In today's rapidly evolving industrial and domestic filtration landscape, activated carbon filter for sale solutions have become indispensable. These filters, renowned for exceptional contaminant removal, are engineered using superior activated carbon filter media. Their applications span water purification, air quality enhancement, industrial gas processing, and beyond. As global regulatory and consumer demands tighten, the search for reliable activated carbon filter suppliers and high-efficiency filter media intensifies, making product selection a critical business function.

According to Water Quality Association (WQA), activated carbon remains a preferred filtration approach due to its adaptability to multiple contaminants and broad compatibility across industries. The global carbon filter media market is forecasted to reach USD 5.8 billion by 2028 (MarketsandMarkets).

With decades of expertise and innovation, Hebei Fangyu Filters Material Technology Co,. Ltd. stands as a premier manufacturer and exporter of activated carbon filter for sale solutions. As a recognized authority, we serve OEM, industrial, and aftermarket clients worldwide, providing a full spectrum of carbon filter media and advanced composite solutions that meet international quality and safety standards.

Our activated carbon filter for sale combines high adsorption efficiency with advanced composite technology, suited for removing VOCs, odors, particulates, chlorine, and various industrial pollutants. The unique blend of PET/PP substrates and electrostatic properties delivers robust structural integrity and extended filter lifespan.

The surge in environmental protection policies, together with smart automation and IoT integration, has accelerated the innovation of activated carbon filters. Growing demands from automotive, pharmaceuticals, water treatment, and electronics manufacturing are driving R&D toward higher adsorption rate, better energy efficiency, and sustainable materials. Carbon filter media with enhanced micro-porosity and polymer composites—such as those offered by Fangyu—lead industry adoption for next-gen air and water quality management (ResearchGate).

| Parameter | Typical Range | Industry Standard | Value for Fangyu Product |

|---|---|---|---|

| Filtration Efficiency | 85% - 99% | >95% (PM2.5) | 98% |

| Carbon Content | 10% - 45% | >35% | 40% (customizable) |

| Adsorption Capacity (mg/g) | 350 – 1200 | >800 | 950 |

| Thickness | 2.0 – 6.0 mm | — | 2.5/3.5/4.5 mm (options) |

| Surface Area (BET, m2/g) | 600 – 1500 | >1000 | 1100 |

| Base Weight (g/m2) | 180–850 | — | 200/400/800 |

| Air Permeability (L/m²/s) | 80 – 280 | >95 | 120 |

| VOC Removal Rate | 70%–99% | >85% | 97% |

As documented in ScienceDirect and IOPscience, expertise in composite filter media engineering vastly improves filtration performance and cost-effectiveness. Hebei Fangyu Filters Material Technology Co,. Ltd. adopts strict internal protocols, third-party testing, and reference international standards such as ISO/TS 16949 and GB/T 32085 to ensure all activated carbon filter media surpass the industrial quality benchmarks.

Explore our innovative activated carbon filter for sale product line today and experience world-class OEM solutions tailored to your project demands. For project inquiries, custom requests, and detailed data sheets, contact our engineering team or visit our website.

