Keywords: synthetic filter media, synthetic air filter media, synthetic air filter media rolls, synthetic filter roll

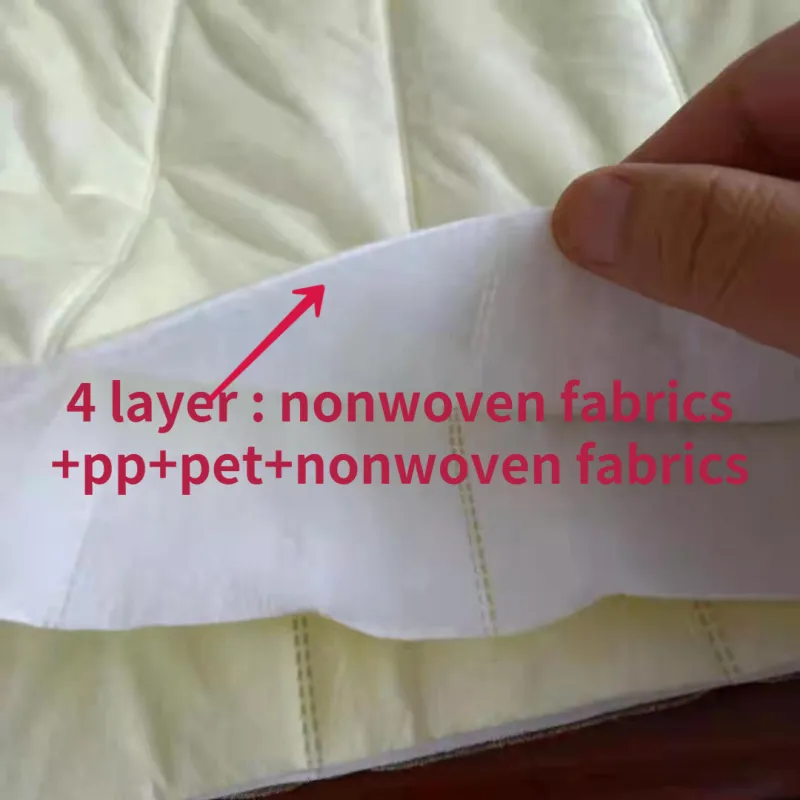

Synthetic filter media refers to filter materials engineered from man-made fibers such as meltblown polypropylene, polyester, and synthetic composites. These materials are commonly used in air filtration systems because of their uniform fiber structure, excellent chemical resistance, high dust holding capacity, and long service life.

Types include synthetic air filter media, synthetic air filter media rolls, and synthetic filter roll, each designed for specific HVAC and industrial filtration needs.

| Parameter | Synthetic Pocket Filter Media | Fiberglass Media | Cellulose Media |

|---|---|---|---|

| Primary Material | 100% Polypropylene / Polyester | Borosilicate Glass | Natural Cellulose Fibers |

| Efficiency Grades | M5, M6, F7, F8, F9 (ISO ePM1 50%-90%) | M6 - F9 | G2 - G4 (Low) |

| Typical Thickness | 4mm ~ 25mm | 3mm ~ 22mm | 5mm ~ 15mm |

| Initial Pressure Drop (Pa) | 35–70 Pa (@0.25m/s) | 40–90 Pa | 45–80 Pa |

| Dust Holding Capacity (g/m²) | 370–600 | 250–420 | 90–180 |

| Moisture Resistance | Excellent (Hydrophobic) | Poor | Very Poor |

| Fire Resistance | Meets DIN 53438 F1, UL 900 | Meets DIN 53438, UL 900 | Poor |

| Service Life | 1–3 years | 6–18 months | <12 months |

| Operating Temp. | Up to 80°C | Up to 65°C | Up to 50°C |

| Standard Compliance | ISO 16890, EN 779:2012 | EN 779 | G2/G3 |

| Media Type | Synthetic | Fiberglass | Cellulose |

|---|---|---|---|

| Dust Holding | 600 | 420 | 180 |

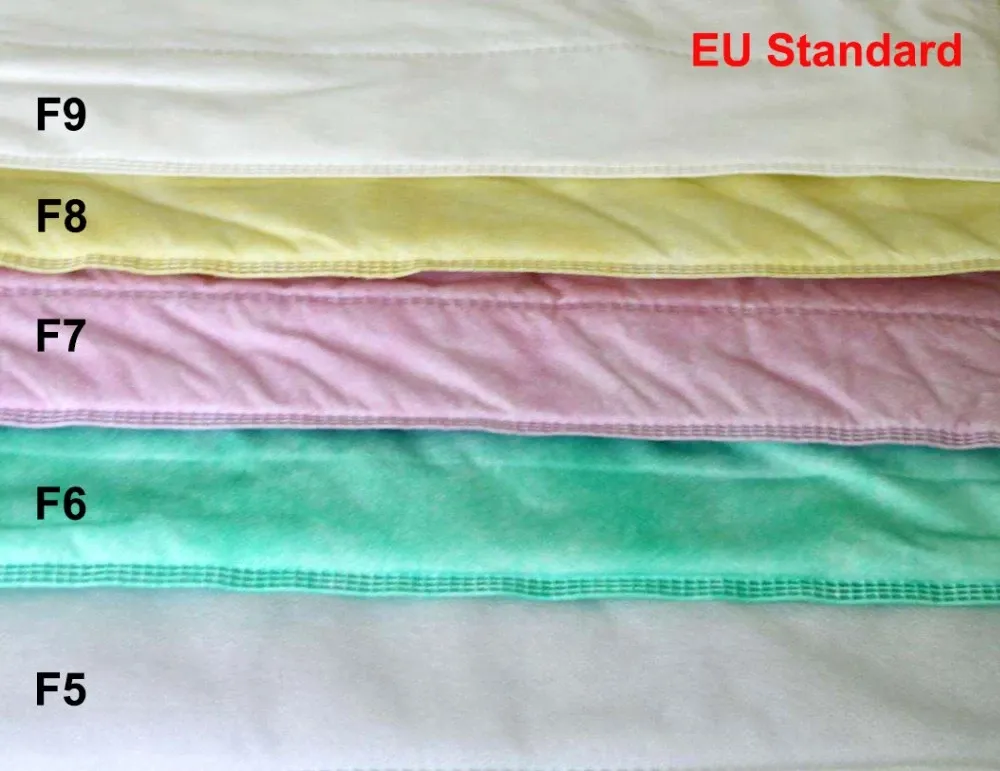

| Grade | Color | Thickness (mm) | Efficiency (EN 779) | Efficiency ISO16890 | Initial Pressure Drop (Pa) | Dust Holding (g/m²) |

|---|---|---|---|---|---|---|

| M5 / F5 | Green | 5–7 | 40–60% | ePM10 50–65% | 37 | 350 |

| M6 / F6 | Pink | 7–9 | 65–80% | ePM2.5 70% | 42 | 410 |

| F7 | Yellow | 8–10 | 80–90% | ePM1 75–80% | 48 | 510 |

| F8 | Blue | 10–12 | 90–95% | ePM1 85% | 52 | 580 |

| F9 | White | 12–15 | > 95% | ePM1 90% | 56 | 600 |

| Manufacturer | Country | Core Brand/Certifications | Main Product Types | Lead Time | Industry Focus |

|---|---|---|---|---|---|

| Filtersmaterial.com | China | ISO 16890, EN779, SGS, FDA, RoHS | Synthetic filter media, pocket filter rolls, HEPA support media | 7–18 days | HVAC, Industrial, Automotive |

| AAF Flanders | USA | UL 900, ISO 9001 | Glass/synthetic air filter rolls, high-efficiency bags | 14–28 days | Industrial, Cleanrooms |

| Freudenberg Filtration | Germany | EN 779, ISO 16890 | Polyester/premium synthetic media | 10–22 days | Automotive, HVAC, Pharma |

| Camat | Italy | ISO 16890, CE | Pre-filter & pocket filter rolls | 12–30 days | HVAC, Industry |

Thickness:0.2-6 mm or Customized

Strand Thickness:0.5-8mm

Swd:2.5-100mm Lwd: 4.5-200mm

Surface Treatment:Powder Coated,Galvanized

MATERAL: PHENOLIC PAPER

MELT-BLOWN PBT

NON-WONEN LAMINATES

DIESEL FUEL FINE FILTERATION GRADE

APPLICATION : FUEL OIL WATER SEPERATION FILTER MEDIA

Material: Electrostatic cotton with activated carbon

PET/PP with Activated Carbon

Basic weight: 200-800g/m2

Application: Cabin Air Filters Panel Air Filters, Filter Cartridge, etc.

RAW MATERIAL: Polypropylene

PROCESS TECHNOLOGY: Melt-blown non-woven

RANGE OF EFFICIENCY: M5 ~ H11

Jul,2025,31

Jul,2025,31

Jul,2025,31

Jul,2025,31

Email to this supplier