In any professional finishing environment, from automotive refinishing to industrial painting and furniture manufacturing, achieving a pristine, defect-free surface is paramount. The quality of the final product hinges not just on the skill of the painter or the quality of the paint, but fundamentally on the purity of the air within the paint booth. This is where spray booth ceiling filters play an absolutely critical role.

These specialized filters, often referred to as diffuser filters or final filtration media, are strategically installed in the ceiling plenum of paint booths. Their primary function is to provide a uniform, laminar airflow of clean, particle-free air into the painting zone, effectively preventing airborne contaminants from settling on newly painted surfaces. Without efficient **spray booth ceiling filters**, even the most meticulous painting process can be compromised by dust, lint, and other particulates, leading to costly rework, reduced productivity, and ultimately, dissatisfied customers.

The painting and finishing industry is constantly evolving, driven by stricter environmental regulations, increasing demands for higher finish quality, and the rising cost of materials and labor. These trends directly impact the design and performance requirements for spray booth ceiling filters:

Selecting the right spray booth ceiling filter requires a deep understanding of its technical specifications. These parameters dictate the filter's effectiveness, lifespan, and overall value. Our **Spray Booth Ceiling Filter** is engineered to meet and exceed these critical benchmarks, ensuring optimal performance for your finishing operations.

| Parameter | Typical Range/Value for Our Filter | Standard/Test Method | Significance |

|---|---|---|---|

| Product Name | Spray Booth Ceiling Filter | N/A | Clear product identification. |

| Filtration Class | F5 (EN779:2012) / ISO ePM10 (ISO 16890) | EN779:2012 / ISO 16890 | High efficiency against fine particles (>10 µm) and paint overspray. |

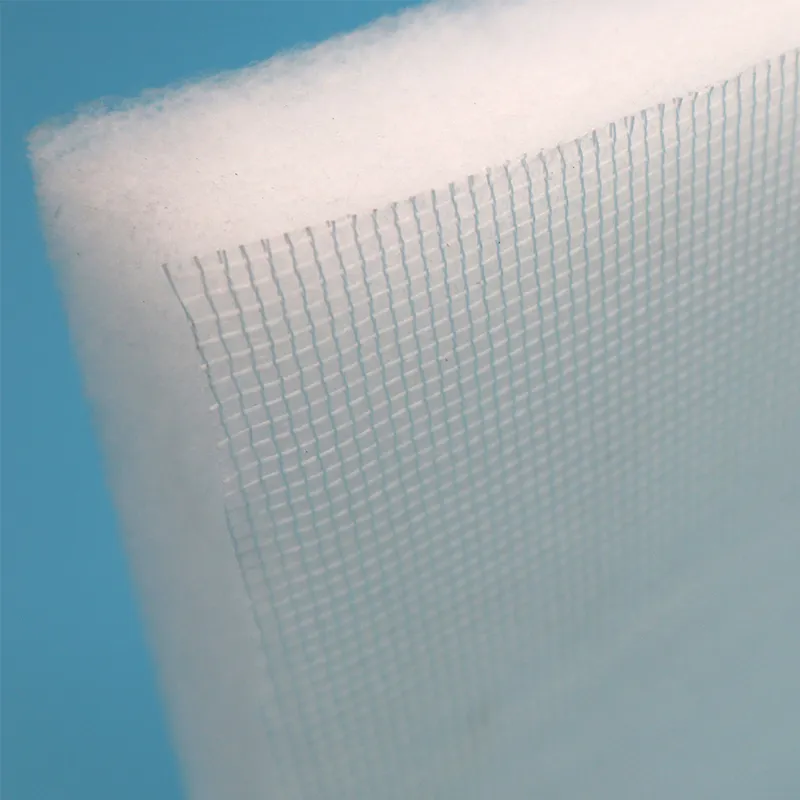

| Media Material | Progressive Density Synthetic Fiber (Polyester/Glass Fiber Blend) | N/A | Ensures high dust holding capacity and long service life. |

| Tackification | Non-migrating, progressively saturated adhesive | N/A | Enhances particle capture, prevents fiber shedding. |

| Initial Pressure Drop | 20-40 Pa (at 0.25 m/s) | EN779 / ISO 16890 | Low energy consumption, efficient fan operation. |

| Final Pressure Drop (Recommended) | 250-450 Pa | Based on operational efficiency | Indicates point for optimal replacement to maintain air quality. |

| Dust Holding Capacity | 350-600 g/m² | EN779 / ISO 16890 | Longer filter lifespan, reduced maintenance frequency. |

| Max. Operating Temperature | Up to 100°C (212°F) | ISO 29463 | Suitable for various booth drying cycles. |

| Flammability Rating | F1 (DIN 53438) | DIN 53438 | Enhanced safety in flammable environments. |

