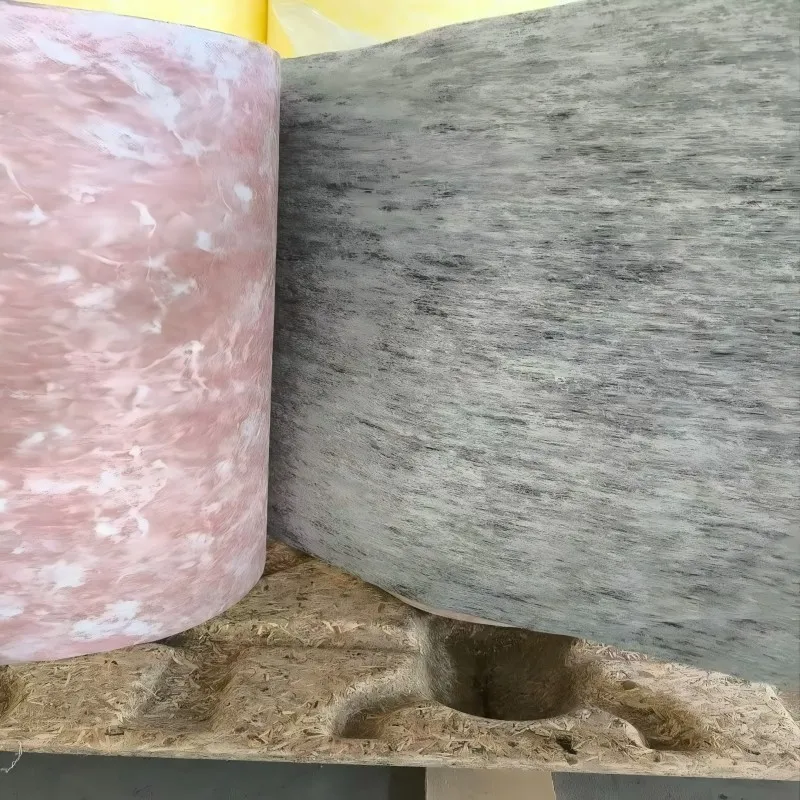

| Product Name | Fiberglass Pocket Filter Media |

|---|---|

| Technical | Laminated composites, Stitched sewing |

| Media | Ultra fiberglass fiber media |

| Filter Efficiency | F5, F6, F7, F8, F9 (According to EN779) |

| Main Features | Low Resistance, High Efficiency |

| Typical Application | Bag Filters, Panel Filters |

| More Info | Fiberglass Pocket Filter Media Detailed Page |

Fiberglass filter media stands at the forefront of modern air filtration technology, being utilized worldwide in HVAC, industrial, commercial, and cleanroom environments. As concerns regarding indoor air quality and particulate contamination grow, the demand for effective and durable filtration solutions such as fiberglass filter media, fiberglass air filter media, and fiberglass filter media rolls has notably increased.

According to leading industry forums and journals such as National Air Filtration Association and Air Filtration News, fiberglass filter media remains central in facilities that require high particulate holding capacity, moisture resistance, and consistent performance over extended service intervals.

| Type | Thickness (mm) | Weight (g/m²) | Initial Resistance (Pa) | Efficiency (EN779) | Max Temp (°C) | Humidity Resistance |

|---|---|---|---|---|---|---|

| Fiberglass Filter Media Rolls | 15-28 | 120-260 | 30-60 | F5-F9 | 250 | ≤100% |

| Fiberglass Air Filter Media | 20-25 | 140-210 | 35-58 | F6-F8 | 250 | ≤100% |

| Fiberglass Filter Material | 12-38 | 90-300 | 28-72 | F5-F9 | 250 | ≤100% |

Thickness:0.2-6 mm or Customized

Strand Thickness:0.5-8mm

Swd:2.5-100mm Lwd: 4.5-200mm

Surface Treatment:Powder Coated,Galvanized

MATERAL: PHENOLIC PAPER

MELT-BLOWN PBT

NON-WONEN LAMINATES

DIESEL FUEL FINE FILTERATION GRADE

APPLICATION : FUEL OIL WATER SEPERATION FILTER MEDIA

Material: Electrostatic cotton with activated carbon

PET/PP with Activated Carbon

Basic weight: 200-800g/m2

Application: Cabin Air Filters Panel Air Filters, Filter Cartridge, etc.

RAW MATERIAL: Polypropylene

PROCESS TECHNOLOGY: Melt-blown non-woven

RANGE OF EFFICIENCY: M5 ~ H11

Email to this supplier