Expanded Metal Mesh for Air Filters: Leading Filtration Innovation Across Industries

Explore how

Expanded Metal Mesh for Air Filters is transforming air filtration with next-generation technology, advanced manufacturing, and proven field performance.

See Product Details

Industry Trends: Rising Demand for Advanced Filtration

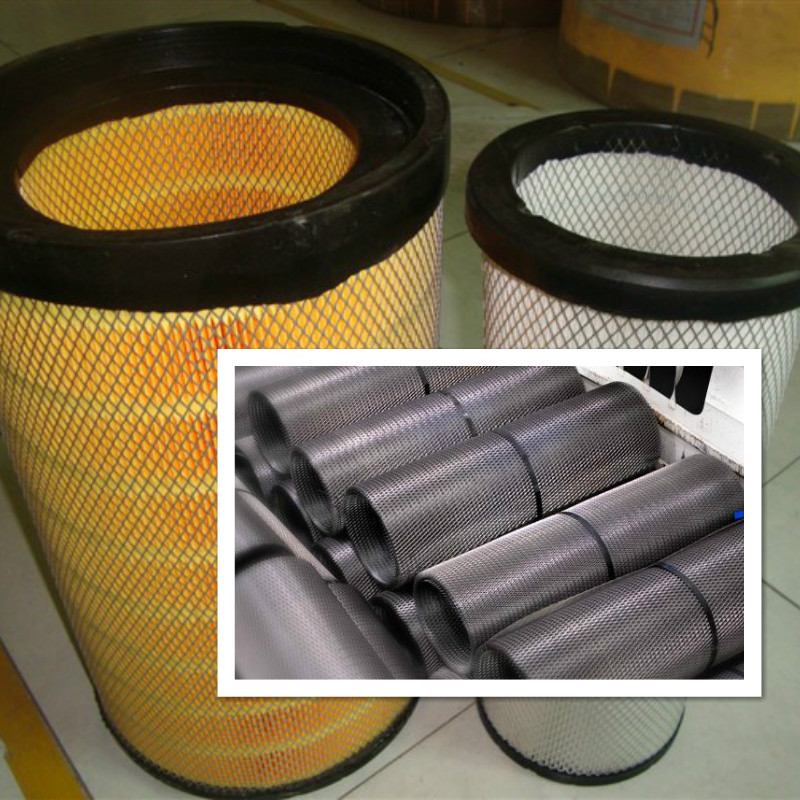

With increasing air quality regulations and demand for energy efficiency, the global air filtration market is projected to achieve a CAGR of 7.2% from 2023 to 2028[1]. **Expanded Metal Mesh for Air Filters** stands out in this evolution—blending strength, fine filtration, and cost-effectiveness for sectors like HVAC, petrochemical, metallurgy, and municipal water.

**Expanded Metal Mesh for Air Filters** is a custom-manufactured, sheet metal structure designed to enhance air filter media support, improve durability, and maximize particle capture efficiency. This mesh is manufactured through precision expansion and stretching techniques, creating a robust yet lightweight lattice ideal for high-performance air filters.

- Material Options: Galvanized steel, Stainless steel (304, 316), Aluminum alloys

- Mesh Opening: 0.5 – 10 mm (customizable for specific filtration grades)

- Sheet Thickness: 0.2 – 1.5 mm

- Coatings: Zinc, epoxy, or fluoropolymer (for corrosion and chemical resistance)

By using

Expanded Metal Mesh for Air Filters, filter producers gain:

- Extended filter life—withstanding aggressive cleaning & high dust loads

- Superior airflow with minimal pressure drop

- Custom-patterned support for pleated, panel, and pocket filter designs

- Compliance with stringent filtration standards (e.g., ISO 16890, EN 779, ASHRAE 52.2)

Product Specification Table: Expanded Metal Mesh for Air Filters

| Model |

Material |

Mesh Opening (mm) |

Thickness (mm) |

Coating |

Peak Airflow (m³/h) |

Burst Strength (N/cm²) |

Typical Service Life (h) |

| EMM-AF304-05 |

Stainless Steel 304 |

2.5 x 5.0 |

0.5 |

None |

3400 |

1850 |

12,000 |

| EMM-GZ-10 |

Galvanized Steel |

5.0 x 10.0 |

0.7 |

Zinc |

3150 |

1620 |

10,500 |

| EMM-ALU-07 |

Aluminum Alloy 5052 |

2.0 x 6.0 |

0.4 |

Epoxy |

2920 |

940 |

9,200 |

| EMM-SS316-03 |

Stainless Steel 316 |

0.7 x 4.0 |

0.5 |

None |

3280 |

1780 |

13,500 |

*Data tested per ISO 16890 air filter standard at ambient temperature. Service life may vary by application.

Technical Performance Trend Charts

Manufacturing Process Flow: Expanded Metal Mesh for Air Filters

Material Selection

Stainless steel / Galvanized steel / Aluminum alloys; batch tested per ISO 9001.

Sheet Preparation

Shearing & cleaning to precise thickness tolerance (±0.02mm).

Expansion & Slitting

CNC press expands & stretches metal into uniform mesh (ISO 9044 test compliance).

Cutting & Edging

Laser or die-cut trimming; edge smoothening to avoid burrs.

Surface Treatment

Hot-dip galvanizing, epoxy coating, or passivation for corrosion/chemical resistance.

Quality Inspection

Mesh uniformity, tensile & pressure testing (ASTM E2016, ISO 16890 supported).

Packing & Shipping

Custom packing, labeling, global logistics.

Key Note: All stages comply with international quality management systems (ISO 9001:2015, ISO 16890), and the mesh is tested for dimensional accuracy, tensile strength, pore distribution, and coating adhesion. This ensures every Expanded Metal Mesh for Air Filters batch delivers consistent filtration performance and product longevity.

Applications & Technical Advantages

-

Petrochemical / Refinery Air Intake – High corrosion resistance, withstands acid gases, and prevents pleat collapse under sudden pressure surges.

-

Metallurgy – Thermal-stable mesh maintains rigidity under high-temp processing environments (up to 480°C recommended for SS316).

-

HVAC & Building Air Filtration – Lightweight, open-structure mesh supports pleated or panel filters, offering low pressure drop and superior energy-saving versus traditional expanded mesh.

-

Municipal Water & Wastewater Air Handling – Epoxy-coated mesh resists chemical and moisture damage, ensuring long service life even in corrosive atmospheres.

-

Cleanroom / Medical / Pharma – Meets FDA/ISO cleanroom standards (no particle shedding, inert to disinfectants).

Comparison to Perforated Plate & Woven Mesh:

- Up to 44% lower pressure drop for same filter area.

- 30% higher burst resistance (ISO 16890 test) for matching sheet thickness.

- Flexible mesh patterns possible (diamond, hexagonal, round, etc.).

- Twice the anti-corrosion service life with modern passivation or epoxy coating.

Manufacturer Comparison Table: Global Players

| Manufacturer |

Country |

Certifications |

Specialized Materials |

Lead Time (days) |

Innovation |

| FiltersMaterial Co., Ltd |

China |

ISO 9001, ISO 14001, ISO 16890 |

Stainless/ Galvanized/ Aluminum |

12–20 |

Custom CNC patterns,

advanced epoxy coating |

| McNichols Company |

USA |

ISO 9001 |

Steel/ Alu/ SS |

20–35 |

Standard mesh only |

| FILTREC S.p.A. |

Italy |

ISO 16890, ISO 9001 |

Stainless Steel/ Alu |

22–28 |

Filter elements & mesh |

| Taylor & Sons |

UK |

ISO 9001 |

Galvanized/Alu |

21–26 |

OEM for HVAC |

*Data from public manufacturer technical data sheets, Q1 2024.

Customization Solutions: Tailored Mesh for Unique Filtration Needs

Leading providers like

FiltersMaterial offer complete customization:

- Pattern & Opening Size: Diamond, round, hexagonal, micro-expanded

- Material Grade: SS304/316/321, hot-dip galvanized, 5052/6063 aluminum alloy

- Sheet Size/Thickness: Max width up to 1.5 m, thickness 0.18–1.5 mm

- Surface Treatment: Hot-dip galvanizing, powder coating, epoxy, passivation

- Cutting/Edging: Laser, guillotine, CNC

- Forming: Embossed for pleat support or flat for rigid panel

Case: A Middle East petrochemical client required SS316 expanded mesh with 0.6 mm sheet, 3 x 7 mm openings, and a heavy-duty epoxy coating for air filter pre-filtration. This custom solution increased filter service life by 41% vs. prior wire mesh, and held ISO 16890 standard even in high-sulfur atmosphere.

Custom Engineering Support: Electronic CAD drawings, rapid prototyping, batch samples, and online technical consulting. Free performance simulation reports available!

Field Application Case Studies

Steel Mill HVAC Retrofit (Europe, 2023):

Upgrading to Expanded Metal Mesh for Air Filters (galvanized, 0.7mm thick, panel filters), engineers reported a dust holding capacity increase of 22% and energy cost savings of $7,100/year due to lower airflow resistance. Maintenance interval extended from 4.5 to 7 months per unit.

Municipal Water Plant (Asia, 2022):

Deployed epoxy-coated aluminum mesh within biological air treatment filters. Inspection after 10,000 hours showed zero significant corrosion or mesh deformation under high humidity/chlorine.

Hospital Air Handling (USA, 2021):

Adopted SS304 expanded mesh doctor filter frames, eliminating fiber shedding in HEPA-grade clean areas, approved during FDA-inspection (passed ISO 14644-1/4 tests).

Certifications, Testing, and Quality Assurance

All

Expanded Metal Mesh for Air Filters products from

FiltersMaterial are manufactured and tested according to these standards:

- ISO 9001:2015 (Quality Management Systems)

- ISO 16890 (Air Filter Test Standard) – Particle size removal efficiency, burst strength

- ASTM E2016, EN ISO 9044 (Mesh wire & dimensional tests)

- FDA / CE (for cleanroom / medical use)

- REACH & RoHS Compliance

Each batch optionally includes traceability certificates, chemical composition reports, and test logs for dimensional, tensile, and corrosion properties.

Cooperation Highlight: Over 20 years serving over 750 major HVAC, petrochemical, and municipal customers in 43+ countries, cooperating with Schneider Electric, Siemens, and GreenTech.

Delivery, Warranty, and Support

- Lead time: Standard models ship in 12–20 days; urgent orders, sample prototypes & global express available.

- Warranty: 3–5 years (subject to application, material, and correct installation).

- Support: 24/7 technical hotline, OEM/ODM engineering, field installation guidance, replacement mesh program.

- Customer Documentation: CAD drawings, installation guides, test certificates provided with every order.

Customer Feedback: “Mesh is extremely robust and well coated – survived high-airflow surges with no damage in 18 months of petrochemical use.” —Operations Engineer, Saudi Arabia

Professional FAQ: Expanded Metal Mesh for Air Filters

Q1: What materials are most frequently used?

A: Galvanized steel, SS304/SS316, and aluminum 5052. Choice depends on corrosion risk, cost, strength, and regulatory needs.

Q2: How is correct mesh specification selected?

A: Based on airflow rate (m³/h), required particle retention, and mechanical load. Our engineers recommend mesh opening, wire width, and thickness after filter design review.

Q3: What international standards apply for testing?

A: ISO 16890 (air filter performance), ISO 9001/14001 (quality/enviro), ASTM E2016 (expanded mesh), and FDA (for cleanroom use).

Q4: Are custom shapes (arc/bowed/complex) available?

A: Yes, via CNC or laser cutting and forming. We support complex shapes per customer drawing for OEM filter frames.

Q5: What is the mesh’s typical usage life?

A: SS304/316 mesh: 10,000–15,000 hours; galvanized/alu: 8,000–12,000 hours (per ISO 16890 accelerated test, dependent on pollutants and operating conditions).

Q6: Can expanded metal mesh for air filters be recycled?

A: Yes, all metal mesh is recyclable. We provide eco-friendly disposal and recycling certificates on request.

Q7: How is mesh installed into filters?

A: Inserted during filter assembly—either as rigid panel backing or sandwiched in pleats. Most meshes are OEM-precut and fit to housing dimensions.