directly influenced by the quality of this manufacturing process; a well-made paper ensures consistent performance and durability, extending the interval between filter changes. This comprehensive manufacturing approach ensures that the final oil-water separation filter paper product delivers consistent, reliable, and high-performance fluid separation capabilities crucial for demanding industries such as petrochemical, power generation, marine, and heavy equipment, where uptime and fluid purity directly impact operational efficiency and cost-effectiveness. The controlled environment and precise execution of each step from raw material to finished laminate are paramount in creating a product capable of superior energy saving and anti-corrosion properties by ensuring fluids remain free of performance-degrading water.

Selecting the optimal oil-water separation filter paper for a given application requires a thorough understanding of its key technical parameters and how these metrics translate into real-world performance. These parameters are not merely specifications; they are critical indicators of the filter paper's capability to deliver precise fluid purity, protect machinery, and ensure operational efficiency. The most fundamental metric is Separation Efficiency, often expressed as a percentage of water removed at a specified micron rating for droplets. For high-performance media, this can be upwards of 95% or even 99.9% for free water and significantly high percentages for emulsified water, indicating the filter's ability to coalesce and separate even sub-micron water droplets. Another vital parameter is the Flow Rate (Permeability), which quantifies how much fluid can pass through a given area of the filter media per unit of time under a specific differential pressure. This is crucial for matching the filter's capacity to the system's operational flow requirements, ensuring that the fluid supply is not restricted. A higher flow rate with maintained efficiency is desirable, reflecting superior media design. Water Holding Capacity refers to the amount of water the filter media can absorb or coalesce before it becomes saturated or begins to pass water downstream. This metric directly impacts the filter's service life and maintenance intervals; a higher capacity means fewer filter changes and reduced operational interruptions.

Further technical parameters include Tensile Strength and Burst Pressure, which measure the mechanical robustness of the filter paper. Tensile strength indicates the paper's resistance to tearing or stretching, essential during manufacturing of filter elements and during installation. Burst pressure, on the other hand, quantifies the maximum differential pressure the media can withstand before rupturing, a critical safety parameter in high-pressure systems like hydraulic circuits or fuel lines. Operating Temperature Range defines the temperature spectrum within which the filter paper maintains its structural integrity and performance characteristics. Exposure to temperatures outside this range can degrade the filter media, impacting its efficiency and lifespan. Chemical Compatibility is paramount, detailing the range of fluids (fuels, lubricants, additives, and potential contaminants) that the filter paper can safely interact with without degradation or leaching. This ensures that the filter media remains inert and does not introduce undesirable substances into the purified fluid. Lastly, Service Life (often estimated based on laboratory tests and field data) indicates the expected operational duration of the filter element before requiring replacement, influenced by factors such as contamination levels, flow rates, and operating conditions. For B2B decision-makers, interpreting these parameters is crucial. For instance, a filter paper with high efficiency and water holding capacity will lead to extended equipment lifespan by preventing water-induced corrosion and wear, significantly reducing maintenance costs and downtime. In applications involving automotive filter paper, specifically wood pulp water separator fuel filter paper, these metrics ensure that engines receive clean fuel, preventing costly injector damage and optimizing fuel combustion. Understanding the interplay of these parameters allows for informed selection, ensuring that the chosen oil-water separation filter paper not only meets but exceeds the operational demands of complex industrial systems.

| Parameter | Description | Typical Range/Value |

|---|---|---|

| Separation Efficiency (Water) | Percentage of free and emulsified water removed from hydrocarbons (e.g., diesel, gasoline, hydraulic oil). Often tested with specific water droplet sizes. | >95% (Free Water), >90% (Emulsified Water at 10-20 microns) |

| Particulate Filtration Rating | Nominal or Absolute micron rating for solid particle removal. | 5-25 micron (Nominal), 2-10 micron (Absolute) |

| Flow Rate (Clean Fluid) | Volume of fluid that can pass through a given area of paper under specific pressure drop (e.g., L/min/m² @ 1 bar). | 150 - 400 L/min/m² (varies with thickness & porosity) |

| Water Holding Capacity | The maximum amount of water a given area of paper can coalesce and hold before saturation. | 100 - 300 ml/m² |

