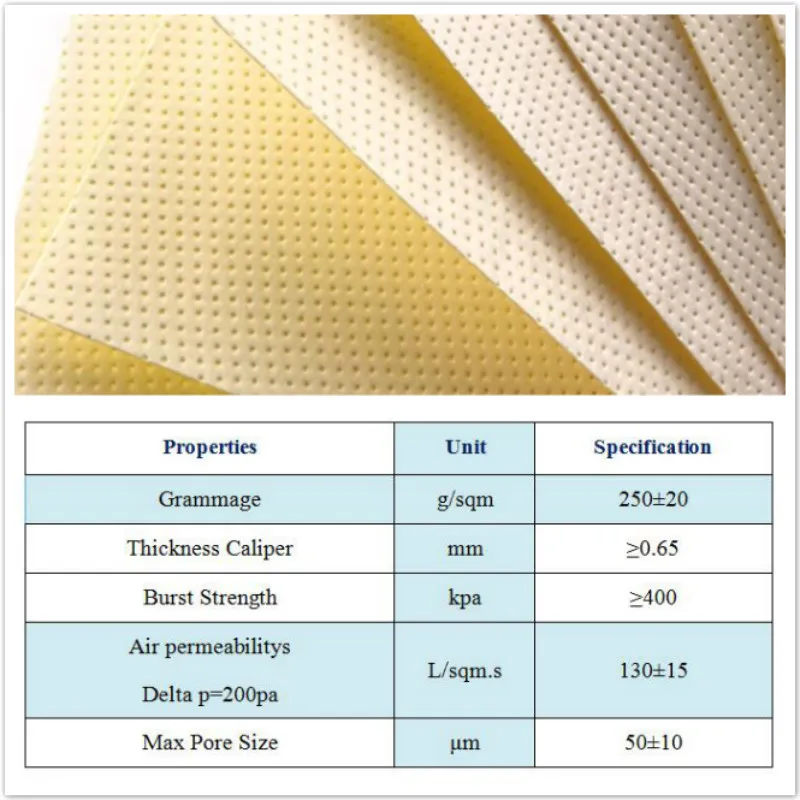

| Parameter | Typical Value | Unit | Industry Standard / Spec | Remarks |

|---|---|---|---|---|

| Material Composition | Phenolic paper / Melt-blown PBT, Wood Pulp, Synthetic Fibers | - | ISO 9001, TS16949 | Preferred for fuel & water separation |

| Separation Efficiency (Water) | 98~99.5% | % | ISO 4020, JIS D1611 | At 10-30 μm particle size |

| Filtration Grade | 5~15 | μm | ISO 16889 | For fine diesel fuel filtration |

| Basis Weight | 140~250 | g/m2 | Customizable | Higher weight for higher efficiency |

| Air Permeability | 65~180 | L/m²/s | GB/T 5453 | At 200 Pa differential pressure |

| Wet Strength | >1.7 | kN/m | GB/T 12914 | Important for fuel filter operation |

| Thickness | 0.36~0.65 | mm | - | Varies by application |

| Max Operating Temp. | 120~175 | ℃ | OEM Spec | Depends on resin and fiber blend |

Thickness:0.2-6 mm or Customized

Strand Thickness:0.5-8mm

Swd:2.5-100mm Lwd: 4.5-200mm

Surface Treatment:Powder Coated,Galvanized

MATERAL: PHENOLIC PAPER

MELT-BLOWN PBT

NON-WONEN LAMINATES

DIESEL FUEL FINE FILTERATION GRADE

APPLICATION : FUEL OIL WATER SEPERATION FILTER MEDIA

Material: Electrostatic cotton with activated carbon

PET/PP with Activated Carbon

Basic weight: 200-800g/m2

Application: Cabin Air Filters Panel Air Filters, Filter Cartridge, etc.

RAW MATERIAL: Polypropylene

PROCESS TECHNOLOGY: Melt-blown non-woven

RANGE OF EFFICIENCY: M5 ~ H11

Email to this supplier