Thickness:0.2-6 mm or Customized

Strand Thickness:0.5-8mm

Swd:2.5-100mm Lwd: 4.5-200mm

Surface Treatment:Powder Coated,Galvanized

MATERAL: PHENOLIC PAPER

MELT-BLOWN PBT

NON-WONEN LAMINATES

DIESEL FUEL FINE FILTERATION GRADE

APPLICATION : FUEL OIL WATER SEPERATION FILTER MEDIA

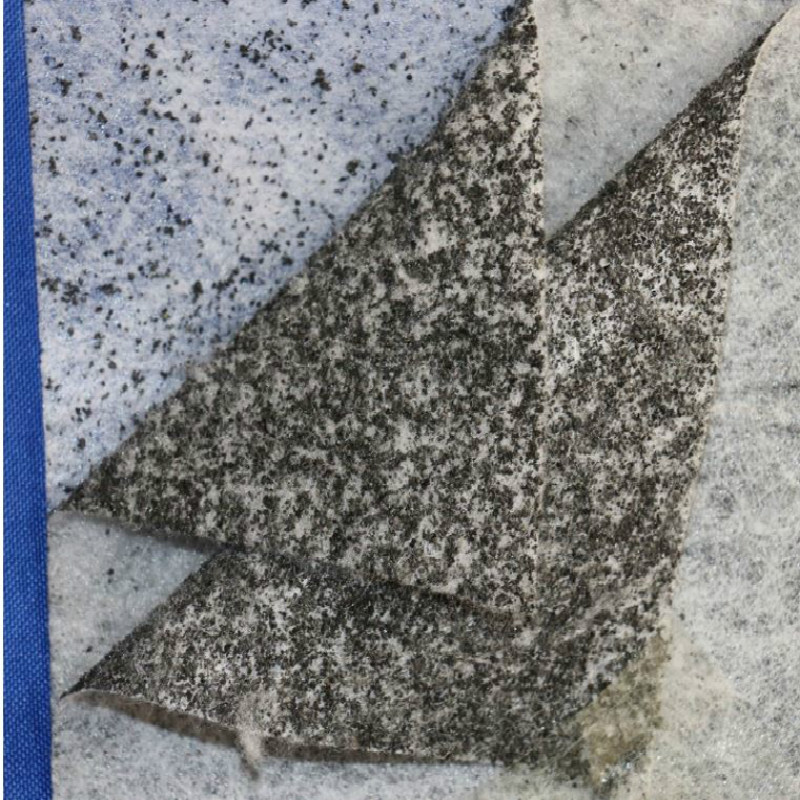

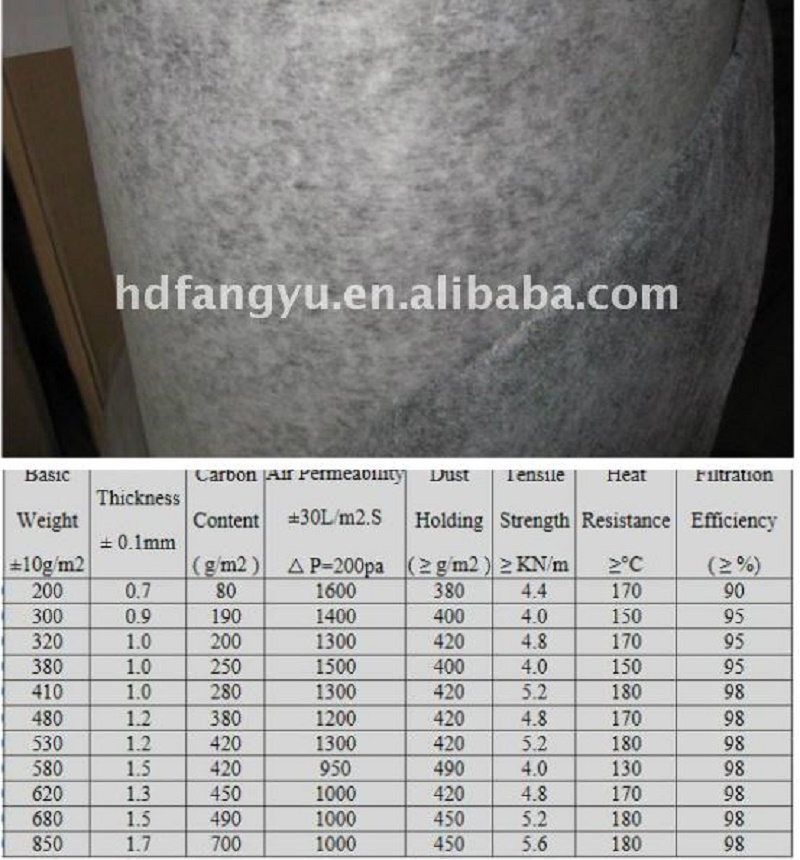

Material: Electrostatic cotton with activated carbon

PET/PP with Activated Carbon

Basic weight: 200-800g/m2

Application: Cabin Air Filters Panel Air Filters, Filter Cartridge, etc.

RAW MATERIAL: Polypropylene

PROCESS TECHNOLOGY: Melt-blown non-woven

RANGE OF EFFICIENCY: M5 ~ H11

Email to this supplier