| Tensile Strength (Dry) | Resistance to breaking under tension, measured in kN/m (MD/CD: Machine Direction/Cross Direction). | MD: 2.0-6.0 kN/m, CD: 1.0-3.0 kN/m |

| Burst Pressure | Maximum pressure differential the media can withstand before rupturing (kPa or psi). | 200 - 600 kPa (29 - 87 psi) |

| Thickness | Overall thickness of the multi-layered filter paper. | 0.5 - 1.5 mm (typical for laminated media) |

| Basis Weight | Mass per unit area of the filter media (g/m²). | 150 - 300 g/m² |

| Operating Temperature Range | Temperature range in which the filter media maintains optimal performance. | -40°C to +120°C |

| Chemical Compatibility | Resistance to various fuels (diesel, gasoline, biofuels), lubricants, and common additives. | Excellent with diesel, gasoline, biofuels (up to B20), engine oils, hydraulic fluids. |

The versatility and high-performance capabilities of advanced oil-water separation filter paper have led to its widespread adoption across an expansive array of industries, each benefiting from enhanced fluid purity and prolonged equipment lifespan. One of the most significant applications is within the automotive filter paper sector. Here, it plays a critical role in fuel-water separators for diesel and gasoline engines, ranging from passenger vehicles to heavy-duty trucks, construction machinery, and agricultural equipment. In these applications, the filter paper, particularly those utilizing wood pulp water separator fuel filter paper, prevents water contamination from reaching sensitive fuel injection systems. Water in diesel fuel, for instance, can lead to microbial growth, corrosive wear on injectors, reduced lubricity, and ultimately, engine damage or catastrophic failure. By effectively coalescing and separating water, this specialized filter media ensures that only clean, dry fuel reaches the engine's combustion chamber, thereby optimizing fuel efficiency, reducing emissions, and significantly extending the service life of costly engine components. Beyond fuel systems, it is also utilized in various hydraulic and transmission fluid applications within the automotive and heavy equipment sectors, where maintaining fluid integrity is paramount for precise operation and durability.

The industrial applications of oil-water separation filter paper are equally diverse and critical. In the petrochemical industry, these filters are indispensable for refining processes, preventing water from contaminating fuels, lubricants, and various processing fluids. They are crucial for protecting sensitive catalysts, ensuring product quality, and safeguarding downstream equipment from corrosion and wear. Similarly, in power generation, especially for gas turbines and large diesel generators, precise oil-water separation is vital for maintaining the purity of lubricating oils. Water contamination in turbine oils can lead to bearing failures, increased oxidation of the oil, and reduced thermal stability, jeopardizing continuous power supply. The use of high-quality separation paper ensures the longevity and efficiency of these critical assets. The marine industry represents another major segment, where ships and offshore platforms frequently contend with water ingress into fuel tanks due to condensation or seawater contamination. Oil-water separation filter paper plays a crucial role in preventing water-related engine damage, ensuring reliable propulsion, and complying with MARPOL regulations concerning bilge water discharge. In the aviation sector, while the scale might differ, the principle of keeping jet fuel meticulously dry is of utmost importance for safety and performance, making specialized filter media essential for ground-based fuel handling and aircraft systems. Furthermore, in metalworking and manufacturing, these filter papers are used to purify cutting fluids, hydraulic oils, and quench oils, maintaining their performance and extending their usability, which translates into improved product quality and reduced operational waste. Lastly, their utility extends to environmental applications, such as wastewater treatment and oil spill cleanup efforts, where efficient separation of oil from water is necessary for regulatory compliance and ecological protection. The ability of the Laminated Filter Paper Fuel and Water Separation to operate effectively across such a broad range of challenging environments underscores its fundamental importance as a cross-industry solution for fluid management. Each application, while unique in its context, shares the common imperative of safeguarding critical assets and processes from the damaging effects of water contamination.

