1. Industry Overview and Trends

The global market for activated carbon filter for sale is expanding rapidly, driven by stringent environmental standards, water quality awareness, and rapid industrialization.

According to MarketsandMarkets, the activated carbon market is projected to grow from USD 3.6 billion in 2022 to USD 5.1 billion by 2027, at a CAGR of 7.2%.

Industry adoption is influenced by factors such as:

- Increasing demand for high-efficiency filtration in water and air treatment.

- Advancements in activated carbon filter media manufacturing technologies.

- Rising environmental compliance requirements (ISO 14001, ANSI/NSF Standard 61).

- Expanded application in petrochemical, metallurgy, municipal water, food & beverage, and electronics industries.

Key Data: Over 40% of water and wastewater treatment plants worldwide have upgraded to advanced carbon filter media since 2019 (Source:

WaterWorld).

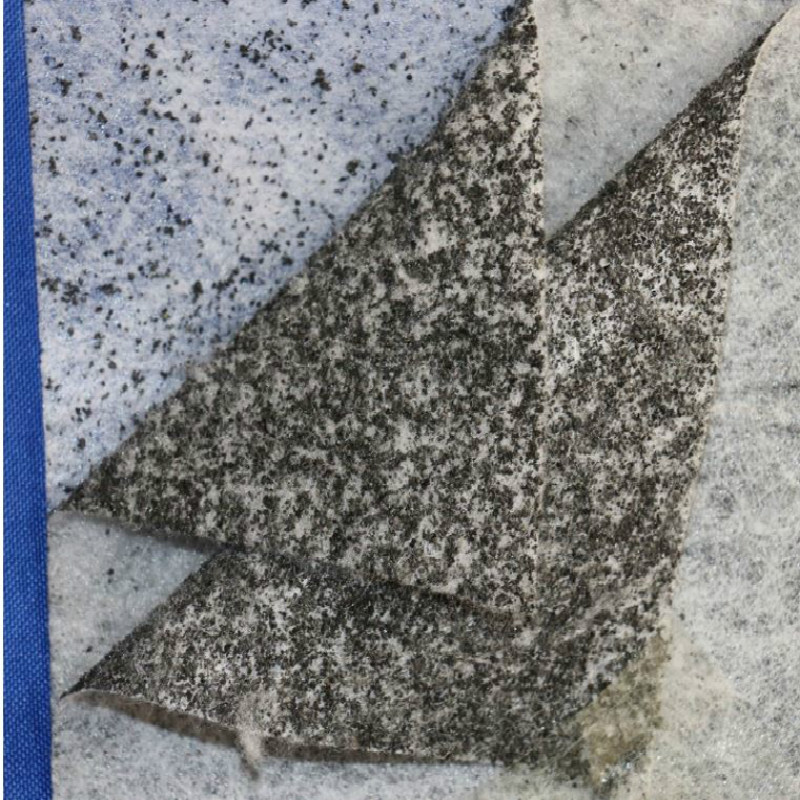

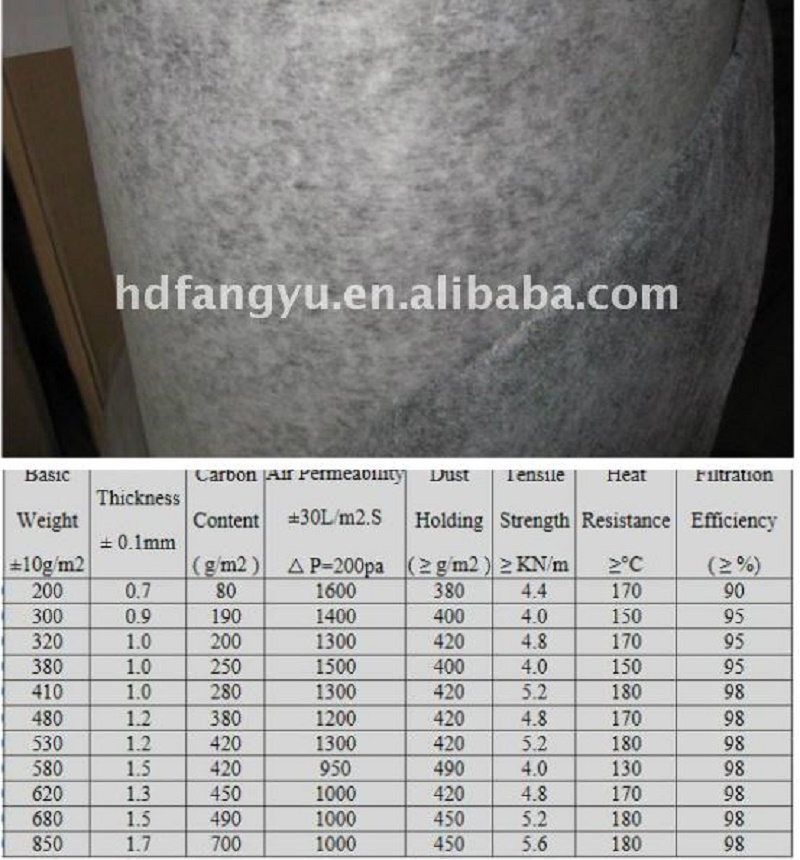

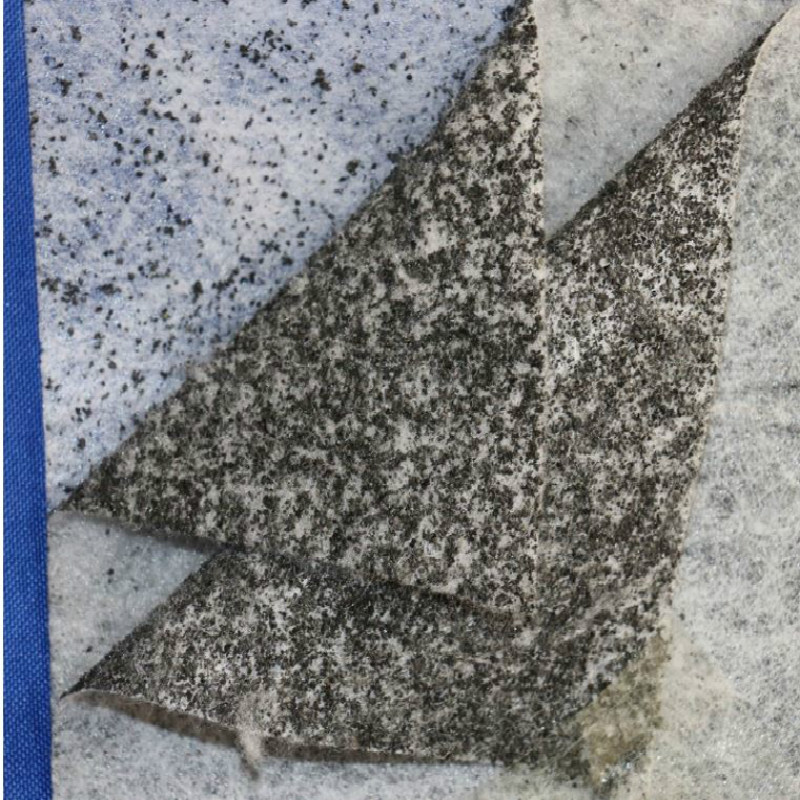

2. Technology Overview: Activated Carbon Composite Filter Media

Activated Carbon Composite Filter Media integrates granular or powdered activated carbon within composite structures, offering superior filtration, adsorption, and mechanical strength. This new-generation carbon filter media is engineered to maximize contaminant removal (VOCs, chlorine, organic pollutants).

- Material: Premium coconut shell or coal-based activated carbon, PET nonwoven support, thermally bonded composite layers.

- Manufacturing: Combinations of casting, CNC lamination, ultrasonic bonding, and precision dosing for consistent pore structure.

- Compliance: Meets international standards (ISO 9001, ISO 14001, ANSI/NSF, FDA).

- Service Life: 12,000~18,000 hours (dependent on application & flow rates).

