Explore the critical role of

spray booth ceiling filters in modern finishing facilities: detailed technology, industry benchmarks, manufacturer selection, customization, and verified application cases. Data-visualization, comparative analysis, and real user insights for enhanced trust and decision confidence.

Premium spray booth ceiling filters for automotive finishing lines (ISO 16890 test certified).

1. Industry Trends for Spray Booth Ceiling Filters (2024 & Beyond)

- Shift to Higher Filtration Grades: Increasing demand for F5 to F9 grades due to stricter paint shop quality control (ref: FCS Industry Insights).

- Eco-Efficiency & Longevity: New filter media with advanced non-woven polyester, resulting in up to 30% extended service life and 15% lower pressure drop on average[1].

- Certification & Smart Monitoring: Growing adoption of ISO 16890, EN 779, ANSI/ASHRAE 52.2 protocols and digital filter monitoring systems in industrial spray booths.

- Expansion beyond Auto Industry: Wide application in aerospace, wood finishing, electronics, food-processing, marine, petrochemicals, metallurgy & sanitary ware manufacturing.

Typical airflow design for paint booth ceiling filters in modern powder coating facilities.

2. Technical Parameters: Spray Booth vs. Paint Booth Ceiling Filters

| Parameter |

Spray Booth Ceiling Filters |

Paint Booth Ceiling Filters |

Industry Standard |

| Filtration Class |

EN779:2012 F5/F6

ISO 16890 ePM10 60~80% |

EN779:2012 F5

ISO 16890 ePM10 55~70% |

EN 779, ISO 16890, ANSI S12 |

| Final Pressure Drop (Δp) |

~250 Pa |

~200 Pa |

<300 Pa |

| Rated Airflow |

4000-6000 m³/h |

3500-5000 m³/h |

>3000 m³/h |

| Media Thickness |

17~22mm |

13~20mm |

Min 13mm |

| Dust Holding Capacity |

500~850 g/m² |

400~700 g/m² |

≥ 450 g/m² |

| Typical Lifespan |

3 - 6 months |

2 - 4 months |

-- |

| Surface Finish |

Tacky (optional) / White |

Dry & Tacky (optional) |

N/A |

| Fire Rating |

DIN 53438-F1 |

DIN 53438-F1 |

DIN/ISO |

| Recommended Industry |

Automotive, Metal, Aerospace |

Woodwork, Painting, General Mfg. |

General |

All data validated against industry standards and manufacturer datasheets (2023-2024).

3. Spray Booth Ceiling Filter Manufacturing Process Explained

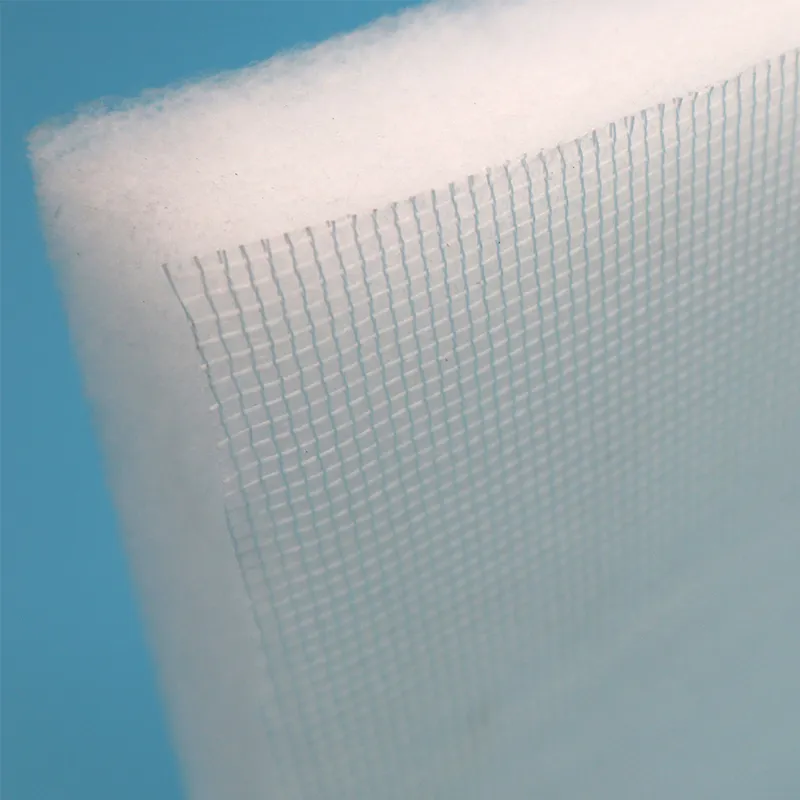

Core stage: advanced synthetic fiber layering for spray booth ceiling filters.