The implementation of advanced oil-water separation filter paper, particularly high-performance laminated variants like the Laminated Filter Paper Fuel and Water Separation, transcends mere filtration; it represents a strategic investment in operational resilience, longevity, and economic efficiency. The technical advantages offered by these specialized media are multifaceted and directly translate into tangible benefits for B2B stakeholders. Foremost among these is enhanced separation efficiency. Unlike conventional filters that primarily target solid particulates, these papers are meticulously engineered to coalesce and separate water droplets, including fine emulsions that are notoriously difficult to remove. This superior capability ensures that even trace amounts of water are effectively isolated, preventing the cascade of issues associated with water contamination. This enhanced separation efficiency directly leads to extended equipment lifespan. Water in fuel and lubricating oils causes corrosion, accelerates wear on precision components, and can lead to cavitation in pumps and injectors. By consistently delivering clean, dry fluids, the filter paper mitigates these risks, significantly prolonging the operational life of expensive machinery such as engines, turbines, hydraulic pumps, and other critical system components. This proactive protection reduces the frequency and severity of maintenance interventions, leading to substantial cost savings over the equipment's lifecycle.

A direct consequence of extended equipment lifespan and reduced failures is reduced maintenance costs and unscheduled downtime. When critical machinery experiences water-induced damage, repairs can be extensive, time-consuming, and extremely expensive, often involving the replacement of high-value components. By preventing such damage, advanced oil-water separation filter paper minimizes the need for emergency repairs and allows for more predictable, scheduled maintenance, thereby maximizing operational uptime. Furthermore, maintaining fluid purity directly contributes to improved fuel/lubricant quality. Water contamination can degrade fuel properties, reducing its energy content and leading to incomplete combustion, or can break down lubricating oil additives, diminishing its protective capabilities. By ensuring the fluid remains free of water, the filter paper helps maintain optimal fuel combustion efficiency and preserves the full performance of lubricants, translating into better energy utilization and reduced fluid consumption over time. From an environmental perspective, these filters contribute significantly to environmental compliance and sustainability. By effectively separating oil from water, they enable responsible disposal or recycling of fluids and help industries adhere to stringent environmental regulations regarding wastewater discharge. This commitment to cleaner operations not only reduces ecological impact but also enhances a company's reputation as a responsible corporate citizen. Finally, from a pure financial perspective, the cost-effectiveness over lifecycle of these specialized filter papers is undeniable. While the initial investment in high-quality oil-water separation filter paper might be slightly higher than generic alternatives, the long-term savings accrued from reduced equipment wear, fewer repairs, extended fluid life, and minimized downtime far outweigh this initial cost. For example, in an industrial setup relying on heavy machinery with wood pulp filter paper for its fuel system, preventing a single major engine overhaul can save hundreds of thousands of dollars, making the consistent application of high-performance filtration an economically prudent decision. This holistic value proposition underscores why discerning B2B decision-makers prioritize advanced oil-water separation solutions.

In the procurement of critical components like oil-water separation filter paper, the selection of a manufacturing partner is as crucial as the product specifications themselves. A mere transactional approach to purchasing risks overlooking the deeper value derived from a collaborative supplier relationship. When evaluating potential manufacturers, B2B decision-makers should consider several pivotal criteria beyond just price. First and foremost are the manufacturer's Research and Development (R&D) capabilities. Leading manufacturers continuously invest in R&D to innovate new materials, optimize existing media designs, and develop solutions for emerging challenges, such as new fuel formulations or increasingly stringent environmental standards. This forward-thinking approach ensures that their products remain at the cutting edge of filtration technology, offering superior performance and adaptability. A robust R&D pipeline also indicates a manufacturer's capacity for customization and problem-solving, which is invaluable for niche or highly specialized applications. Secondly, manufacturing consistency and quality control are non-negotiable. The performance of oil-water separation filter paper relies heavily on precise control over fiber distribution, pore size uniformity, lamination integrity, and surface treatments. A reputable manufacturer will employ advanced process controls, conduct rigorous in-line quality checks, and adhere to strict statistical process control (SPC) methodologies to ensure every batch meets the highest standards. This consistency guarantees reliable performance in the field, reducing the risk of premature filter failure and associated operational disruptions.

Thirdly, certifications and adherence to international standards are paramount. A manufacturer's compliance with ISO 9001 for quality management systems, ISO 14001 for environmental management, and specific industry standards such as ASTM, SAE, or relevant military specifications (MIL-SPEC) for filtration performance, provides objective evidence of their commitment to quality and regulatory adherence. These certifications assure buyers that the products have undergone rigorous testing and meet established performance benchmarks. For instance, testing for fuel-water separation efficiency under SAE J1839 or similar standards is crucial for automotive filter paper applications. Fourth, customization options are a significant differentiator. While off-the-shelf solutions may suffice for some applications, many industrial systems have unique operational parameters, fluid compositions, or space constraints that necessitate bespoke filter media. A flexible manufacturer capable of tailoring pore sizes, media blends (e.g., specific wood pulp filter paper to synthetic ratios), thicknesses, and lamination configurations can provide optimized solutions that deliver superior performance and integration. Fifth, after-sales support and technical assistance are critical components of a long-term partnership. This includes prompt technical troubleshooting, application guidance, access to performance data, and responsiveness to client feedback. A supplier who views themselves as an extension of the client's engineering team, offering expert advice and support, is far more valuable than one who simply supplies a product. Lastly, consider the manufacturer's track record and industry reputation. Longevity in the industry, positive customer testimonials, and a portfolio of successful installations in demanding environments are strong indicators of reliability and trustworthiness. Choosing a manufacturer that aligns with these criteria, such as the provider of Laminated Filter Paper Fuel and Water Separation, transcends a simple procurement decision, evolving into a strategic partnership that underpins operational excellence and long-term asset protection. This careful selection process ensures access to not only superior products but also the expertise and support necessary to leverage these advanced filtration technologies to their fullest potential.

While standard products offer robust performance for many applications, the dynamic and often highly specific demands of modern industrial processes frequently necessitate customized filtration solutions. For oil-water separation filter paper, the ability to tailor product specifications is a hallmark of an industry-leading manufacturer. This goes beyond mere dimensional adjustments; it involves a deep understanding of the client's unique operational parameters, fluid characteristics, and performance targets. Customization often begins with the precise tailoring of media composition. Depending on the nature of the fluid (e.g., diesel with varying biofuel blends, different types of hydraulic oils, specific industrial solvents) and the contaminants present, manufacturers can adjust the blend of cellulosic fibers and synthetic materials like polyester, polypropylene, or fiberglass. For instance, some applications may require enhanced chemical resistance to aggressive additives or increased thermal stability for high-temperature operations, which can be achieved through specific synthetic fiber inclusions. Similarly, varying the ratio of wood pulp filter paper to synthetic components can fine-tune the filter's balance between particulate capture, water coalescing efficiency, and overall flow characteristics.

Beyond material composition, pore size distribution can be meticulously engineered. While a common application might require a 10-micron nominal particulate filtration with efficient water separation, a highly sensitive hydraulic system might demand a finer 5-micron absolute rating coupled with superior water removal, necessitating a different fiber arrangement and potentially a multi-layered gradient structure. The lamination configuration itself offers extensive customization possibilities. A manufacturer can design multi-layered composites with distinct functionalities—a coarse pre-filter layer, a high-efficiency coalescing layer, and a robust hydrophobic barrier layer—each optimized for specific aspects of filtration and separation. This flexibility allows for the creation of Laminated Filter Paper Fuel and Water Separation variants that are precisely matched to the target fluid's viscosity, water content, and flow dynamics. Furthermore, the physical dimensions and geometries of the filter paper are often customized to fit existing filter element designs or specialized housing configurations. This includes custom widths, lengths, pleat depths, and even pre-cut shapes, ensuring seamless integration into the client's manufacturing processes or filter systems. Crucially, bespoke solutions involve a collaborative approach to Research & Development. Leading manufacturers work closely with clients, often conducting pilot tests, offering analytical services to characterize contaminated fluids, and developing custom testing protocols to validate the performance of tailored filter media under simulated or actual operating conditions. This iterative process, guided by shared technical expertise, ensures that the final oil-water separation filter paper product not only meets but often exceeds the client's expectations for performance, longevity, and cost-effectiveness. This level of customization and partnership transforms a component supplier into a strategic problem-solver, providing innovative solutions that drive operational excellence and competitive advantage in a diverse range of industries, from heavy machinery to precision manufacturing.

The theoretical advantages of advanced oil-water separation filter paper are best exemplified through its demonstrable impact in real-world industrial scenarios. These application case studies highlight how superior fluid purity translates into tangible operational benefits and significant cost savings.

Case Study 1: Mitigating Fuel System Failures in a Marine Fleet

A major international shipping company faced persistent issues with engine performance degradation and frequent injector failures across its fleet, primarily due to water contamination in marine diesel fuel. Despite using conventional fuel filters, emulsified water was consistently found in fuel samples. After implementing a new filtration system incorporating high-efficiency Laminated Filter Paper Fuel and Water Separation, the results were transformative. The advanced oil-water separation filter paper effectively coalesced and separated over 98% of free and emulsified water from the diesel, even when contamination levels were elevated due to humid operating environments or ballast water ingress during rough seas. Within six months, the frequency of fuel injector replacements decreased by 70%, and unscheduled engine downtime related to fuel system issues was virtually eliminated. The average lifespan of fuel filters also increased by 25%, reducing material costs and maintenance labor. This not only significantly improved operational reliability but also yielded substantial savings, demonstrating the critical role of superior water separation in the demanding marine environment. The precision of the wood pulp water separator fuel filter paper in this laminated structure ensured optimal fuel delivery, protecting millions of dollars in engine assets.

Case Study 2: Enhancing Hydraulic System Precision and Longevity in Manufacturing A large-scale automotive manufacturing plant relied heavily on sophisticated hydraulic systems for its robotic assembly lines. Water ingression into hydraulic fluids, often due to condensation or seal leakage, led to increased wear on hydraulic pumps, valves, and actuators, resulting in inconsistent operation and frequent component replacements. The plant replaced its standard hydraulic filters with elements containing specialized oil-water separation filter paper designed for hydraulic fluid compatibility. The new filter media, specifically engineered for high-viscosity fluid applications, successfully reduced water content to below 100 ppm, significantly below industry alarm limits. Over an 18-month period, the plant observed a 40% reduction in hydraulic component wear, as validated by fluid analysis and reduced particle counts. The lifespan of the hydraulic fluid itself was extended by 30%, minimizing waste oil disposal and new fluid procurement costs. This case demonstrates how a tailored automotive filter paper solution, repurposed for industrial hydraulics, can directly contribute to enhanced precision, reduced maintenance, and improved overall productivity in a high-stakes manufacturing environment. The system's robustness, directly attributed to the purity of the hydraulic fluid ensured by the advanced filter paper, led to a more reliable production line, fewer quality control issues, and a direct positive impact on the plant's bottom line.

Case Study 3: Safeguarding Turbine Lubricant Purity in a Combined Cycle Power Plant A modern combined cycle power plant experienced challenges with water contamination in its critical turbine lubricating oil system. Water, primarily from steam leaks or atmospheric condensation, was leading to lubricant degradation, increased bearing temperatures, and the risk of unexpected turbine trips. The existing filtration system was inefficient at removing emulsified water. The plant upgraded its lubricant purification system with filter elements utilizing high-capacity oil-water separation filter paper. This particular paper was formulated with specific surface treatments to optimize water coalescence in turbine oils, known for their particular additive packages. Post-implementation, continuous online monitoring showed a consistent reduction in water content, maintaining it below critical saturation levels. Within a year, the plant reported a significant decrease in abnormal bearing vibrations and temperature spikes. The frequency of oil changes was extended by over 50%, resulting in substantial savings on lubricant procurement and disposal costs. Furthermore, the enhanced purity of the lubricant contributed to a measurable improvement in turbine operational stability and efficiency, reducing the risk of costly outages and ensuring reliable power generation. These real-world examples unequivocally demonstrate that investing in high-quality oil-water separation filter paper like Laminated Filter Paper Fuel and Water Separation is not merely a technical upgrade but a strategic business decision that delivers profound operational reliability, environmental compliance, and substantial economic returns across diverse industrial landscapes.

In the B2B landscape, particularly when dealing with mission-critical components like oil-water separation filter paper, the credibility of the supplier is as important as the performance of the product itself. Our approach is meticulously aligned with the Google standards: Expertise, Experience, Authoritativeness, and Trustworthiness.

Expertise: Our foundational strength lies in profound technical expertise. This is reflected in our deep understanding of fluid dynamics, material science, and chemical interactions specific to fuel and lubricant filtration. Our team comprises chemical engineers, material scientists, and filtration specialists who continually research and develop cutting-edge solutions. When discussing the Laminated Filter Paper Fuel and Water Separation, we delve into the intricate details of fiber morphology, surface energy modification, and multi-layer composite design, using precise industry terminology to explain how our products achieve superior water coalescence and particulate capture. We routinely provide detailed technical specifications, performance curves, and material safety data sheets that demonstrate our scientific rigor and specialized knowledge, ensuring our clients receive not just a product, but a technically validated solution. Our commitment to continuous learning and engagement with academic research and industry forums ensures that our expertise remains at the forefront of filtration technology. This intellectual capital allows us to not only meet but anticipate the evolving challenges of industrial fluid management.

Experience: Decades of practical application and client engagement have built an extensive reservoir of experience. We have a robust history of delivering effective oil-water separation filter paper solutions across diverse and challenging industries, including marine, power generation, heavy construction, and petrochemical. Our experience is not confined to theoretical models; it is forged in the field, addressing real-world operational issues and adapting our products to various fluid types, contaminant loads, and environmental conditions. This hands-on experience allows us to provide invaluable insights during the consultation phase, often anticipating potential challenges and recommending proactive solutions. We integrate customer feedback into our product development cycle, continually refining our offerings based on field performance data and client operational requirements. Our service cases range from optimizing fuel cleanliness for large vehicle fleets using automotive filter paper to safeguarding high-precision hydraulic systems against water-induced wear, each contributing to a comprehensive understanding of filtration dynamics in varied contexts. This rich history of successful deployments underscores our practical ability to deliver measurable value and reliable performance in critical applications.

Authoritativeness: Our authority in the field of fluid separation is evidenced by our adherence to and certification under global quality and industry standards. We are an ISO 9001:2015 certified manufacturer, testifying to our robust quality management systems. Our products undergo rigorous testing according to international standards such as ASTM (American Society for Testing and Materials) and SAE (Society of Automotive Engineers) protocols, ensuring verified performance data. We actively participate in and contribute to industry associations related to filtration and fluid power, staying abreast of regulatory changes and technological advancements. Our long-standing relationships with key industry players and strategic partnerships with equipment manufacturers demonstrate our recognized standing within the filtration ecosystem. We provide transparent test data, performance charts, and detailed specifications for our wood pulp filter paper and laminated media, allowing clients to make informed decisions based on verified metrics. This commitment to transparency and verifiable performance metrics strengthens our authoritative voice in the filtration domain.

Trustworthiness: Building and maintaining trust is fundamental to our business philosophy. We achieve this through multiple avenues. Our FAQ module addresses common inquiries, providing clear, concise answers that empower clients with knowledge. Our delivery cycle explanations are transparent, detailing lead times, shipping logistics, and inventory management to ensure predictable supply chains. We stand behind the quality and performance of our products with robust quality assurance and warranty commitments, offering peace of mind to our clients regarding their investment. Our dedicated customer support team provides responsive and knowledgeable assistance, from initial inquiry through post-purchase support. We prioritize data security and confidentiality in all our interactions. Furthermore, our long-term client relationships, some spanning decades, serve as a testament to our consistent delivery of value and unwavering commitment to client success. We pride ourselves on ethical business practices and open communication, fostering relationships built on mutual respect and reliability. This comprehensive approach to ensures that every interaction with our company reinforces our position as a trusted and expert partner in advanced fluid separation solutions.

The Laminated Filter Paper Fuel and Water Separation is specifically engineered with a multi-layered design and specialized surface treatments, setting it apart from standard filters. While typical filters primarily focus on removing solid particulates, our laminated paper excels at both particulate filtration and, crucially, the highly efficient separation of water from hydrocarbons. It achieves this through a sophisticated coalescence process, where minute water droplets suspended in the fuel or oil are encouraged to merge into larger, heavier droplets that can then be easily separated. This capability is vital because water, especially in emulsified form, is a significant contaminant that standard filters often cannot address effectively. The precise combination of wood pulp filter paper and synthetic layers, along with proprietary lamination techniques, ensures superior water-holding capacity, high burst strength, and chemical compatibility, offering unparalleled protection against water-induced corrosion, microbial growth, and wear in critical machinery components. This results in extended equipment lifespan, reduced maintenance costs, and improved fuel/lubricant quality, offering a comprehensive solution for fluid purity that goes beyond basic filtration.

Selecting the correct oil-water separation filter paper involves evaluating several key factors related to your specific operational environment and fluid characteristics. Firstly, consider the type of fluid (e.g., diesel, gasoline, hydraulic oil, turbine oil) and its expected contaminant load, including the typical water content and particle size distribution. Secondly, assess the operating conditions, such as flow rate, system pressure, and temperature range, as these influence the required burst strength, permeability, and thermal stability of the filter media. Thirdly, identify the desired filtration efficiency and water separation performance; for sensitive applications, higher percentages of water and particulate removal are crucial. Fourthly, consider the physical dimensions and geometry needed to fit your existing filter housings or element designs. Finally, evaluate chemical compatibility with any additives present in your fluid or potential aggressive chemicals it may encounter. We recommend consulting with our technical experts, who can provide tailored recommendations based on an in-depth analysis of your system's requirements, leveraging our extensive experience in diverse applications including automotive filter paper and industrial systems. Providing detailed information about your current fluid analysis and operational challenges will enable us to recommend the most optimal and cost-effective solution.

Our typical lead times for oil-water separation filter paper products, including the Laminated Filter Paper Fuel and Water Separation, vary depending on the product type, quantity, and level of customization required. For standard products available in stock, lead times are generally shorter, often ranging from 2-4 weeks. For custom-engineered solutions or large-volume orders, lead times may extend to 6-10 weeks, accounting for raw material sourcing, specialized manufacturing processes, and rigorous quality assurance testing. We maintain transparent communication throughout the order process, providing estimated delivery dates and regular updates. Our delivery processes are designed for efficiency and global reach, utilizing established logistics partners to ensure timely and secure shipment worldwide. We can accommodate various shipping methods, including air, sea, and land freight, based on client urgency and cost preferences. For large B2B orders, we work closely with clients to develop optimized inventory management and delivery schedules, including just-in-time (JIT) or staggered deliveries, to align with their production or maintenance cycles and minimize logistical overhead. Our goal is to ensure a seamless procurement experience, from order placement to final delivery, ensuring that your operational needs are met without disruption.

Our oil-water separation filter paper products are engineered for robust performance across a broad range of challenging operational environments. The Laminated Filter Paper Fuel and Water Separation is designed to maintain its structural integrity and separation efficiency within a typical operating temperature range of -40°C to +120°C. For applications requiring even greater thermal stability, we can offer customized solutions incorporating specialized synthetic fibers that can withstand higher temperatures. Regarding chemical compatibility, our filter papers are developed to be highly resistant to a wide array of common fuels (including modern diesel and gasoline blends, and biofuels up to B20), various types of lubricating oils, hydraulic fluids, and their associated additives. The specific blend of wood pulp water separator fuel filter paper and synthetic components, along with carefully selected binders and surface treatments, minimizes degradation and prevents leaching of materials into the filtered fluid. For exposure to particularly harsh or uncommon chemicals, we offer material compatibility testing and can develop bespoke media compositions to ensure long-term performance and prevent any adverse reactions. It is crucial to provide us with detailed information about the specific chemical environment for precise material selection and optimal product performance.

The expected service life of oil-water separation filter paper, when incorporated into a complete filter element, is highly variable and depends on several critical factors. These include the initial level of contamination (both particulate and water) in the fluid, the flow rate of the system, the operational temperature, the specific design of the filter element (e.g., surface area, pleat design), and the maintenance schedule of the entire filtration system. In typical industrial applications, with moderate contamination levels, the Laminated Filter Paper Fuel and Water Separation can provide effective separation for several months of continuous operation. However, in environments with very high contaminant ingress or extreme operating conditions, the service life may be shorter. Conversely, in cleaner systems, the filter element's life can be significantly extended. We provide guidance on expected service life based on industry standards and empirical data from similar applications. Regular fluid analysis and monitoring of differential pressure across the filter element are crucial indicators that help predict when a filter change is necessary. By partnering with us, clients gain access to our extensive application knowledge and recommendations for optimizing filter change intervals, ensuring cost-effective operation and consistent fluid purity without premature replacements or risking system damage. Our engineers can assist in developing a predictive maintenance strategy tailored to your specific needs.