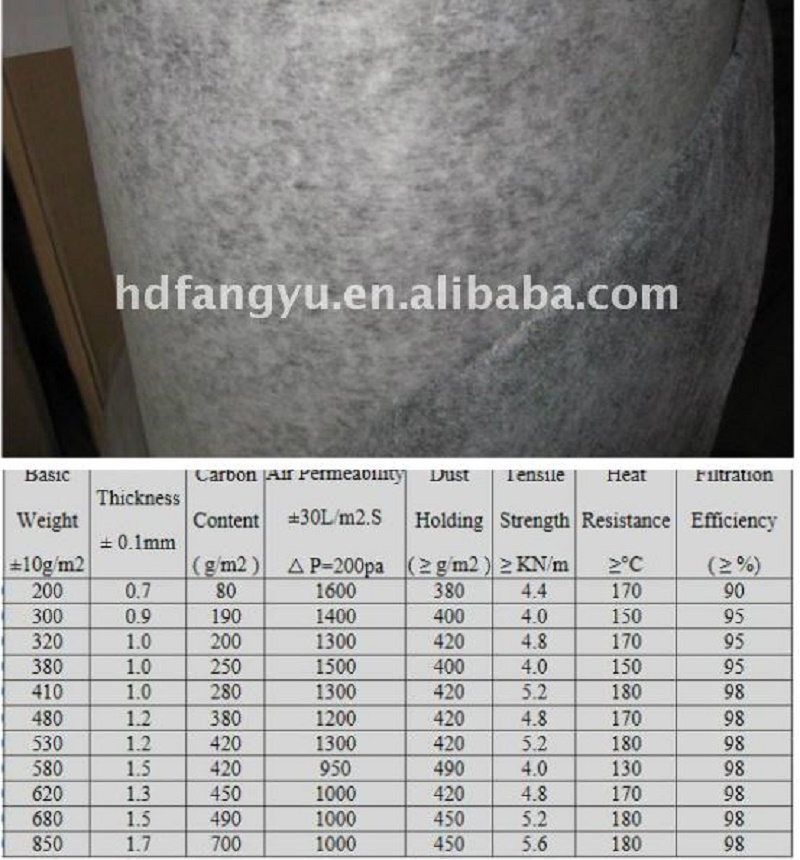

Technical Parameters Table — Activated Carbon Filter For Sale

| Parameter |

Specification |

Standard |

Test Result |

| Bulk Density (g/cm³) |

0.45~0.55 |

ISO 2857 |

0.51 |

| Iodine Number (mg/g) |

950~1250 |

ASTM D4607 |

1160 |

| Removal Efficiency (%) |

≥98 (Chlorine), ≥90 (VOCs) |

ANSI/NSF 42 |

99.2 / 93.4 |

| Particle Retention (μm) |

5, 10, 20 (customizable) |

ISO 16890 |

10 |

| pH Range |

2–11 |

ISO 10523 |

Pass |

| Service Life (hours) |

12,000~18,000 |

Industry Avg |

14,500 |

Note: Test results are based on laboratory evaluations; in-field efficiency may vary depending on inflow parameters and maintenance.

3. Manufacturing Flow Diagram

Activated Carbon Composite Filter Media Manufacturing Process

1

Raw Material Selection

(Coconut/Coal carbon)

→

2

Impregnation & Activation

(Steam/chemical method)

→

3

Particle Milling & Sieving

(Granular grading)

→

4

Composite Media Layering

(PET, Carbon, Binders)

→

5

CNC Cutting & Shaping

(Precision sizing)

→

6

Final Testing & QA

(ISO/ANSI)

→

7

Packaging & Warehousing

(OEM options available)

※ For video demonstration, view our process on

YouTube

4. Typical Application Scenarios & Technical Advantages

-

Water Treatment: Industrial/municipal drinking and process water—removal of chlorine, color, taste, and micro-pollutants.

-

Air Purification: HVAC, clean rooms, hospitals—VOC and odor removal with high flow, low-pressure drop.

-

Chemical Processing: Petrochemicals, metallurgy—adsorption of organic solvents, heavy metals.

-

Food & Beverage: Decolorization and deodorization during beverage & food processing (FDA compliant).

Activated carbon water filter media delivers superior performance via:

- High surface area (>1100 m²/g) — more adsorption sites.

- Uniform pore distribution — consistent filtration efficiency.

- Stable mechanical strength — minimized particle shedding.

- Chemical/thermal resistance — extended operational lifecycle.

Typical Service Life: Up to 18,000 hours with routine backflush/replacement cycles.

Certifications: ISO 9001, ANSI/NSF 61, FDA, WRAS (UK Drinking Water).

5. Supplier Comparison: Mainstream Activated Carbon Filter Media Providers

Extensive industry benchmarking enables end-users to choose the most reliable activated carbon filter suppliers. Below is an analysis of leading brands worldwide:

| Supplier |

Product Type |

Certification |

Iodine Number (mg/g) |

Unit Price (USD/kg) |

Major Applications |

| Jacobi Carbons (Sweden) |

Granular, Block |

ISO, NSF |

1050–1200 |

2.8–3.4 |

Municipal, Industrial Water |

| Calgon Carbon (USA) |

Powdered, Pellet |

ISO, ANSI |

950–1150 |

3.0–3.8 |

Water, Air, Food |

| Haycarb (Sri Lanka) |

Granular, Block |

ISO, NSF, WRAS |

1100–1200 |

2.4–3.1 |

Aquarium, Food, Air |

| Filtersmaterial.com |

Composite, OEM |

ISO, ANSI, FDA |

1160 |

2.2–2.9 |

Industrial, HVAC, Water |

| Donau Carbon (Germany) |

Granular, Pellet |

ISO, NSF |

950–1150 |

2.6–3.5 |

Petrochemical, Metal |

- Filtersmaterial offers superior value with factory-direct customization, high adsorption, and FDA/ISO compliance.