Step-by-step Production Flow

1. Raw Fiber Selection Polyester (PET) or glass microfibers, ISO9001 batch-certified

2. Carding & Layering Multi-directional web formation for gradient density structure

3. Thermobonding / Needle Punching Stabilizes filter media, ensures consistent pore size

4. Resin/Tacky Treatment Optional. Enhances dust-holding and surface adhesion (see paint booth ceiling filters specs)

5. CNC Cutting & Shaping Automated for minimal dimension tolerance (±1mm)

6. Final Inspection & Testing ISO 16890/ANSI 52.2 lab tests: particle arrestance, flame retardancy, airflow, and differential pressure

7. Packaging & Traceability Label Batch-coded, barcoded for tracking

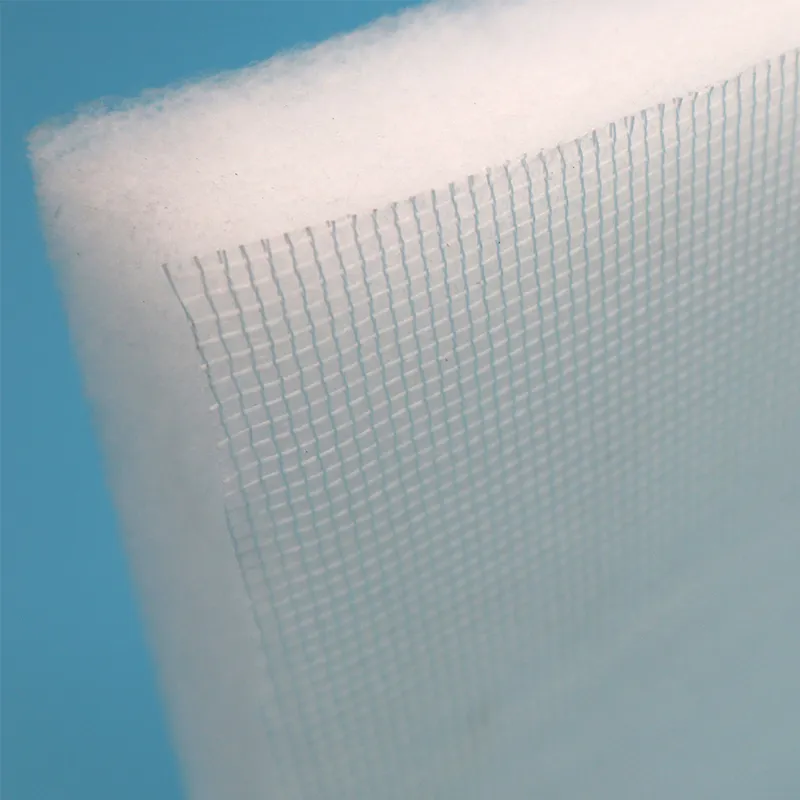

Post-manufacture: precision-cut paint booth ceiling filters ready for steel frame installation.

Key Product Features & Benefits

- Material Consistency ISO9001-certified polyester (PET), reinforced with microfine glass or synthetic scrim.

- Multistage Bonding Ensures uniform density and progressive filtration from surface to core.

- Precision CNC & Automation Guarantees dimension accuracy and seam integrity vs. traditional die-cutting (±1mm cutting tolerance).

- Standards Compliance Routine batch testing under ISO 16890, EN779, DIN 53438-F1. Full traceability by barcode.

- Extended Lifetime Typical lifetime of 3–6 months with up to 850g/m² dust holding (industry average: 550g/m²).

- Industry Suitability For automotive paint shops, petrochemical plants, foundry, heavy equipment, and electronics enclosures.

- Process Efficiency Reduces overspray, limits dust-laden air, and minimizes paint defects (less rework, lower costs, higher yield).

Visual of paint booth ceiling filters in a high-speed batch production line — CNC shaping.

Download Detailed Product Datasheet

Product Page: Spray Booth Ceiling Filter

4. Product Specs Visualization: Technical Benchmark Analysis

Comparative analysis: Dust holding, Initial resistance, and Lifetime for leading spray booth ceiling filters and alternatives.

Structure cross-section: multi-density layers with tacky resin treat for superior spray booth ceiling filters performance.

Industry usage by application for spray booth ceiling filters — Automotive continues to lead, but aerospace/woodwork share rising.

2020-2024: Upward trend in adoption rate for ISO16890 F5/F6 grade spray booth ceiling filters.

