In the rapidly evolving world of air filtration, filter media such as HEPA, nonwoven synthetic, and activated carbon solutions are playing an increasingly pivotal role across industries, from petrochemicals to metallurgy. Among leading products, Laminated Air Filter Media With Mesh stands out for its robust construction, precise technical specifications, and superior performance. This article provides an in-depth look at the latest industry dynamics, manufacturing processes, technical data, typical use cases, and a comprehensive comparison within the filter media category.

1. Filter Media Industry Landscape & Market Trends

The global filter media market was valued at over USD 23.1 billion in 2023 and is projected to grow at a CAGR of 6.2% through 2029[1]. Key growth drivers include stricter air quality regulations (e.g., ISO 16890, EN779), rising demand for high-efficiency filtration in HVAC, cleanrooms, and industrial processes, and technological advances in synthetic and composite filter materials.

- HEPA filter media remains dominant in cleanroom and sensitive environments due to its 99.97%+ efficiency for 0.3 μm particulates.

- Nonwoven synthetic filter media (polyester, polypropylene) are valued for versatility, durability, and cost-effectiveness in general industrial and HVAC usage.

- Activated carbon air filter media is indispensable for odor and VOC removal in commercial/residential air purification.

- The supply of filter media for sale is shifting toward custom and high-performance laminated products.

Key Industry Data (2023-2024)

| Media Type |

Efficiency (EN779/ISO 16890) |

Common Thickness (mm) |

Air Flow (m3/h) |

Lifespan (hours) |

| HEPA Filter Media |

≥99.97%@0.3μm |

0.5-0.8 |

300-3600 |

5000+ |

| Synthetic Nonwoven |

M5-F9 (ISO ePM10-1) |

3-20 |

500-4500 |

2000-3500 |

| Activated Carbon |

MERV 8-13 |

6-15 |

500-4000 |

1500-2200 |

| Laminated With Mesh |

G3-F9 |

5-12 |

1000-5200 |

3500-6500 |

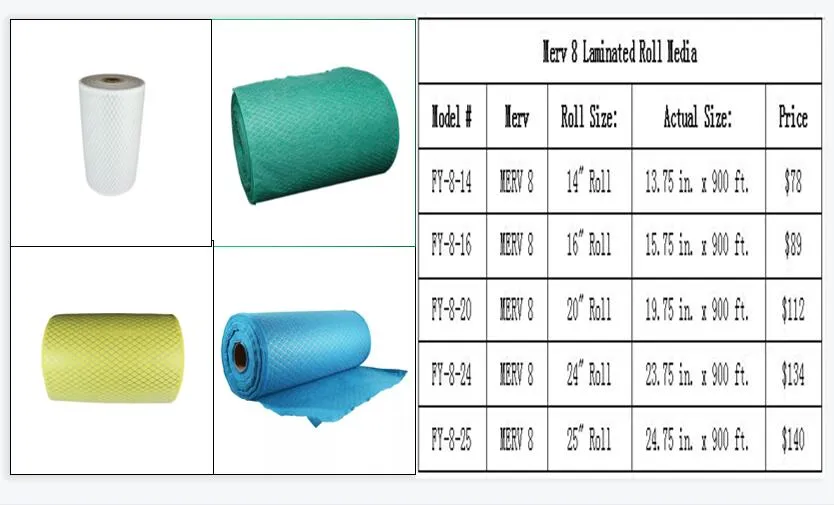

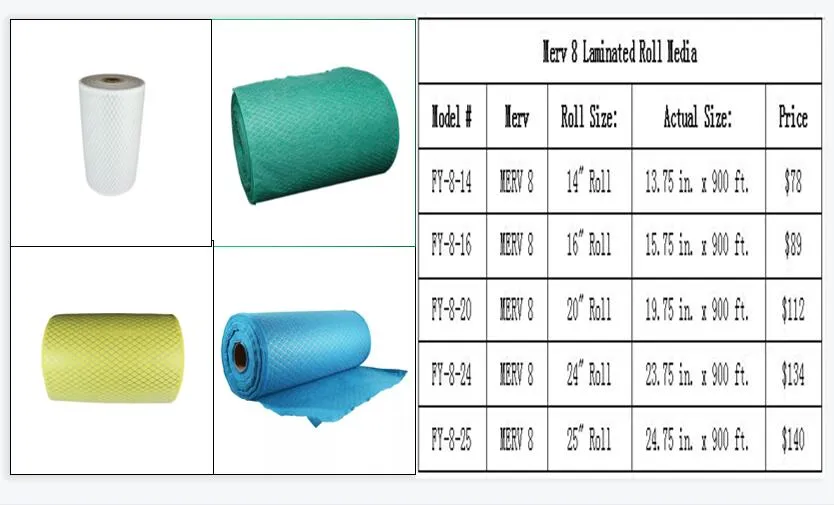

2. Laminated Air Filter Media With Mesh: Product Overview & Technical Parameters

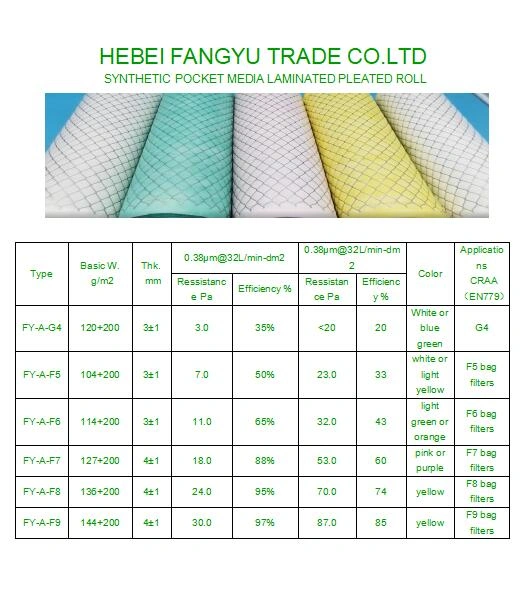

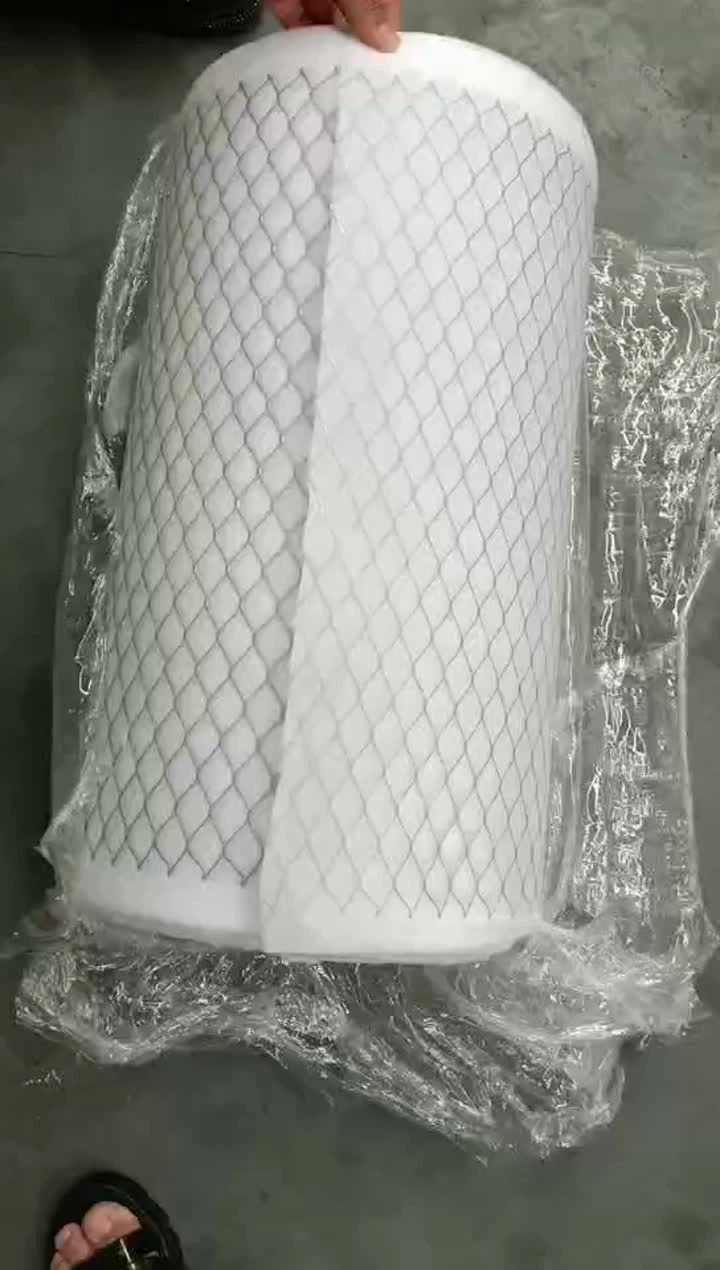

Laminated Air Filter Media With Mesh is an advanced composite filter solution designed for medium and coarse particle removal in HVAC, industrial, and commercial air handling systems. Its core advantages include multilayer nonwoven or synthetic filter media bonded to a robust metal mesh, offering exceptional rigidity, efficiency, and extended operational life.

Main Technical Specifications (Laminated Air Filter Media With Mesh)

| Parameter |

Value / Range |

| Standard Grades |

G3, G4, F5, F6, F7, F8, F9 (EN779/ISO16890) |

| Initial Resistance |

20-55 Pa (@560 m³/h) |

| Final Resistance |

≥250 Pa |

| Thickness |

5-12 mm (customizable) |

| Air Permeability |

≥3200 L/m²•s |

| Material |

100% Synthetic Nonwoven Media + Galvanized/Aluminum Mesh |

| Fire Safety |

UL 900/EN779/ISO16890 compliant |

| Lifespan (Hours) |

3,500 – 6,500 |

| Applicable Industries |

HVAC, Cleanrooms, Petrochemical, Metallurgy, Water Treatment, Pharmaceutical, Food Processing |

Comparison: Laminated Air Filter Media With Mesh vs. Other Filter Media

| Feature |

Laminated With Mesh |

HEPA |

Synthetic Nonwoven |

Activated Carbon |

| Filtration Grade |

G3-F9 |

H10-H14 |

M5-F9 |

MERV 8-13 |

| Strength/Rigidity |

Very High |

Medium |

Low-Medium |

Medium |

| Service Life (hours) |

3,500–6,500 |

5,000+ |

2,000–3,500 |

1,500–2,200 |

| Initial Pressure Drop |

Low |

Medium |

Low |

Low |

| Typical Use |

Pre/Medium Filtration, Industrial HVAC |

Cleanroom, Medical |

HVAC, General Industry |

Odor/VOC Control |

| Customization |

High |

Limited |

High |

Medium |

3. Manufacturing Process: Laminated Filter Media With Mesh

Raw Material Selection

High-quality synthetic fibers (e.g., PET, PP) & corrosion-resistant mesh.

➤

Nonwoven Formation

Carding, laying, & thermal bonding of nonwoven base layer.

➤

Mesh Integration

Precision lamination of mesh via CNC-controlled hot melt or ultrasonic welding.

➤

Cut & Roll/Sheet

Automatic cutting to custom size; rolled or sheeted as required.

➤

Testing & Packing

QA checks:

- Airflow/ISO16890/EN779 resistance testing

- Visual & physical integrity inspection

- Final sterilization (if required)

Highlight: Material Advantages

- Synthetic Nonwoven Layer: Uniform fiber distribution for high capture rates and low initial resistance.

- Mesh (Galvanized/Aluminum): Ensures excellent mechanical strength, dimensional stability, and protection against deformation in high-flow or humid conditions.

- Automated Lamination: CNC precision ensures consistent bonding, reducing defects and waste.

- Compliance: All products tested/certified to ISO16890, EN779, UL900, ANSI/ASHRAE 52.2.

Process Diagram

Schematic: Manufacturing steps of filter media with mesh lamination.

4. Data Visualization & Tech Trends

Market Volume of Major Filter Media Types (2020-2024, tons) - ECharts Line Chart

Technical Parameters Comparison (Pie) - Air Flow Capacity (%)

Laminated Filter Media Key Indexes (Bar Graph)

5. Application Scenarios & Advantages

- Industrial HVAC (Petrochemical/Metallurgy): Withstands high airflows, chemical exposure, and temperature fluctuations. Maintains filtration efficiency & low pressure drop over prolonged operation.

- Cleanrooms & Laboratories: As pre-filtration before HEPA/ULPA units, provides steady particle load reduction and extends terminal filter life.

- Municipal/Commercial Water Treatment: Prevents corrosion and dust fouling of ventilation and process equipment; mesh structure resists collapse in humid/condensing environments.

- Paint Booths & Food Processing: Ensures consistent airflow and reduces risk of fiber migration; compliant with FDA/ISO food hygiene standards[2].

Case Study: A Leading Electronics Manufacturer

Background: An ISO 9001-certified electronics plant required a long-life, high-strength filter for their HVAC system facing heavy particulate loads and frequent airflow surges.

Solution: Upgraded from standard nonwoven pre-filters to laminated air filter media with mesh. Custom roll width (950mm) and graded mesh (aluminum) were provided.

Result: Service life extended by 63% (from four months to over nine months average usage), with stable pressure drop and no deformation over the cycle. Maintenance feedback noted a 40% savings in replacement labor and lower plant downtime.

- Industry Certification: All media accredited to ISO16890 & EN779 F8; tested by SGS and China National Center for Quality Supervision of Air Filters.

6. Manufacturer Comparison & Customization Options

Major Global Filter Media Suppliers (Synthesized 2024 Data)

| Company |

Key Products |

Certifications |

Core Strengths |

Customization? |

Avg. Price (USD/sq.m) |

| FiltersMaterial™ |

Laminated Mesh, Nonwoven, HEPA, Carbon |

ISO16890, EN779, UL900, SGS, FDA |

High rigidity, advanced lamination, rapid delivery |

Yes |

5.0-7.5 |

| AAF Flanders |

HEPA, Synthetic Rolls |

UL900, ISO |

Global reach, R&D |

Limited |

6.5-10 |

| Freudenberg |

Nonwoven, Composite Mesh |

ISO9001, EN779 |

Material science expertise |

Yes |

7.0-9.0 |

| 3M |

HEPA, Carbon, Pleated |

UL900, FDA |

Brand, innovation, quality |

No |

7.5-12 |

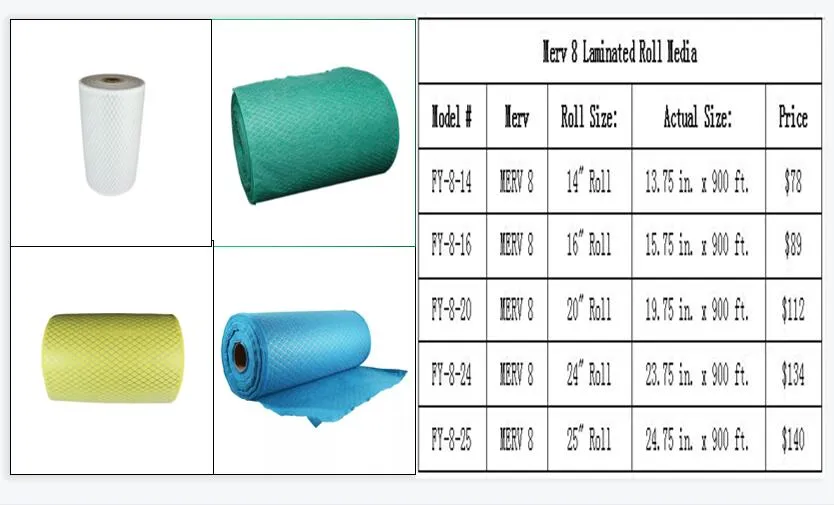

Customization Options:

- Grade: G3–F9 (EN779), ISO16890, UL900 compliance

- Thickness Range: 5–15 mm

- Mesh Type: Galvanized, Stainless Steel, or Aluminum (custom mesh size/weight)

- Dimensions: Rolls (standard 1m x 20/40m), custom sheet sizes, OEM/ODM branding

- Additional Layers: Activated carbon, antibacterial, antistatic options

7. Delivery, Warranty, and Customer Support

- Lead Time: Standard variants within 7-15 business days; custom grades within 21-28 days. Bulk worldwide shipping available.

- Warranty: 12-month product performance warranty under standard operating conditions.

- Support: 24/7 technical consultation, personalized application assessment, and onsite installation guidance (where applicable).

- Certification Documents: Complete regulatory and test documentation (ISO, EN 779, FDA, SGS) provided upon request.

8. FAQ: Professional Filter Media Terminology

Q1: What materials are typically used in laminated filter media with mesh?

A1: High-grade synthetic nonwoven fibers (typically polyester or polypropylene) are bonded with galvanized or aluminum wire mesh, offering optimal rigidity and dust loading.

Q2: How is initial resistance measured, and why does it matter?

A2: It's measured in Pascals (Pa) per ISO 16890 or EN779 standard at a set airflow (commonly 560 m³/h). Low initial resistance enables energy-efficient system operation.

Q3: What is the ISO 16890 standard and why is it important?

A3: ISO 16890 replaces EN779 as the global air filter rating system, classifying media based on particulate matter size capture (PM10, PM2.5, PM1). Compliance ensures international compatibility.

Q4: Are there specific fire safety criteria for filter media?

A4: Yes, typically UL900 (Americas) or EN779 (Europe) fire resistance standards. Laminated mesh media supplied is certified to both.

Q5: How does the mesh structure benefit industrial applications?

A5: Mesh provides enhanced physical strength, prevents filter collapse under high high volume or humidity, and maintains pleat shape—crucial in HVAC, chemical, and metallurgical sectors.

Q6: What is the difference between G3, G4, F5–F9 grades?

A6: These refer to filtration efficiency classes by EN779/ISO 16890: G3/G4 = coarse dust capture (90–95% arrestance); F5–F9 = finer particle filtration (40–95% ePM).

Q7: What is the typical installation standard for this media?

A7: Media can be installed in frames or as pleated panel filters. Ensure tight frame fit, correct airflow direction, and regular differential pressure checks. Complies with ANSI/ASHRAE 52.2, ISO16890.

9. Ready for High-Performance Air Filtration?

Laminated Air Filter Media With Mesh delivers outstanding mechanical strength, operational longevity, and compliance with all major international standards. For industry professionals seeking a reliable filter media partner, learn more here or get in touch for a custom solution.

References & Further Reading:

[1] MarketsandMarkets - Filter Media Market Report 2024

[2] ISHRAE Journal: Cleanroom Filtration Techniques

ResearchGate: Advances in Air Filtration Media

Air Filtration Forum