Hebei Fangyu Filters Material Technology Co., Ltd. is a leading meltblown filter media manufacturer with cutting-edge production facilities in Handan, China. Our R&D team specializes in developing high-performance filtration solutions for global industries.

Raw Material: Polypropylene

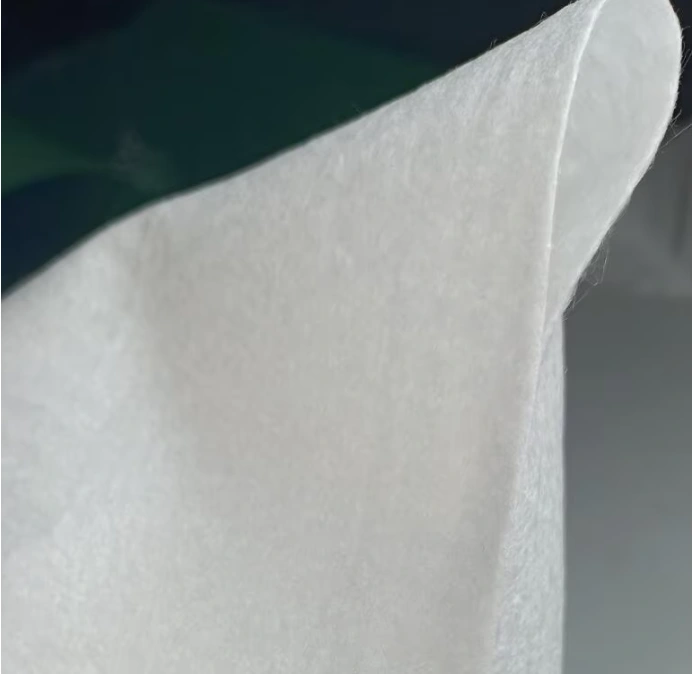

Process Technology: Melt-blown non-woven

Range of Efficiency: M5 ~ H11

This advanced composite melt blown filter media combines multiple filtration mechanisms to achieve superior particle capture efficiency with minimal pressure drop. The unique layered structure provides exceptional depth loading capacity ideal for demanding industrial applications.

View Product DetailsMeltblown filter material technology has revolutionized filtration across multiple sectors. In healthcare applications, these materials form the critical barrier layer in N95 respirators that capture over 95% of airborne particles. The COVID-19 pandemic dramatically increased global demand for medical-grade melt blown filter media, with production scaling from 10,000 tons/year pre-pandemic to over 60,000 tons/year at the peak.

Industrial applications utilize meltblown media for HVAC filtration systems, liquid filtration in petroleum processing, and semiconductor manufacturing where ultra-clean environments are essential. The automotive industry relies on these materials for cabin air filtration systems that remove particulate matter as small as 0.3 microns with 99.97% efficiency.

| Parameter | Standard Range | Premium Grade | Test Method |

|---|---|---|---|

| Fiber Diameter | 1-5 μm | 0.5-2 μm | SEM Microscopy |

| Basis Weight | 25-300 gsm | 40-150 gsm | ISO 536 |

| Filtration Efficiency (@0.3μm) | 85-99% | 95-99.97% | ASTM F2299 |

| Pressure Drop | 30-200 Pa | 20-95 Pa | ISO 5011 |

| Thickness | 0.2-2.0 mm | 0.3-1.2 mm | ISO 534 |

| Maximum Temperature | 90°C | 120°C | ISO 5630 |

Leading melt blown filter manufacturers like Hebei Fangyu have developed multi-beam extrusion technology that allows for precise control of fiber diameter distribution. Advanced die designs create layered media structures with gradient density for optimal depth filtration performance. Our proprietary technology achieves fiber diameters as small as 500 nanometers - approaching the theoretical limits of polypropylene extrusion.

The global market for meltblown filter material is projected to grow at 8.7% CAGR from 2023-2030, reaching $7.2 billion. Key growth drivers include:

Innovation in meltblown media now focuses on sustainable manufacturing with bio-based polypropylene and recycling programs that recover over 80% of production waste. Multi-functional media incorporating antimicrobial additives are gaining market share, particularly in healthcare environments.

Thickness:0.2-6 mm or Customized

Strand Thickness:0.5-8mm

Swd:2.5-100mm Lwd: 4.5-200mm

Surface Treatment:Powder Coated,Galvanized

MATERAL: PHENOLIC PAPER

MELT-BLOWN PBT

NON-WONEN LAMINATES

DIESEL FUEL FINE FILTERATION GRADE

APPLICATION : FUEL OIL WATER SEPERATION FILTER MEDIA

Material: Electrostatic cotton with activated carbon

PET/PP with Activated Carbon

Basic weight: 200-800g/m2

Application: Cabin Air Filters Panel Air Filters, Filter Cartridge, etc.

RAW MATERIAL: Polypropylene

PROCESS TECHNOLOGY: Melt-blown non-woven

RANGE OF EFFICIENCY: M5 ~ H11

Email to this supplier