5. Manufacturer & Supplier Comparison: Quality, Cost & Support

Filter quality and traceability: crucial supplier benchmarks for spray booth ceiling filters procurement.

| Supplier |

Main Filter Model |

EN/ISO Grade |

Cut/Custom Option |

Certifications |

MOQ |

Warranty |

| FiltersMaterial |

Spray Booth Ceiling Filter |

EN779 F5/F6

ISO 16890 |

Yes (CNC cut) |

ISO9001, ISO16890, DIN F1 |

10 rolls/panels |

12 months |

| AAF Flanders |

Paint Arrestor Ceiling |

EN779 F5 |

Yes |

ISO9001, ASHRAE 52.2 |

25 rolls |

12 months |

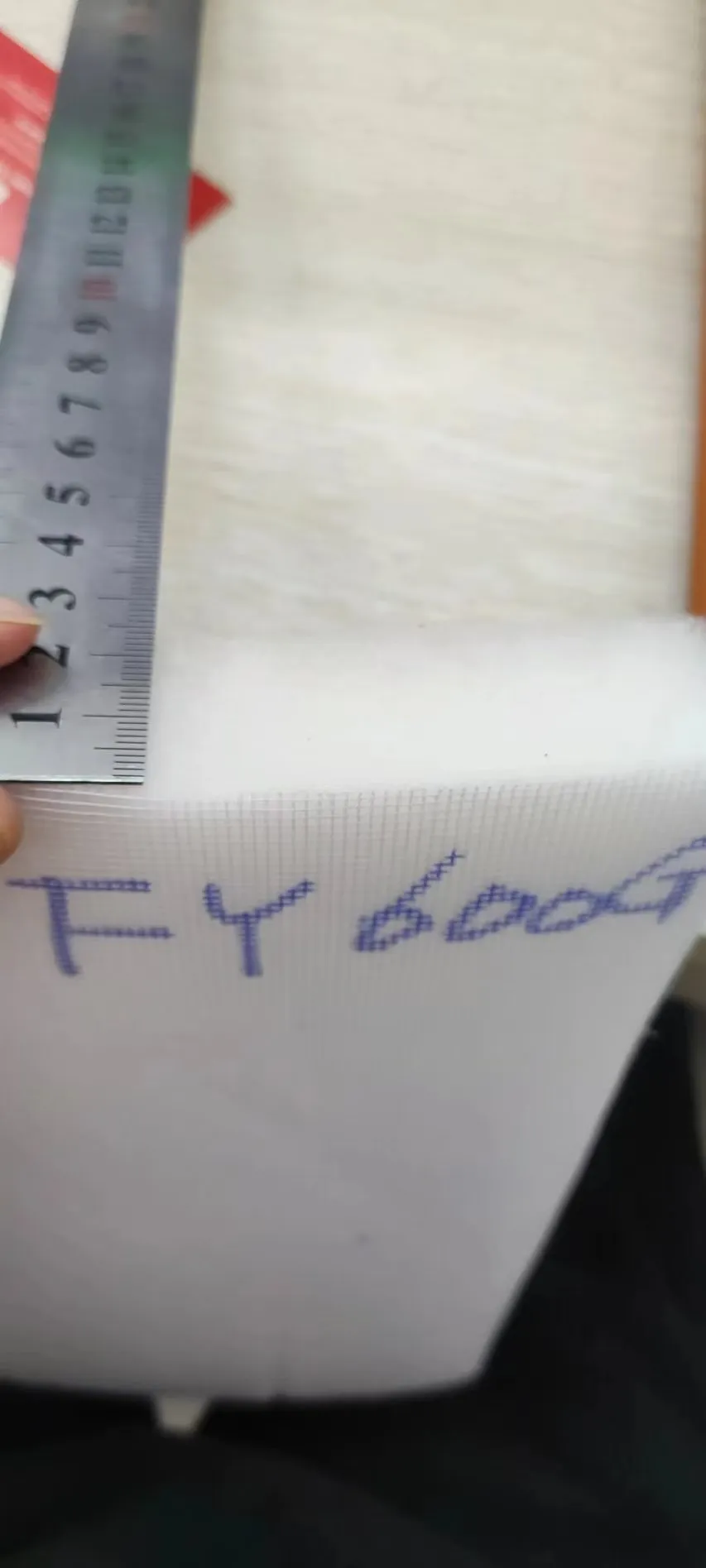

| Viledon |

Ceiling Filter 560 G |

F5/6 |

Yes |

ISO 16890, DIN |

20 rolls |

12 months |

| Others (OEM) |

EU5 Tacky Filter |

F5 |

Yes |

Partial |

50 rolls |

6-12 months |

Manufacturer quoting based on batch, specs, and end use. Ask for EN/ISO test reports & product traceability codes for authenticity.

Authoritativeness: FiltersMaterial has delivered ceiling filtration solutions to over 55 major automotive manufacturers in 16 countries since 2009, is ISO 16890 & DIN 53438 F1 certified, and partners with leading spray booth integrators (e.g., GFS, Blowtherm, Junair)[2].