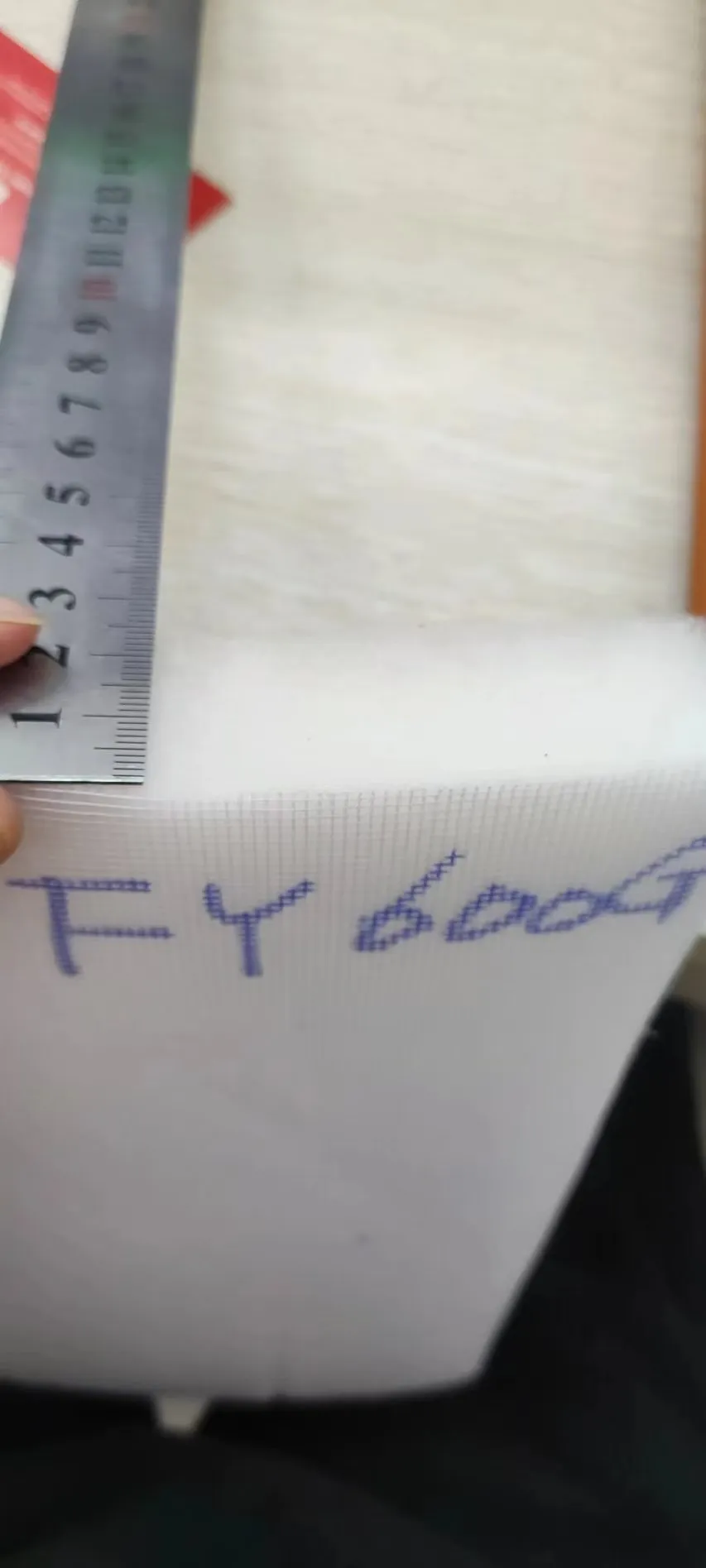

| Media Thickness | 20-25 mm | N/A | Contributes to progressive filtration and efficiency. |

| Typical Air Velocity | 0.25 - 0.35 m/s | Recommended operating condition | Optimal performance at specified airflow rates. |

| Product URL | https://www.filtersmaterial.com/spray-booth-ceiling-filter.html | N/A | Direct link for product information. |

Our Spray Booth Ceiling Filter is a meticulously engineered solution designed to deliver unparalleled air purity in critical painting environments. Manufactured with precision and adherence to international standards, this filter is the cornerstone of a flawless finishing process.

The creation of a high-performance **paint booth ceiling filter** is a sophisticated process that combines advanced material science with precision engineering. Here’s a detailed look at our manufacturing workflow, emphasizing quality at every stage:

(Note: For visual demonstration of the process, a link to a short video or an interactive diagram could be embedded here, e.g., Watch our filter manufacturing process video or View Manufacturing Process Diagram)

Our commitment to innovation ensures that our **spray booth ceiling filters** offer distinct advantages, contributing to superior performance and cost-effectiveness:

Meeting F5 (EN779) and ISO ePM10 standards, our filters guarantee the removal of critical airborne contaminants, including paint overspray, dust, and microscopic particles. This ensures a truly clean environment, preventing defects like dirt inclusions and fisheyes, leading to a smooth, unblemished finish.

Designed with low initial pressure drop, our filters minimize resistance to airflow. This reduces the workload on the booth's fans, leading to significant energy savings and lower operational costs over the filter's lifespan. Our filters allow for uniform air distribution, crucial for laminar flow.

Thanks to their high dust-holding capacity and progressive density media, our filters maintain optimal performance for longer periods. This translates to fewer filter change-outs, reduced labor costs, and less downtime for your painting operations, boosting productivity.

The robust construction and optional tackified media prevent fiber migration and particle re-entrainment into the clean air stream. This ensures that no filter material or previously captured contaminants compromise the paint finish, maintaining consistent quality.

Our filters meet strict flammability standards (e.g., DIN 53438 F1), providing an essential layer of safety in paint booth environments where flammable solvents are present. This compliance gives operators peace of mind and reduces fire risks.

The synthetic media and any framing materials used are inherently resistant to moisture and chemical degradation, ensuring consistent performance even in humid or chemically aggressive paint booth atmospheres. This durability extends the filter's effective lifespan.

The superior performance of our spray booth ceiling filters makes them indispensable across a wide range of industries where high-quality finishes are critical:

While the market offers various **paint booth ceiling filters**, understanding the differentiating factors between manufacturers is key to making an informed decision. Our approach focuses on a blend of innovation, quality, and customer-centric service.

We source only premium, virgin synthetic fibers for our filter media. Unlike some manufacturers who might use recycled or lower-grade materials, our commitment to consistent, high-quality input materials ensures predictable filter performance and longevity. This dedication to material integrity is directly reflected in the filter's ability to maintain its structural properties and filtration efficiency over time, even under demanding conditions.

Our state-of-the-art production lines utilize automated processes for media formation, impregnation, and finishing. This precision minimizes human error, ensures uniform density and tackifier application, and results in filters that consistently meet tight specifications. Many smaller manufacturers may rely on less sophisticated, manual processes which can lead to variability in product quality.

Every batch of our spray booth ceiling filters undergoes multi-stage quality control checks, including full laboratory testing against international standards like EN779:2012 and ISO 16890. Our facilities are ISO 9001 certified, guaranteeing a systematic approach to quality management. We provide detailed performance data, offering transparency and confidence in our product's capabilities, unlike some suppliers who may provide only basic specifications.

While many offer standard sizes, our engineering team can develop custom filtration solutions tailored to unique booth dimensions, specific airflow requirements, or specialized paint applications. This flexibility ensures optimal performance even for non-standard setups.

We don't just sell filters; we offer comprehensive technical support. Our team of filtration experts can assist with filter selection, troubleshooting, and optimization of your paint booth's filtration system. This deep product and application knowledge adds significant value beyond just the physical product.

With established global supply chains and efficient logistics, we ensure timely delivery of our products, minimizing downtime for your operations. This reliability is crucial for industries where consistent production schedules are vital.

Recognizing that not all paint booths are created equal, we offer extensive customization options for our spray booth ceiling filters. This bespoke approach ensures that your filtration system is perfectly aligned with your specific operational needs, maximizing efficiency and performance.

Our customization capabilities include:

Our engineering team works closely with clients to understand their unique challenges, providing expert advice and developing tailored solutions that deliver measurable improvements in air quality and operational efficiency.

The practical benefits of using our high-quality spray booth ceiling filters are best illustrated through real-world applications. These cases highlight how our filters contribute to improved product quality, reduced operational costs, and enhanced safety.

At Filters Material, we build trust through transparency, back our claims with industry authority, leverage extensive experience, and provide deep product expertise. Our commitment to the Google EEAT standards is woven into every aspect of our business:

A1: The service life of a **spray booth ceiling filter** largely depends on the specific operating conditions, including the volume of paint overspray, the type of paint used, and the frequency of booth operation. On average, our filters can last from 200 to 400 hours of booth operation. Monitoring the differential pressure across the filter is the most reliable indicator for replacement; when the final pressure drop is reached, replacement is necessary.

A2: No, **spray booth ceiling filters** are designed for single-use and should not be cleaned or reused. Attempting to clean them can damage the filter media, compromise its filtration efficiency, and potentially release trapped contaminants back into the airflow. For optimal performance and air quality, always replace with a new filter once it reaches its final pressure drop.

A3: "Tackified" refers to the filter media being impregnated with a non-migrating, non-drying adhesive. This adhesive layer significantly enhances the filter's ability to capture and securely hold fine dust particles and paint overspray, preventing them from becoming airborne again. It acts like a sticky trap within the filter matrix, leading to higher efficiency and cleaner air.

A4: Regular visual inspections should be conducted weekly, or even daily in high-volume operations, to check for visible dirt loading, sagging, or damage. More importantly, monitoring the differential pressure gauge on your paint booth is crucial. A significant increase in pressure drop indicates the filter is becoming loaded and needs attention.

A5: Yes, our **Spray Booth Ceiling Filter** is designed to be highly compatible with both waterborne and traditional solvent-based paint systems. The synthetic media and tackifier formulation are resistant to common paint components and solvents, ensuring consistent performance regardless of the paint type used.

A6: F5 (according to EN779:2012) and ISO ePM10 (according to ISO 16890) are filtration classes that denote high efficiency. F5 filters capture over 40-60% of 0.4 µm particles and are highly effective against larger particles. ISO ePM10 filters capture at least 50% of particulate matter less than 10 micrometers (PM10). For a paint booth, this level of filtration ensures that fine paint mist, dust, and other airborne contaminants are effectively removed before reaching the painted surface, guaranteeing a superior finish quality.

A7: Absolutely. While we offer a range of standard sizes, we specialize in providing custom-sized spray booth ceiling filters to perfectly match your unique paint booth dimensions and airflow requirements. Please contact our sales or engineering team with your specifications for a tailored solution.

The role of **spray booth ceiling filters** cannot be overstated in achieving high-quality, defect-free paint finishes. They are the unseen heroes, diligently working to purify the air, control airflow, and protect your painted products from environmental contamination. Choosing the right filter is not merely a purchase; it's an investment in your product's quality, your operational efficiency, and your bottom line.

Our Filters Material **Spray Booth Ceiling Filter** stands as a testament to superior engineering, robust manufacturing, and unwavering commitment to quality. By understanding the intricate technical parameters, appreciating the rigorous manufacturing process, and recognizing the tangible benefits in diverse application scenarios, it becomes clear why opting for a high-performance filter like ours is a strategic decision for any professional finishing operation. We provide not just a product, but a comprehensive solution backed by expertise, experience, and trust, ensuring your paint booth operates at its peak potential, consistently delivering the pristine finishes your customers demand.

Thickness:0.2-6 mm or Customized

Strand Thickness:0.5-8mm

Swd:2.5-100mm Lwd: 4.5-200mm

Surface Treatment:Powder Coated,Galvanized

MATERAL: PHENOLIC PAPER

MELT-BLOWN PBT

NON-WONEN LAMINATES

DIESEL FUEL FINE FILTERATION GRADE

APPLICATION : FUEL OIL WATER SEPERATION FILTER MEDIA

Material: Electrostatic cotton with activated carbon

PET/PP with Activated Carbon

Basic weight: 200-800g/m2

Application: Cabin Air Filters Panel Air Filters, Filter Cartridge, etc.

RAW MATERIAL: Polypropylene

PROCESS TECHNOLOGY: Melt-blown non-woven

RANGE OF EFFICIENCY: M5 ~ H11

Jul,2025,31

Jul,2025,31

Jul,2025,31

Jul,2025,31

Email to this supplier