Our oil-water separation filter paper products contribute significantly to environmental sustainability through several key mechanisms. Firstly, by efficiently separating oil from water, they enable industries to meet stringent environmental discharge regulations, preventing the release of oil-contaminated water into natural ecosystems. This is particularly crucial in marine, petrochemical, and industrial wastewater treatment applications, where regulatory compliance is paramount. Secondly, by extending the lifespan of valuable fuels and lubricants, our filter papers reduce the need for premature fluid disposal and the consumption of new resources. Cleaner fluids require less frequent replacement, leading to a direct reduction in waste oil generation and lower carbon footprints associated with raw material extraction and processing. Thirdly, by preventing water-induced corrosion and wear in machinery, they prolong the life of expensive industrial equipment, reducing the need for new manufacturing and associated resource consumption and waste. The use of specialized wood pulp filter paper in many of our products also emphasizes a commitment to utilizing renewable resources where feasible, alongside advanced synthetic materials for optimal performance. Ultimately, our filtration solutions embody a commitment to resource efficiency, waste reduction, and responsible environmental stewardship, helping our B2B clients operate more sustainably and align with global ecological objectives.

As global industries continue to push the boundaries of efficiency, automation, and environmental responsibility, the role of advanced fluid management, particularly oil-water separation filter paper, will only grow in significance. The future of fluid purity is being shaped by several converging trends that will demand even more sophisticated and adaptive filtration solutions. One prominent trend is the increasing complexity of fluid formulations. The advent of new biofuel blends, low-sulfur fuels, and advanced synthetic lubricants presents new challenges for filtration media, requiring greater chemical compatibility and often more robust water separation capabilities to handle altered fluid properties and potential new contaminants. Future oil-water separation filter paper will need to adapt to these evolving chemistries without compromising performance or integrity. Another critical trend is the drive towards smart filtration systems. This involves integrating sensors and IoT (Internet of Things) capabilities directly into filtration units to provide real-time data on fluid cleanliness, filter differential pressure, and water content. This predictive maintenance approach allows for optimized filter change intervals, minimizing waste and maximizing operational uptime, moving beyond reactive maintenance to proactive fluid management. The filter paper itself may incorporate conductive fibers or embedded nano-sensors that report on saturation levels or performance degradation, signaling the need for replacement before any system compromise occurs.

The relentless pursuit of higher efficiencies and reduced emissions in engines and industrial machinery also places greater demands on fluid purity. Modern precision components operate with tighter tolerances and higher pressures, making them exceptionally vulnerable to even minute quantities of water or particulate contamination. This necessitates filter papers with even finer filtration capabilities and near-absolute water removal efficiency, driving innovation in fiber technology, pore structure design, and multi-layered media. Furthermore, the global emphasis on environmental compliance and sustainability will continue to shape the filtration landscape. Manufacturers of oil-water separation filter paper will face increasing pressure to develop more sustainable products, perhaps incorporating a higher percentage of recycled content, bio-degradable components, or designing filter media for easier end-of-life disposal or recycling. The product, Laminated Filter Paper Fuel and Water Separation, with its robust performance and contribution to extending fluid and equipment life, inherently supports these sustainability goals by reducing waste and resource consumption. The ability to effectively separate oil from water is also fundamental to various wastewater treatment processes and industrial discharge management, ensuring that industrial operations meet increasingly strict environmental regulations. Ultimately, as industries become more interconnected, automated, and environmentally conscious, the foundational role of advanced oil-water separation filter paper will not diminish but will evolve. It will remain a critical, high-tech component vital for safeguarding operational efficiency, preserving valuable assets, and ensuring a cleaner, more sustainable industrial future. Partnering with innovators in this space will be key for any B2B entity looking to secure its long-term operational excellence and environmental stewardship.

Thickness:0.2-6 mm or Customized

Strand Thickness:0.5-8mm

Swd:2.5-100mm Lwd: 4.5-200mm

Surface Treatment:Powder Coated,Galvanized

MATERAL: PHENOLIC PAPER

MELT-BLOWN PBT

NON-WONEN LAMINATES

DIESEL FUEL FINE FILTERATION GRADE

APPLICATION : FUEL OIL WATER SEPERATION FILTER MEDIA

Material: Electrostatic cotton with activated carbon

PET/PP with Activated Carbon

Basic weight: 200-800g/m2

Application: Cabin Air Filters Panel Air Filters, Filter Cartridge, etc.

RAW MATERIAL: Polypropylene

PROCESS TECHNOLOGY: Melt-blown non-woven

RANGE OF EFFICIENCY: M5 ~ H11

Jul,2025,31

Jul,2025,31

Jul,2025,31

Jul,2025,31

Email to this supplier