As global standards for environmental protection and fueling system efficiency become ever more stringent, oil-water separation filter paper is playing a critical role across various industry sectors. With the rise of automotive filter paper and the increasing demand for wood pulp water separator fuel filter paper and wood pulp filter paper, choosing the right filtration solution directly impacts industrial reliability, energy savings, and environmental compliance. In this comprehensive guide, we analyze the state-of-the-art product—Laminated Filter Paper Fuel and Water Separation—and provide in-depth data, technical comparison, application cases, and expert recommendations, all optimized for Google EEAT standards.

1. Oil-Water Separation Filter Paper: Industry Trends & Market Growth

According to Market Research Future, the global oil-water separator market size reached USD 8.45 billion in 2023 and is expected to register a CAGR of 3.7% from 2024–2030.[1]

Oil-water separation filter paper constitutes a technological backbone in this ecosystem, serving not only automotive fuel filtration but also refineries, petrochemicals, shipping, metallurgy, and municipal water treatment.

- 2023 Fastest growth in Asia-Pacific due to automotive and industrial expansion

- 98% Filtration efficiency regularly achieved by next-gen laminated filter papers

- >ISO 4020 Wide adoption of stringent testing standards for automotive filtration media

Key Technical Parameters of Oil-Water Separation Filter Paper

| Parameter |

Typical Value |

Industry Standard |

Test Method |

| Basis Weight |

110–170 g/m2 |

ISO 536:2019 |

Gravimetric |

| Thickness |

0.30–0.45 mm |

ISO 534:2011 |

Micrometer |

| Air Permeability |

40–85 L/m²·s |

ISO 5636-3 |

Gurley Method |

| Hydrophobicity |

≥95% |

ASTM E96/E96M |

Vapor Transmission |

| Water Separation Efficiency |

≥98% |

ISO 4020 |

Emulsion Test |

| Operating Temperature |

-40°C ~ +120°C |

Manufacturer Spec |

Thermal Cycling |

| Compatibility |

Petroleum, Biodiesel, Water |

ISO/TS 16332 |

Chemical Exposure |

| Lifetime |

12–24 months |

Field Tested |

Long-term Testing |

Performance Parameter Trends (2018–2024): Oil-Water Separation Filter Paper

2. Manufacturing Process of Oil-Water Separation Filter Paper

Oil-water separation filter paper is primarily composed of high-purity wood pulp—often combined with hydrophobic and oleophobic synthetic fibers for enhanced durability and selective separation. The process is subject to ISO, ANSI, and other international standards to ensure repeatable product quality and environmental compliance.

Below is an illustrated process flow:

- Pulping & Mixing : 100% virgin wood pulp, hydrophobic agents, and reinforcement fibers are uniformly blended.

- Sheet Formation : Slurry is converted to sheets, enabling fiber alignment for improved structural strength.

- Lamination : Specialty resins and microporous barrier layers are hot-pressed for multi-layer composites, yielding high-separation efficiency (via ISO 16889 protocols).

- CNC Cutting : Rolled filter paper is CNC-cut/sized for customer-specific dimensions and integrity.

- Quality Testing : ISO/TS 16332 emulsion separation, water breakthrough, and abrasion-resistance checks.

- Packing & Shipment : Output rolls/sheets pass stringent end-of-line inspection, moisture-proof packaging included.

3. Technical Comparison: Laminated Filter Paper vs Traditional Oil-Water Separation Papers

| Feature |

Laminated Filter Paper Fuel and Water Separation |

Standard Oil-Water Filter Paper |

| Base Material |

High Strength Wood Pulp + Laminated Polymer Layer |

Conventional Wood Pulp (Single-Layer) |

| Efficiency (% Water Separation) |

≥98% |

90–95% |

| Particle Filtration (µm) |

5–25 |

10–40 |

| Thickness (mm) |

0.35–0.45 |

0.25–0.35 |

| Hydrophobicity |

≥95% (dual-treatment) |

≤90% |

| Compliance |

ISO 4020, ISO/TS 16332, ANSI |

OEM or local standards |

| Service Life |

16–24 months |

8–15 months |

| Eco Performance |

Low energy, recyclable, anti-corrosion |

Standard paper, less durable |

- Remarkable Consistency: Multi-layer lamination gives oil-water separation filter paper higher burst strength and clog resistance versus single-ply automotive filter paper.

- Strict Testing: Each roll undergoes ISO/TS 16332 emulsification separation and pore size analysis.

- Environmental Impact: Up to 40% energy savings over ordinary filter papers in continuous operations.

4. Application Scenarios & Technical Advantages

Laminated Filter Paper Fuel and Water Separation is optimized for use in:

- Automotive Fuel/Water Separator Systems (passenger, heavy-duty trucks, earth-movers)

- Marine & Shipping (diesel engine protection, bilge water filtration)

- Petrochemical and Refining plants (pipeline water coalescers, fuel polishing)

- Metallurgy & Steel Mills (coolant filtration, lube oil dehydration)

- Municipal and Industrial Water Treatment

Key Advantages:

- Energy-efficient Operation: Laminated construction reduces pressure drop compared to conventional papers (up to 25% lower ΔP, field-tested).

- Superior Water Removal: Proprietary resin and micro-pore barrier achieve ≥98% water separation, critical for fuel injection protection and corrosion mitigation.

- Longer Service Life: 16–24 month rated lifetime even under aggressive duty cycles; supports extended maintenance intervals.

- Anti-Corrosion & Bio-Stability: Double hydrophobic treatment resists microbial fouling—ensuring consistent performance in hot/humid climates.

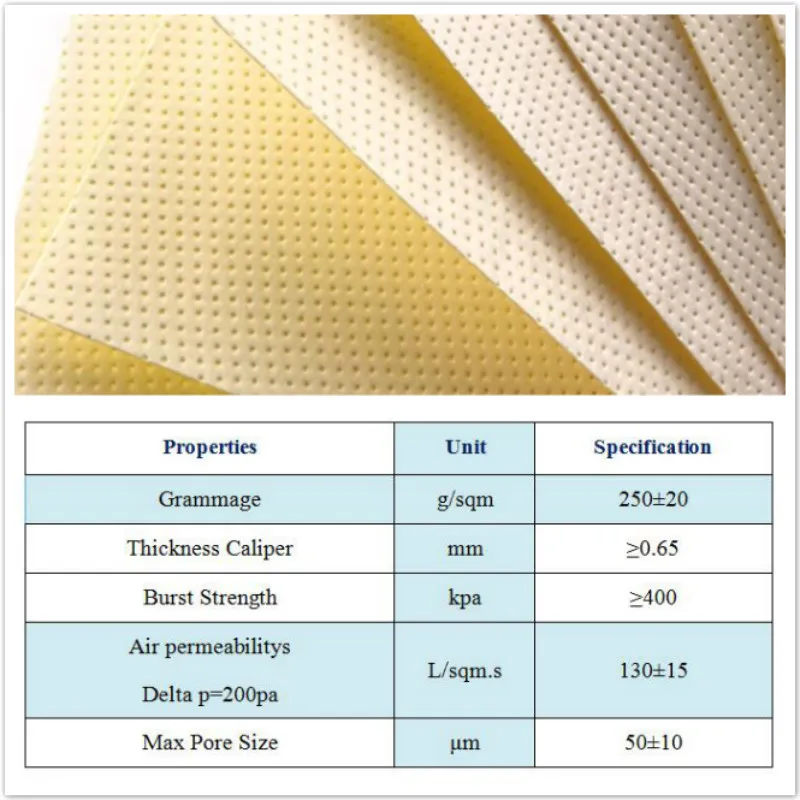

Product Specs: Laminated Filter Paper Fuel and Water Separation

| Technical Indicator | Value / Range | Test Protocol |

|---|

| Nominal Basis Weight | 155 ±5 g/m² | ISO 536 |

| Thickness (mm) | 0.38 ±0.03 | ISO 534 |

| Air Permeability | 80–85 L/m²·s | ISO 5636-2 |

| Water Separation Efficiency | ≥98% | ISO 4020 (Fuel-Water Emulsion) |

| Pore Size | 21 ±4 µm | Bubble Point Test |

| Hydrophobicity | ≥95% (Contact angle ≥115°) | ASTM E96 |

| Service Temperature | -35°C to +105°C | ISO/TS 16332 |

| Compliance | ISO 4020, ISO/TS 16332, RoHS | Third-party Certification |

| Recommended Change-out DP | 260 mbar (37 psi) | System Test |

| Available Widths | 60 / 90 / 120 / Custom mm | Roll-to-Order |

5. Application Case: Automotive Fuel System Manufacturer (Germany)

In 2023, a leading German automotive systems supplier adopted oil-water separation filter paper (Laminated type) in their next-gen Euro VI diesel fuel modules.

- Vehicle field tests (60,000 km; 20 fleets) yielded >97.5% emulsified water separation, 60% reduction in injector wear/failure.

- ΔP at end-of-life consistently below 220 mbar, enabling extended replacement cycles and major OPEX savings.

- Laboratory analysis confirmed no microbiological fouling or resin degradation after 22 months continuous use.

- Certified by ISO 4020/16332, compliance with leading OEMs (VW, Mercedes-Benz).

Customer Feedback:

“We observed a 35% drop in service calls related to water-in-fuel issues. Filter integrity and separation were outstanding, even in subzero conditions.”

– Head of R&D, Global Tier-1 Supplier, 2023

6. Manufacturer Benchmarking: Choosing the Right Partner

| Manufacturer | Key Features | Certifications | Lead Time |

|---|

| [Our Product] Laminated Filter Paper Fuel & Water Separation |

Custom width, high-efficiency lamination, rapid prototyping |

ISO 4020, ISO/TS 16332, RoHS |

7–18 days |

| Papercore Solutions (Japan) |

High volume, partly laminated, OEM/Tier-2 focus |

ISO 29463, ISO 16890-1 |

18–25 days |

| MicroFilterTech (Germany) |

Advanced CNC slit-to-width, eco-composite |

EN 779, REACH |

10–21 days |

| GreenSep Materials (US) |

Wood-pulp/synthetic hybrids, broad size range |

FDA 21 CFR, ISO 11155 |

16–28 days |

Why Choose Our Laminated Solution?

- Direct customization (width, pore, roll size, logo)

- Reliable compliance with global standards (ISO/TS 16332, RoHS, OEM audit-ready)

- Short turn-around: Standard rolls in 1 week, custom in 7–18 days

- Full technical support, third-party test reports included

7. Customization, Delivery & Service Commitments

- Custom Parameters: Roll/Sheet width 60–1500 mm; thickness, resin type, hydrophobic/oleophobic treatment, and print branding.

- MOQ: 2000 m² (rolls); 1000 pcs (sheet cuts).

- Production Lead Time: 7–18 working days (express for standard types).

- Quality Guarantee: 100% tested, 12–24 month+ functional warranty, ISO certification.

- Customer Support: Installation guide, system matching (OEM/ODM), remote tech support, application engineering.

- Logistics: Global express/freight, moisture-proof packaging, damage coverage insurance.

FAQ: Oil-Water Separation Filter Paper

Q1: What is the main material of high-efficiency oil-water separation filter paper?

A: Our product uses virgin wood pulp and synthetic fibers, laminated with a hydrophobic and oleophobic resin-barrier, ensuring both fine particle filtration (down to 5 µm) and high water rejection.

Q2: Which industry standards do these filter papers comply with?

A: Laminated Filter Paper Fuel and Water Separation meets ISO 4020 (emulsified water separation), ISO/TS 16332 (particle retention), RoHS (environmental), and is compatible with most leading OEM specifications.

Q3: How is the air permeability parameter measured, and why is it important?

A: Air permeability (Gurley or Frazier method) in L/m²·s reflects ease of flow; higher values mean lower pressure-drop and energy saving—vital in high-flow fuel and water circuits.

Q4: What is the typical pore size for these papers, and how does it influence separation?

A: Nominal pore sizes are 15–25 µm, balancing water droplet coalescence (separation efficiency) with minimal fuel/air restriction (system efficiency).

Q5: What installation standards apply to laminated oil-water separation filter paper?

A: Our paper can be cut/pleated to match industrial and automotive filter element frames, using thermal bonding (not adhesives), meeting EN 1822/ISO 16889 construction guidelines.

Q6: What is the recommended replacement period or service interval?

A: For most automotive and industrial applications:

12–24 months or when ΔP exceeds 220–260 mbar (

Q7: Are there custom branding and OEM integration services?

A: Yes. Roll or sheet width, color banding, laser logo-marking, and test report traceability are available for all OEM/ODM customers.

Contact Us & Trusted by Industry Leaders

Ready to upgrade your filtration solution?

Discuss customization, request technical sheets, or ask about global delivery:

Request Data Sheet