- Long-term industrial cooperation with Haier, Suez, and BASF (Service span: 15+ years).

6. Data Visualization: Technical Performance Comparison

Figure 1: Technical comparison of mainstream activated carbon filter for sale (Bulk Density, Iodine Number, Service Life)

Figure 2: Percentage breakdown of activated carbon filter media material types (2024)

Figure 3: Market demand trend for activated carbon filter for sale (2018-2024)

7. Customization & Solutions

Our Activated Carbon Composite Filter Media is available in a multitude of formats tailored to client tasks and regulatory requirements. Custom-cut, roll, panel, and cartridge forms with optional enhanced prefilters (HEPA, PP melt-blown) are offered.

- OEM/ODM: Branding, custom formulations, and size for unique system integrators.

- Industry Certification: Compliance with ISO, ANSI, WRAS, FDA, CE, RoHS, and more.

- Batch QA/QC: Lab analysis of adsorption rate, mechanical strength, dust content, and trace heavy metals.

- Packaging: As per industrial, commercial, or consumer market requirements (bulk, boxed, vacuum sealed).

Delivery Time: Rapid processing—10-15 working days typical for custom lots. Warranty: 18-month performance assurance, with after-sales technical support.

8. Application Cases & Real-World Experience

-

Haier (Home Appliance Manufacturing, China):

Filtersmaterial supplied activated carbon filter media for refrigerator air deodorizers, yielding an odor removal >95%, with average changeout period extended to 12 months. “We received ISO and FDA-compliant filters—great for low-maintenance OEM integration” (Head of Procurement).

-

Suez (Industrial Wastewater, France):

Custom composite filter modules reduced organic micro-pollutants by 92% in pilot tests, with no adsorbent leakage and minimized system pressure drop (EN 1822 certified).

-

BASF (Chemical Plant, Germany):

Used in air purification for solvent recovery—Test results: VOC removal efficiency 89~93% (as measured by TÜV Rheinland, 2022).

Case studies illustrate that choosing a qualified activated carbon filter for sale can improve operational efficiency, reduce downtime costs, and meet global regulatory standards.

9. Professional FAQ — Activated Carbon Filter Media

- Q1: What are the main material options for activated carbon filter media?

- The mainstream materials are coal-based carbon, coconut shell carbon (which offers higher microporosity), and wood-based carbon. Coconut shell carbon is preferred for drinking water and food use due to lower ash and higher iodine value.

- Q2: How is “Iodine Number” defined for activated carbon filters?

- Iodine Number expresses the mg of iodine adsorbed per gram (mg/g) of carbon — a key indicator of adsorption capacity, especially for small molecule contaminants per ASTM D4607.

- Q3: Can the filter media be customized to different particle retention sizes?

- Yes, standard retention sizes are 5, 10, and 20 microns, but can be tailored to 1-50 microns on demand (ISO 16890/EN 779 reference).

- Q4: What installation standards and methods are recommended?

- Install per manufacturer's guidelines and system compatibility (API 653, ISO 9001). Filter cartridges and cut panels are typically installed via quick-release clamps or sealed housings, ensuring no flow bypass.

- Q5: What is the recommended replacement cycle for industrial water/air use?

- Generally, 12–18 months or after a 30–40% drop in adsorption efficiency (monitored by pressure drop/inlet-outlet analysis). High-flow or high-pollution systems may require shorter cycles.

- Q6: Does activated carbon media meet food-grade or potable water use standards?

- Our media is certified to ANSI/NSF 61 and FDA standards, suitable for food processing, potable water, and pharmaceutical applications.

- Q7: What is the logistics and customer support process for international orders?

- Rapid order confirmation, express air/ocean shipping, full batch traceability, and 24/7 technical support channels ensure reliable after-sales experience.

10. Get a Quote or Technical Consultation

For activated carbon filter for sale bulk pricing, technical documents, or OEM project consultation, contact our experts. All inquiries receive a dedicated account manager and tailored datasheet within 24 hours.

Warranty: 18 months. 24/7 live support & onsite engineering available.

References & Further Reading