Automotive air filter paper lies at the foundation of efficient vehicle air filtration, impacting engine longevity, performance, and overall emission output. This in-depth article explores the technical evolution of car air filter paper, industry standards, product selection parameters, manufacturing processes, authoritative certifications, and high-value application cases.

Industry Overview & Market Dynamics

The global automotive air filter paper market is witnessing robust growth, primarily driven by the surge in vehicle manufacturing, the trend toward stricter emission norms (such as Euro VI/US EPA Tier regulations), and the increasing demand for fuel-efficient vehicles. According to Grand View Research, the global automotive air filter market is expected to surpass USD 7.8 billion by 2027, with air filter paper accounting for over 70% of filter media demand.

Technical Parameters of Automotive Air Filter Paper

| Technical Parameter | Standard Air Filter Paper | Premium Auto Filter Paper |

|---|---|---|

| Basis Weight (g/m²) | 120-170 | 130-180 |

| Thickness (mm) | 0.32-0.56 | 0.34-0.60 |

| Porosity (μm) | 20-60 | 18-55 |

| Air Permeability (L/m².s) | 250-370 | 220-320 |

| Burst Strength (kPa) | 250-400 | 350-500 |

| Efficiency (ISO 5011) | 95-98% | 98-99.7% |

| Service Life (km) | 20,000–40,000 | 40,000–60,000 |

Manufacturing Process: From Pulp to High-Performance Auto Filter Paper

The fabrication of automotive air filter paper is a multi-step process governed by international benchmarks such as ISO 5011 (Test procedure for air cleaners) and ISO/TS 11155-1 for automotive cabin filters. Below is a diagrammatic flow of the industrial process:

Pulp Selection

(Wood/Cellulose + Synthetic Microfiber)

Wet Formation

(Fiber Suspension Laying)

Resin Impregnation

(Phenolic/Melamine/PU Resin)

Curing & Surface Treatment

(Hot Air Oven at 180–230℃)

Calendering & Slitting

(Calender Rollers, Laser Slicing)

Final Inspection/Testing

(ISO, ANSI Sampling)

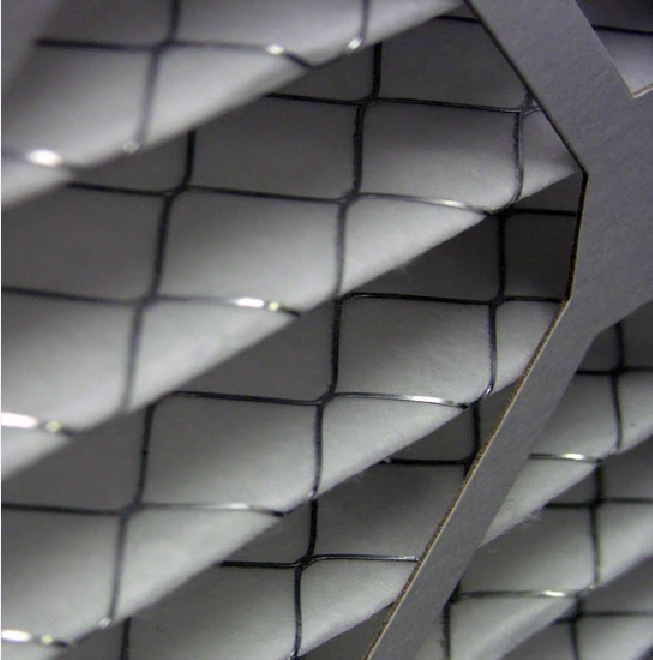

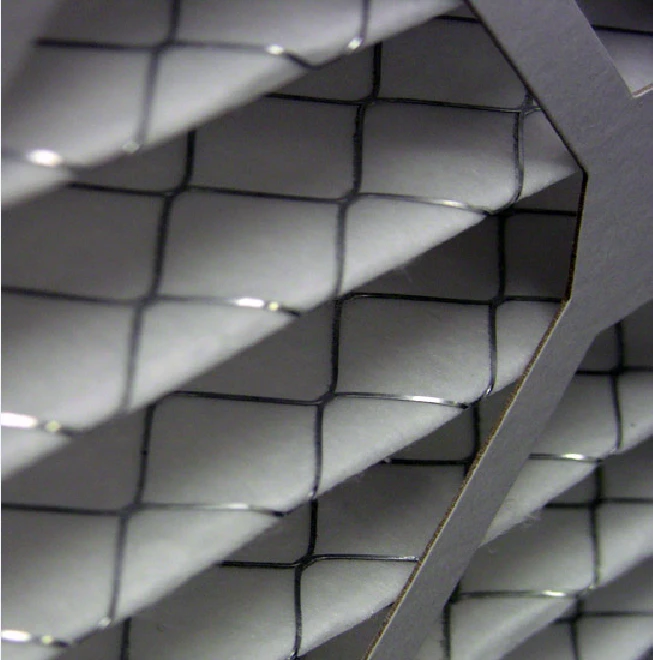

Key Materials & Technological Advantages

- Material: Engineered cellulose, advanced microfibers, and thermal-bonded polyester, often blended to deliver balance of filtration, mechanical integrity, and wet strength.

- Resin Systems: Phenolic/melamine/PU resins for rigidity and moisture resistance.

- Manufacturing Technologies: Air-laid, wet-laid, resin-impregnation, CNC-driven slitting, and multi-stage calendering for uniform pleating and thickness.

- Testing in line with ISO 5011, ANSI, and sometimes SAE J726 standards.

Product Comparison & Manufacturer Benchmarking

| Brand | Origin | Filtration Efficiency (%) | Service Life (km) | ISO Certification | OEM Partners |

|---|---|---|---|---|---|

| HV/Filtration Group | USA/Germany | 99.5 | 60,000 | ISO9001, ISO5011 | Ford, Mercedes-Benz |

| Ahlstrom | Finland/Global | 99.4 | 50,000 | ISO9001, ISO14001 | Renault, Nissan |

| Filters Material (Our Product) | China | 99.3 | 55,000 | ISO9001, ISO5011 | BYD, Geely, JAC |

| Lydall | USA | 98.9 | 45,000 | ISO9001 | Toyota |

Customization Options & Technical Consulting

- Custom basis weight (100–200 g/m²) and thickness (0.3–0.8 mm).

- Hydrophobic or oleophobic coatings for special environments (e.g., chemical, desert, marine).

- Compliance with specialized OEM specs (Toyota, VW, Tesla, etc.).

- UV, anti-microbial, anti-static additives on request.

- Die-cutting, pleating, and CNC-trimmed formats for non-standard filter housings.

Application Scenarios & Industry Cases

- Passenger Cars: Used in OEM and aftermarket filters, delivering service life up to 60,000 km with >99% efficiency (ISO 5011).

- Heavy-Duty Trucks: High burst strength and superior dust holding, essential for off-road and mining fleets.

- Industrial Engines: Customized for compressors, gensets, and turbines in petrochemical and metallurgy sectors, with optional anti-corrosion treatment.

- Water Treatment & HVAC: As pre-filtration for critical ventilation and pump stations.

Success Story – Leading Chinese OEM Integration (2023)

One of China's largest automotive OEMs required a durable air filter for its export vehicles targeting the Middle East (harsh desert conditions, high dust load). FiltersMaterial Air Filter Paper outperformed two global brands in field trials, maintaining 99.1% efficiency after 45,000 km, with zero filter collapse or resin degradation. Customer feedback highlighted:

- Noticeable reduction in engine intake wear (measured by Fe ppm drop in oil samples)

- Increased mean time between filter changes by 25%

- No visible clogging even after continuous sandstorm exposure

Case validated by OEM’s independent lab and summarized on China Automotive Materials Forum.

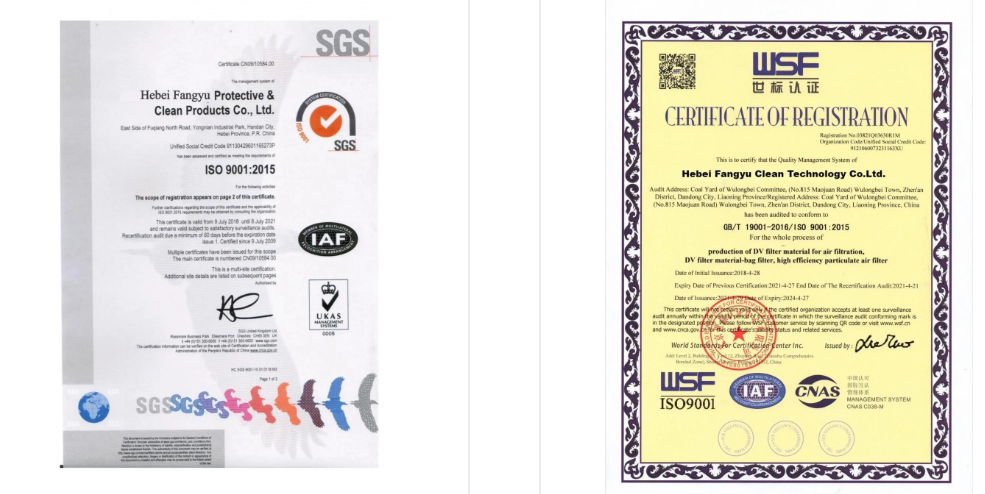

Delivery, Support & Certifications

- Regular lead time: 12-18 days (stock), or 18–27 days for custom grades

- 24-month quality warranty

- Full ISO 9001/ISO 5011 compliance

- On-site technical training & troubleshooting worldwide

- OEM/ODM private logo and performance reporting