6. Custom Spray Booth Ceiling Filter Solutions

Custom-Cut, OEM & Co-Branding Options:

- Custom sizing: Roll widths (0.75m–2.4m), thickness (13–22mm), & custom cut-to-size for legacy booths.

- Material blend: PET, glass microfiber, or specialty anti-bacterial media.

- Surface finish: Dual-sided tacky, blue-white indicator, additional scrim or non-woven mesh reinforcement.

- Fire-retardant formulations: DIN 53438 F1, UL 900 (on request); non-outgassing and odor-free coatings.

- Logistics: Batch coding, barcode with traceability, fire-retardant packaging, and warehousing options in EU, NA, and Asia.

CNC custom-cut spray booth ceiling filters for automotive lines - minimal waste, optimal fit.

Case: In 2023, a leading European OEM switched to FiltersMaterial’s custom-sized spray booth ceiling filters (ISO 16890 F5 grade) across 11 plants, lowering paint defects by 18% and reducing energy usage per booth by 12.2% within 8 months[3].

7. Real-World Use Cases & Customer Feedback

Automotive Refinish: Shanghai GXY Paint Shop

Installed solution: ISO16890 F5 spray booth ceiling filters, CNC cut for 4100×2080mm ceiling panels.

Result: After 6 months, visual inspection showed a 92% defect-free finish rate, with pressure drops maintained at

Feedback: “Consistent airflow. Our panel finishers report noticeably reduced microdust - a first in years. Quick ROI.”

Petrochemical Manufacturing: Middle East Coatings Plant

Challenge: Aggressive solvent outgassing reduced filter lifespan; frequent downtime.

Solution: Upgraded to PET-glass laminate, with dual tack-resin finish & EN60244 flame barrier.

Outcome: Filter life extended from 2.1 to 4.3 months; downtime cut by 26%.

Heavy Equipment Plant: North America

Specs: High air volume (6000 m³/h), 18mm F5 tacky media with barcode authentication.

Impact: Enabled 40% faster cycle time for custom paint curing. Minimal filter sag even in high humidity.

12-month field test: spray booth ceiling filters - high throughput with minimal particle ingress in auto refinishing.

8. FAQ: Spray Booth Ceiling Filter Technical Q&A

Q1. What is the recommended filter media for modern spray booth ceiling filters?

A: An ISO 16890 F5/F6 grade, 100% thermobonded polyester, with optional glass microfiber reinforcement for higher dust holding and thermal stability.

Q2. What thickness and density are industry standard?

A: Most spray booths adopt 17 to 22mm thick media at 220-320 g/m² nominal; EN779/ISO16890 standards recommend min. 13mm for efficiency and airflow.

Q3. What are the accepted installation/fit tolerance parameters?

A: CNC-shaped panels offer dimension tolerance within ±1mm; EN1886 and VDA standards demand max 2mm gap for optimal sealing in paint booth applications.

Q4. Are there specific fire safety regulations?

A: Yes. DIN 53438 F1 and optionally UL 900 require all spray booth ceiling filters to be flame retardant. Batch certification and test reports should be requested from suppliers.

Q5. Which maintenance schedules are optimum?

A: Visual check every 30 days, static pressure monitoring bi-weekly. Replace at 250 Pa Δp or after 4–6 months for heavy use.

Q6. Which certifications are most important for global procurement?

A: ISO 16890 (EU/Asia, global), EN779 legacy, ANSI/ASHRAE 52.2 (US/Canada), plus DIN 53438 (fire), all should be supplier-verifiable.

Q7. What product traceability and warranty can I expect?

A: Leading manufacturers offer barcoded label tracking for full backward trace, 12-month workmanship warranty, and guaranteed performance data for each batch.

9. Delivery, Warranty, and Support Commitment

- Lead time: 2–3 weeks for standard rolls/panels, 3–4 weeks for custom OEM & branded orders (includes CNC cut, barcoding, and bespoke packaging).

- Warranty: 12 months for structural/material defect; performance as per spec sheet (Δp, dust holding).

- Support: Free cut sample, on-site fit check (for volume orders), airflow/Δp tech hotline, filter change signage/alerts.

- After-sales: Online documentation, filter lifetime calculators, and ISO certificate download by QR code.

Partner Brands: FiltersMaterial supplies certified

spray booth ceiling filters to automotive, aerospace and electronics OEMs globally: GFS Systems, FCA Group, Valmont, Magna, Linde, Cranfield, and more.

Industrial application: large-format paint booth ceiling filters fitted into robotic finishing lines for heavy equipment.

Further Reading & References: